Manufacturing method of graded polarizing liquid crystal light valve

A liquid crystal light valve and gradient technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of low light transmittance and heavy weight of polarizers, which cannot meet the needs of drivers. Light valve lenses are light in weight, impact-resistant and high light transmittance High efficiency and other issues, to achieve the effect of clear vision and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

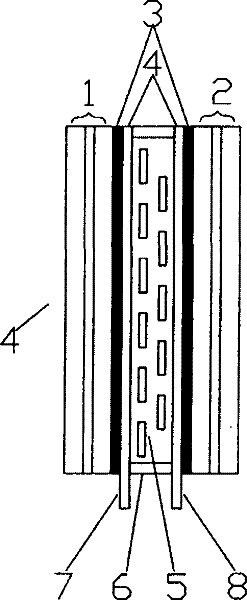

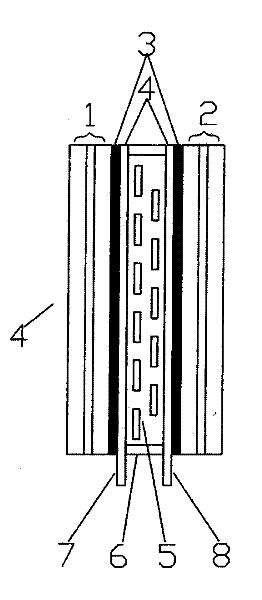

[0025] Depend on figure 1 As is well known, the gradient polarized liquid crystal light valve is composed of polarizers 1, 2, indium tin oxide conductive layer 3, alignment layer 4, TN type liquid crystal 5, edge sealant 6, and control electrodes 7, 8. The polarizers 1 and 2 are composed of two cellulose acetate sheets 2-1 with a gradient polarizing film 2-2 sandwiched between them, and the edge sealant 6 seals both ends of the TN type liquid crystal 5 .

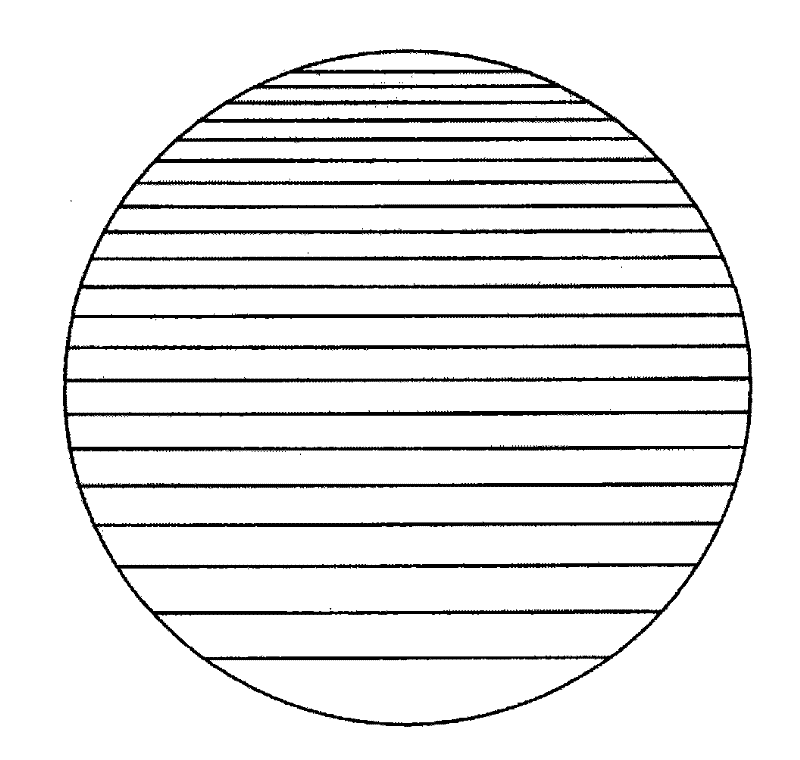

[0026] Depend on figure 2 It is a schematic diagram of the front view effect of the liquid crystal light valve in this embodiment. Apply a 2-3V 100Hz oscillating voltage to both ends of the gradient polarized liquid crystal light valve control electrodes 7 and 8, and the upper part of the light valve will turn dark black within 0.1 second, and the transparency will gradually increase as the degree of polarization decreases downward until the lower end of the light valve becomes transparent. After the power is cut off, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com