Low-carbon active ligand and low-carbon slag powder cementitious material

A technology of slag powder and cementitious materials, which is applied in the field of building materials, can solve problems such as the depletion of mineral resources, the shortage of industrial energy, and the deterioration of the atmospheric environment, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Step 1: Synthesis of low-carbon active ligands

[0011] First, grind 1 kg of bauxite, 8 kg of gypsum, and 3 kg of garnet in a small mill to make the specific surface reach 250-350m 2 After / g is the low-carbon positive ligand;

[0012] Grind 6kg of Glauber's salt and 1kg of fluorite in a mill again to make the specific surface reach 250-350m 2 After / g is the low carbon negative ligand;

[0013] Finally, 12 kg of low-carbon positive ligands and 7 kg of low-carbon negative ligands are added to the mill to make the specific surface reach 420-450m 2 / g to obtain low-carbon active ligands.

[0014] The second step: preparation of slag micropowder cementitious material:

[0015] Take 5 kg of the above-mentioned low-carbon active ligand and grind it with 95 kg of slag to make the specific surface reach 420-450m 2 / g and fully homogenized to obtain low-carbon slag powder {32.5 grade} cementitious material.

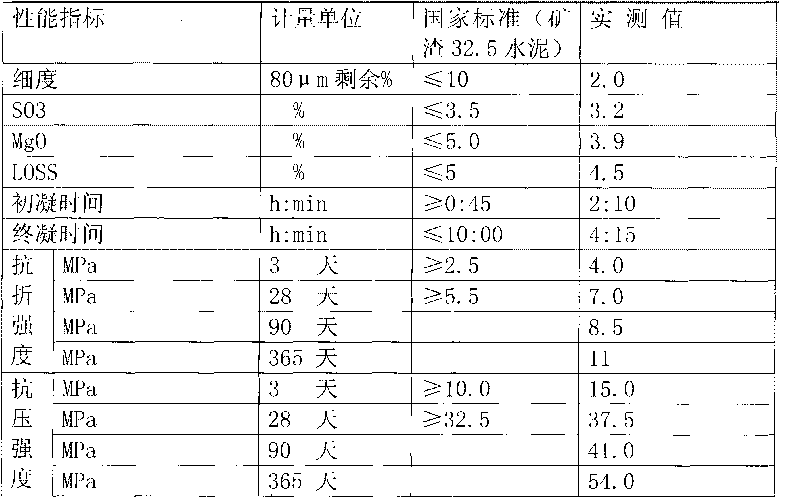

[0016] Experimental test:

[0017] Measure its various perform...

Embodiment 2

[0022] Step 1: Synthesis of low-carbon active ligands

[0023] 1. Grind 1 kg of bauxite, 8 kg of gypsum, and 3 kg of garnet in a mill to make the specific surface reach 250-350m 2 / g, to obtain low carbon type positive ligand;

[0024] 2. Grind 6 kg of Glauber's salt and 1 kg of fluorite in a mill to make the specific surface reach 250-350m 2 / g, to obtain low carbon type negative ligand;

[0025] 3. Add 12 kg of low-carbon positive ligands and 7 kg of low-carbon negative ligands into the mill to make the specific surface reach 420-450m 2 / g to obtain low-carbon active ligands.

[0026] The second step: preparation of slag micropowder cementitious material:

[0027] Take 7 kg of the above-mentioned low-carbon active ligand and grind it with 93 kg of slag to make the specific surface reach 420-450 m 2 / g and fully homogenized to obtain low-carbon slag powder {42.5 grade} cementitious material

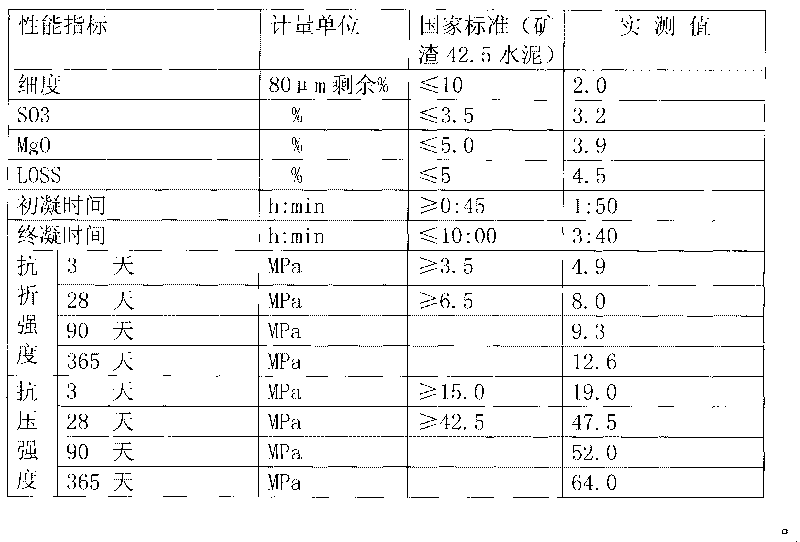

[0028] Experimental test:

[0029] Measure its various performance indicators...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com