Method for preparing gradient polymer porosity broadband antireflection film

A technology of gradient porosity and high polymer, which is applied in the field of preparation of high polymer gradient porosity broadband anti-reflection film, to achieve the effect of high transmission and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

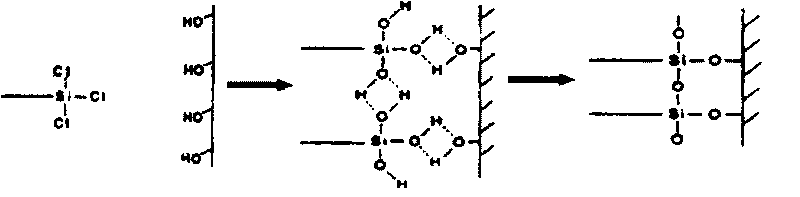

[0017] (1) OTS modification of glass.

[0018] Soak the cleaned glass in 0.1% OTS n-hexane solution by volume fraction for 5 minutes, then clean the soaked glass with pure n-hexane, and blow dry the glass surface.

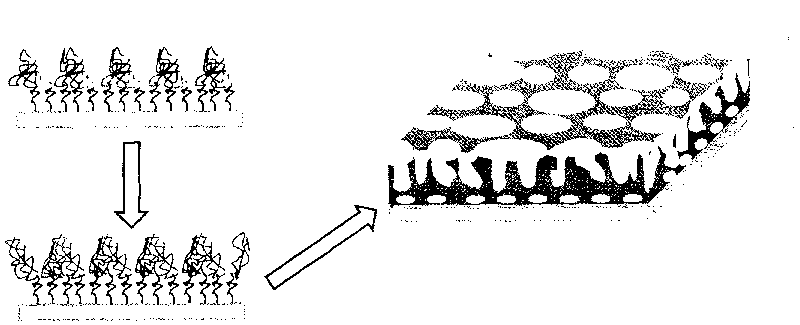

[0019] (2) tetrahydrofuran and toluene are formed into a mixed solvent, and the volume percentage of tetrahydrofuran in the mixed solvent is 10%, and the high polymer is added in the mixed solvent to prepare a solution with a total concentration of 27 mg / ml; the high polymer is PS- b-PMMA and a blend of PMMA, wherein the homopolymer PMMA accounts for 20% of the total mass of the high polymer.

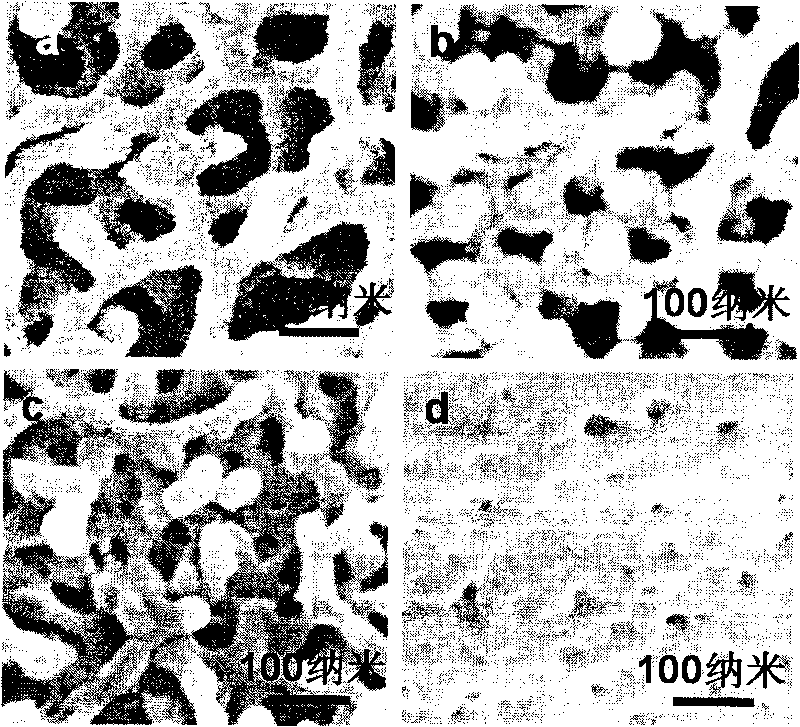

[0020] (3) Spin-coat the solution prepared in step (2) on the glass prepared in step (1) to form a high polymer film on the glass surface. The polymer film was irradiated with ultraviolet light for 3 hours to degrade the PMMA therein, then soaked in acetic acid for 1 hour, and finally the glass with the polymer film was cleaned with deionized water, and the glass surface wa...

Embodiment 2

[0022] (1) OTS modification of ITO glass.

[0023] Soak the cleaned ITO glass in 0.05% OTS n-hexane solution for 10 minutes, then clean the impregnated ITO glass with pure n-hexane, and dry the ITO glass surface.

[0024] (2) tetrahydrofuran and toluene are formed into a mixed solvent, and the volume percentage of tetrahydrofuran in the mixed solvent is 2%, and the high polymer is added into the mixed solvent to prepare a solution with a total concentration of 32 mg / ml; the high polymer PS-b -PMMA and a blend of PMMA, wherein the homopolymer PMMA accounts for 5% of the total mass of the high polymer.

[0025] (3) Spin-coat the solution prepared in step (2) on the ITO glass prepared in step (1) to form a polymer film on the surface of the ITO glass. The polymer film was irradiated with ultraviolet light for 2 hours to degrade the PMMA in it, then soaked in acetic acid for 0.5 hour, and finally the ITO glass with the polymer film was cleaned with deionized water, and the surfac...

Embodiment 3

[0027] (1) OTS modification of glass.

[0028] Soak the cleaned glass in 0.15% OTS n-hexane solution by volume fraction for 3 minutes, then clean the soaked glass with pure n-hexane, and blow dry the glass surface.

[0029] (2) tetrahydrofuran and toluene are used to form a mixed solvent, and the volume percentage of tetrahydrofuran in the mixed solvent is 20%, and the high polymer is added in the mixed solvent to prepare a solution with a total concentration of 36 mg / ml; the high polymer is PS- b-PMMA and a blend of PMMA, wherein the homopolymer PMMA accounts for 10% of the total mass of the high polymer.

[0030] (3) Spin-coat the solution prepared in step (2) on the glass prepared in step (1) to form a high polymer film on the glass surface. The polymer film was irradiated with ultraviolet light for 3 hours to degrade the PMMA therein, then soaked in acetic acid for 1.5 hours, and finally the glass with the polymer film was cleaned with deionized water, and the glass surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com