Outboard template construction method of post-pouring belt of outer wall of underground structure

A construction method and technology of external formwork, which are applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as unfavorable brick mold structure stability, bottom rotation crushing, and resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

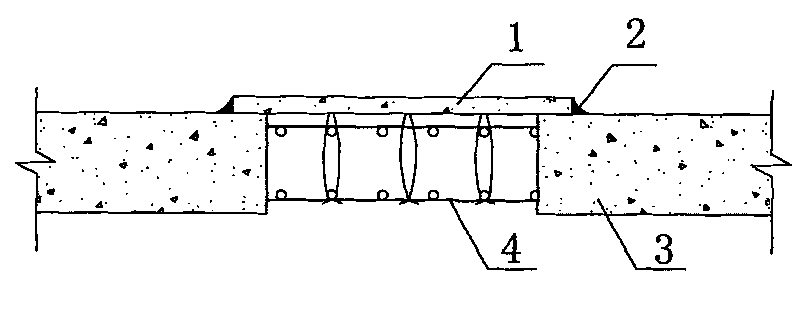

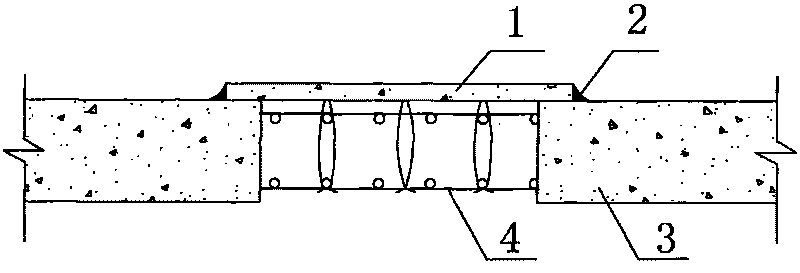

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] The construction method of the external formwork of the post-pouring belt of the exterior wall of the underground structure described in this embodiment is carried out according to the following steps:

[0016] a. Binding prefabricated slab steel bars according to the width of the post-casting belt: extract the corresponding type of steel bars from the steel bar waste generated on the construction site, and bind the steel bar skeleton according to the single-row two-way binding method. m or 1.2 m;

[0017] b. Binding and fixing prefabricated panel steel wires: After the reinforcement skeleton is bound, bind and fix the prefabricated panel steel wires at the intersection of horizontal and vertical steel bars. The length of the steel wires is 400-500mm, and the binding position of the steel wires is arranged in a plum blossom shape. This steel wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com