Ground coal seam gas extraction technology

A coal seam gas and ground technology, applied in the field of coal mine gas mining, can solve the problems of no further progress in ground gas drainage technology, large investment in gas control, etc., and achieve the effect of maximizing investment benefits, reducing pollution, and improving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

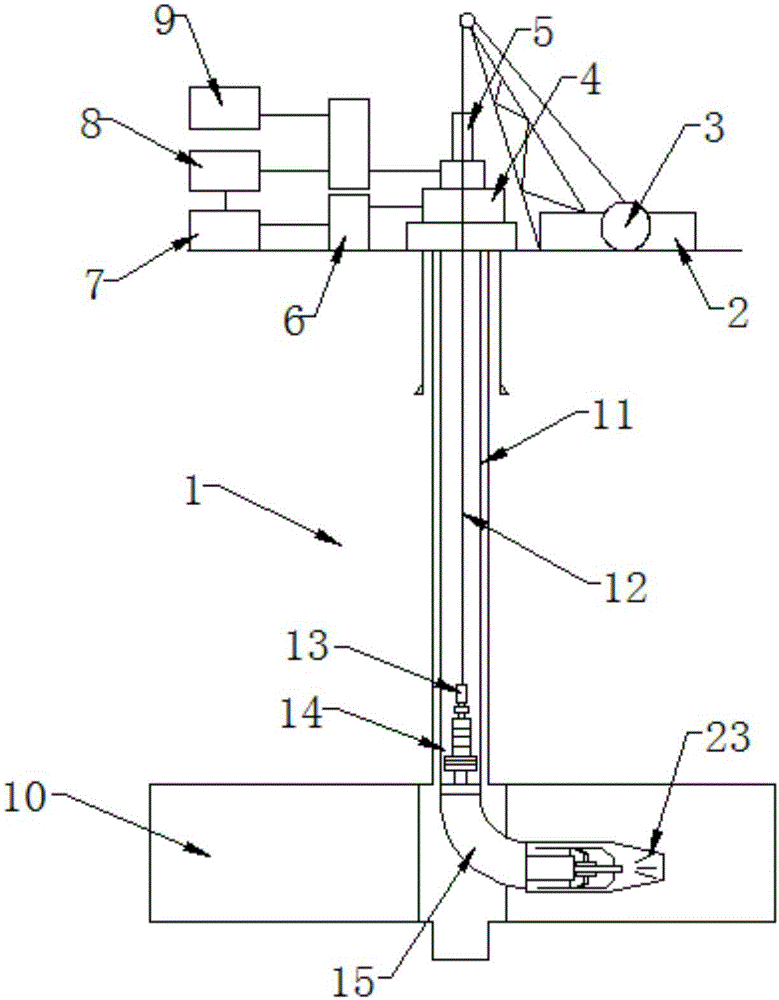

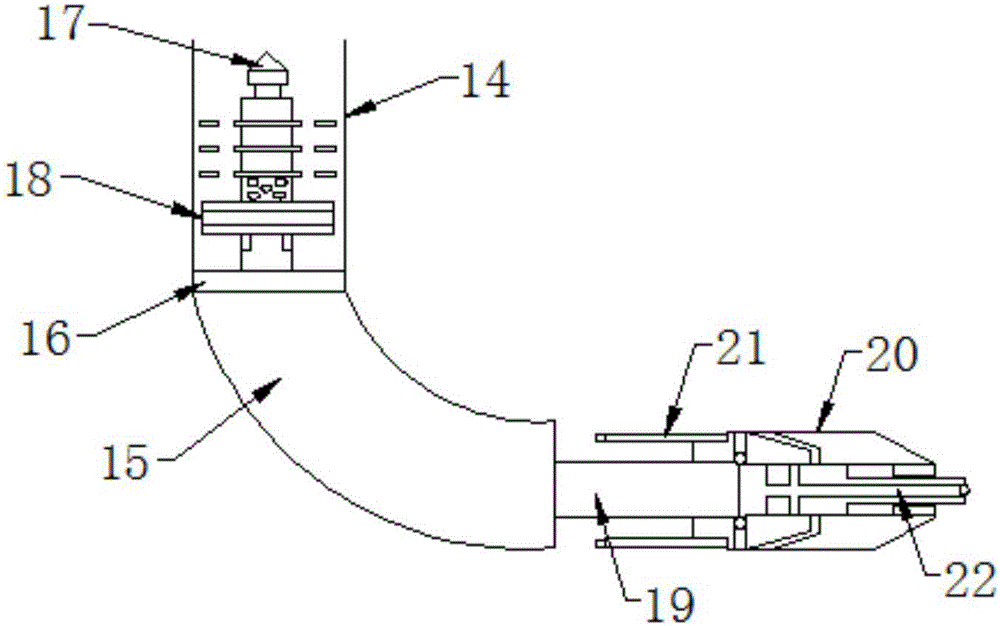

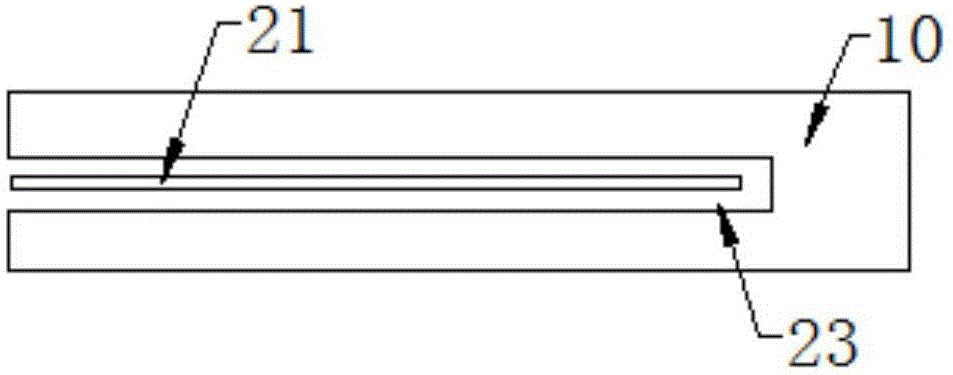

[0021] Such as Figure 1-6 As shown, a coal seam gas extraction technology of the present invention includes a main body 1, and the main body 1 includes a working vehicle 2, a working string tubing 11, a downhole directional guide tool 15, a nitrogen generator 25, nitrogen gas 26 and gas collection Pipeline 27, the working string oil pipe 11 is located under the working vehicle 2, and the working string oil pipe 11 is provided with a steel wire rope 12 and a supporting screen pipe follow-up drilling tool assembly 14, and the supporting screen pipe A fishing rope cap 13 is provided on the top of the follow-up drilling tool assembly 14, and the wire rope 12 is connected with the support screen follow-up drilling tool assembly 14 through the salvage rope cap 13, and the support screen follow-up drill A rope fishing head 17 is provided on the top of the drilling tool assembly 14, and the rope fishing head 17 is connected to the fishing rope cap 13, and a piston 18 is provided at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com