Direct-type LED backlight color uniformity correction system and direct-type LED backlight color uniformity correction method

An LED backlight and color uniformity technology, which is applied in the field of direct-lit LED backlight color uniformity correction systems, can solve problems such as high cost and complex system, and achieve the effects of low cost, simple implementation method and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

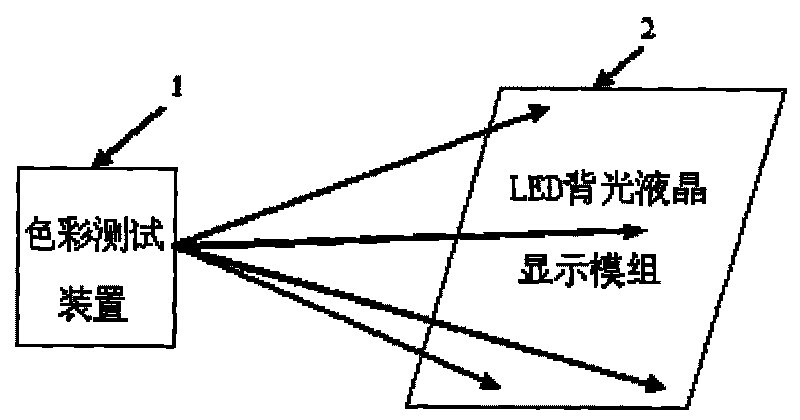

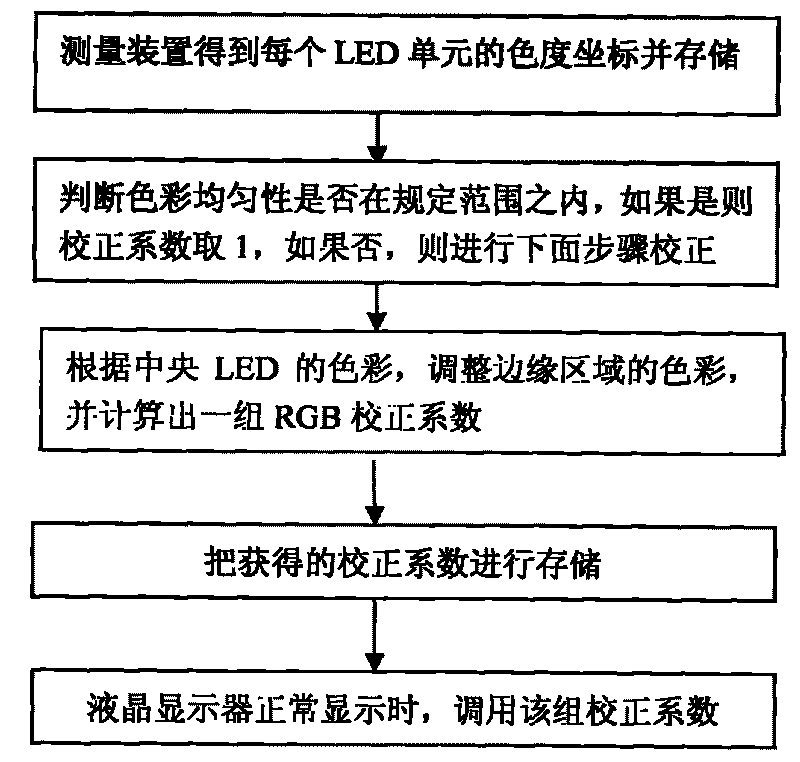

[0018] Such as figure 1 As shown, the system of the present invention includes a color measurement device 1 and an LED backlight liquid crystal display module 2 optically connected to it. Wherein, the LED backlight liquid crystal display module 2 includes an LED backlight unit, an LED backlight drive control unit for driving the LED backlight unit, and a liquid crystal display; The color data of the LED backlight liquid crystal display module 2 is obtained and stored, and the stored data is analyzed and processed to obtain a correction coefficient.

[0019] When the liquid crystal display is working normally, each LED backlight unit is multiplied by the correction coefficient on the basis of the statistical data of the original algorithm to obtain the actual data of the backlight. In order to achieve the consistency of backlight color.

[0020] The color measurement device 1 of the present invention adopts a luminance and chromaticity tester, and the liquid crystal display o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com