Construction method for high and cold region tunnel hole body water resistance

A technology of high-cold regions and construction methods, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of inconvenient installation of insulation boards, slow construction speed, etc., and achieve fast construction speed, easy construction, and good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

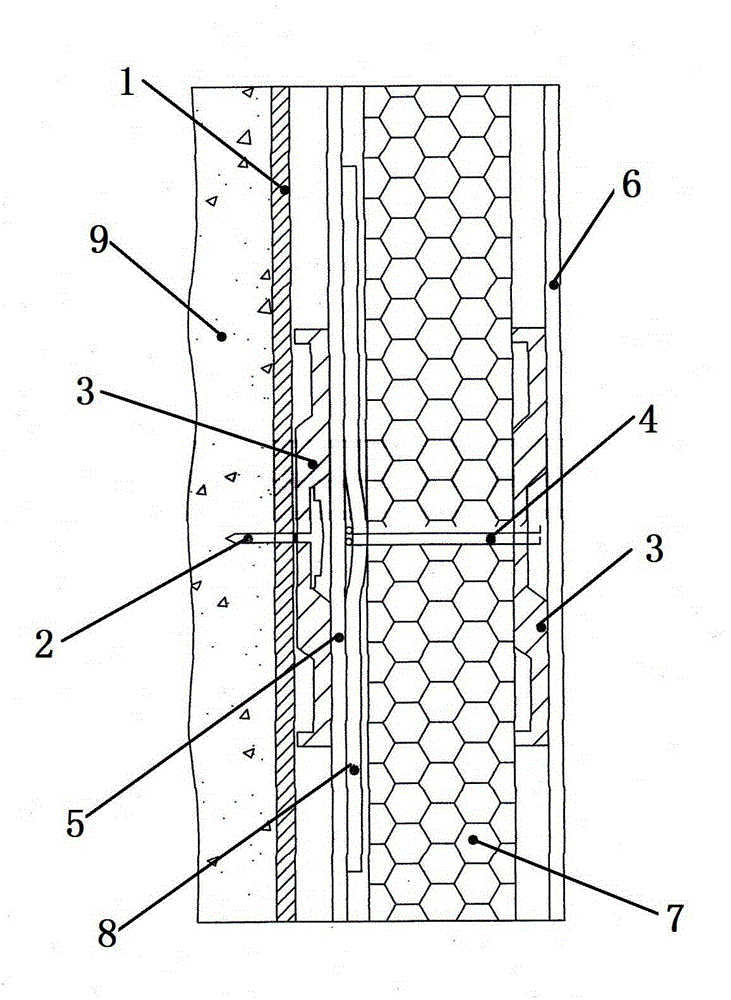

[0009] The non-woven fabric is laid on the surface of the sprayed concrete layer of the tunnel body, several hot-melt liners are arranged on the outer surface of the non-woven fabric, and the hot-melt liner and the non-woven fabric are fixed on the shotcrete layer by nailing. The above-mentioned hot-melt liners are arranged in a plum blossom shape, wherein the distance between adjacent heat-melt liners (horizontal and longitudinal distances) at the arch is 0.5m-0.8m, and the distance between adjacent heat-melt liners at the side walls (horizontal space and longitudinal spacing) is 0.8m-1.0m; the laying of non-woven fabrics should be moderately tight so that they can be tightly attached to the surface of the shotcrete layer.

[0010] Weld the inner waterproof board to the hot-melt liner fixed on the non-woven fabric with an electric fusion welder, use the leftover material of the waterproof board to make several suspenders with a width of 2 cm and a length of 8 cm, and press the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com