Feather tip glue coating process for shuttlecock processing

A badminton and hair tip technology, which is applied in the field of rubber tip coating technology for badminton processing, can solve the problems of difficult to distinguish duck feathers and goose feathers, scattered feather tips, and limited supply of raw materials, and achieve good aging resistance and increase hydrophilicity , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

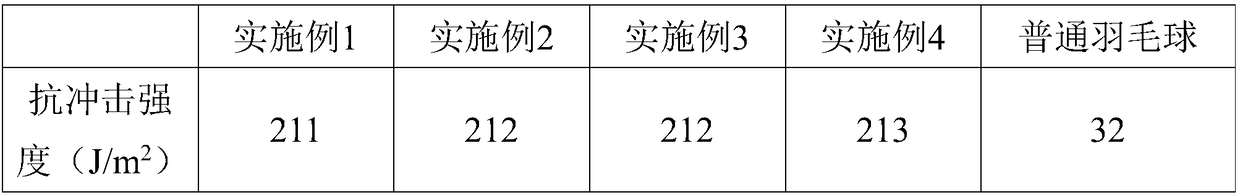

Examples

Embodiment 1

[0033] A technique for dipping hair tip glue for badminton processing, comprising the following steps:

[0034] (1) After the badminton is finished, check whether the feather tips are distributed equidistantly, and the qualified products that are equidistantly distributed enter the next process;

[0035] (2) Put the viscose into the heating body of the circular dispenser for heating;

[0036] (3) Put the badminton on the circular dispenser fixture, set the program to automatically adjust the height of the dispensing syringe, so that the height of the dispensing syringe from the hair tip is 0.5mm;

[0037] (4) Set the badminton speed to 30r / min, and the dispensing speed to 2mm / s. During the continuous rotation of the shuttlecock, stick the glue on the tip of the hair. Stop sticking the glue every revolution to dry the glue. Stop sticking glue at 0.6mm;

[0038] (5) Put the glued badminton into 0.8Mpa nitrogen and let it stand for 20 minutes.

Embodiment 2

[0040] A technique for dipping hair tip glue for badminton processing, comprising the following steps:

[0041] (1) After the badminton is finished, check whether the feather tips are distributed equidistantly, and the qualified products that are equidistantly distributed enter the next process;

[0042] (2) Put the viscose into the heating body of the circular dispenser for heating;

[0043] (3) Put the badminton on the circular dispenser fixture, set the program to automatically adjust the height of the dispensing syringe, so that the height of the dispensing syringe from the hair tip is 0.6mm;

[0044] (4) Set the badminton speed to 30r / min, and the dispensing speed to 2mm / s. During the continuous rotation of the shuttlecock, stick the glue on the tip of the hair. Stop sticking the glue every revolution to dry the glue. Stop sticking glue at 0.7mm;

[0045] (5) Put the glued badminton into 0.9Mpa nitrogen and let it stand for 20 minutes.

[0046] The viscose is composed ...

Embodiment 3

[0054] A technique for dipping hair tip glue for badminton processing, comprising the following steps:

[0055] (1) After the badminton is finished, check whether the feather tips are distributed equidistantly, and the qualified products that are equidistantly distributed enter the next process;

[0056] (2) Put the viscose into the heating body of the circular dispenser for heating;

[0057] (3) Put the badminton on the fixture of the circular dispensing machine, set the program to automatically adjust the height of the dispensing syringe, so that the height of the dispensing syringe from the hair tip is 0.7mm;

[0058] (4) Set the badminton speed to 30r / min, and the dispensing speed to 2mm / s. During the continuous rotation of the shuttlecock, stick the glue on the tip of the hair. Stop sticking the glue every revolution to dry the glue. Stop sticking glue at 0.8mm;

[0059] (5) Put the glued badminton into 1Mpa nitrogen and let it stand for 20 minutes.

[0060] The prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com