Method for monitoring suspended solid SS in sludge water of water treatment plant

A technology for suspended solids concentration and sludge discharge, which is applied in particle suspension analysis, suspension and porous material analysis, and measuring devices. It can solve problems such as adjustment based on experience, unchanged operation management, and long measurement time, and achieve high operating costs. Inexpensive, highly economically feasible, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

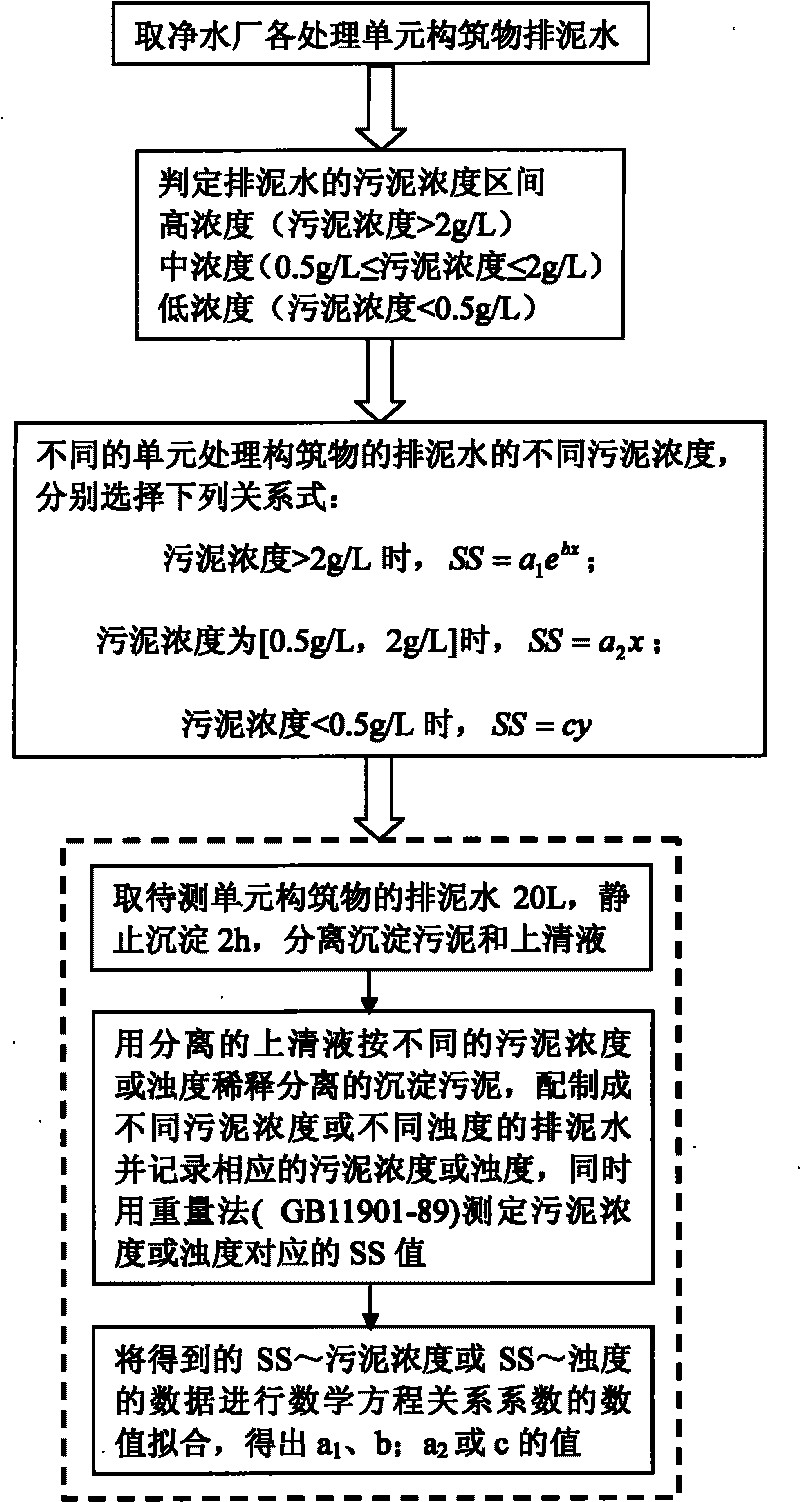

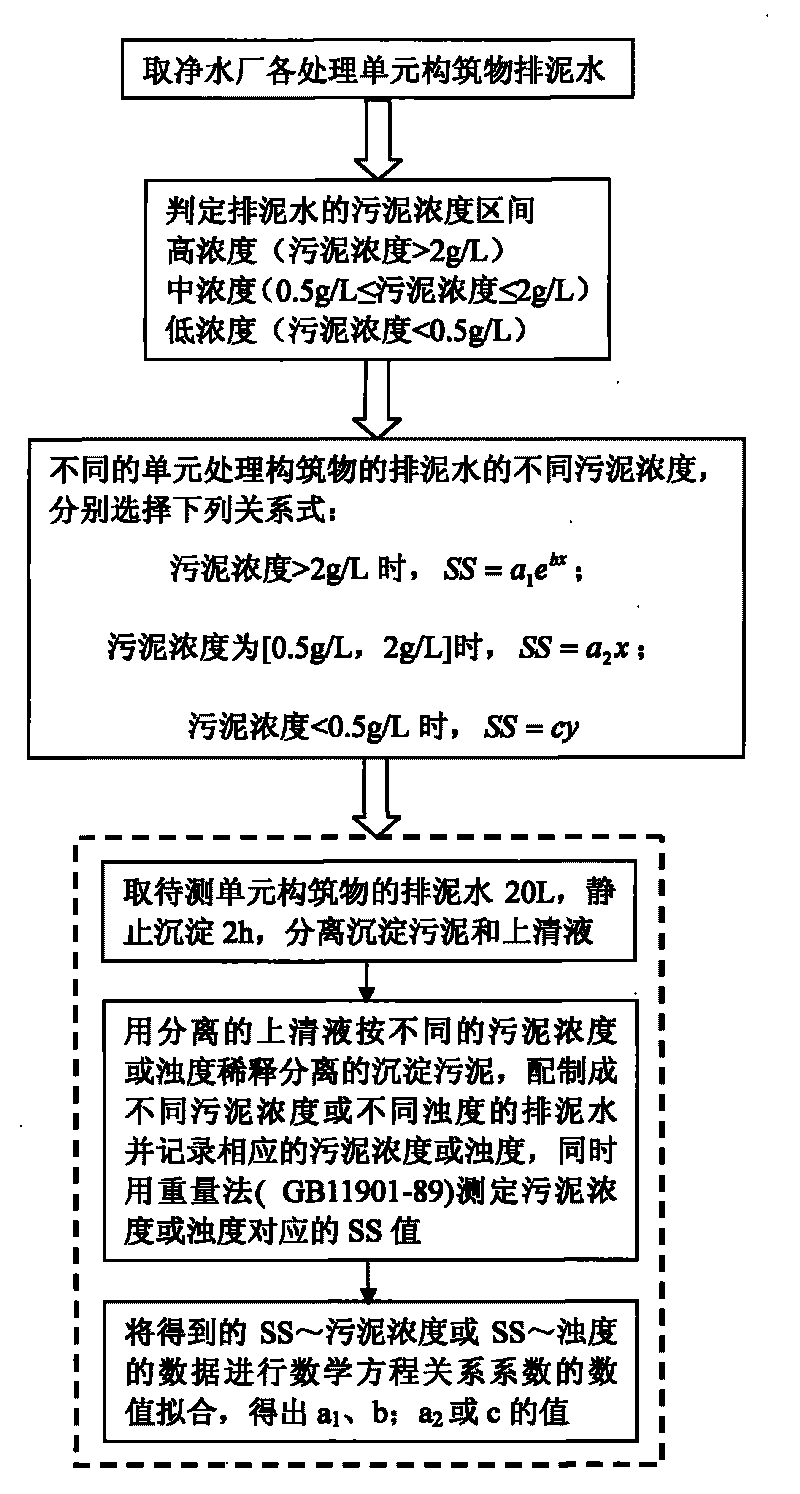

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0027] Monitoring location: a city water plant in Nanjing

[0028] Water treatment process of water plant: raw water from the Yangtze River → clarification → filtration → disinfection → factory water

[0029] Sludge water from unit treatment structures comes from: clarifier tank, V-shaped filter tank

[0030] A. Determination of the sludge concentration range of the SS monitoring method for the suspended solids concentration of the sludge water in the water purification plant:

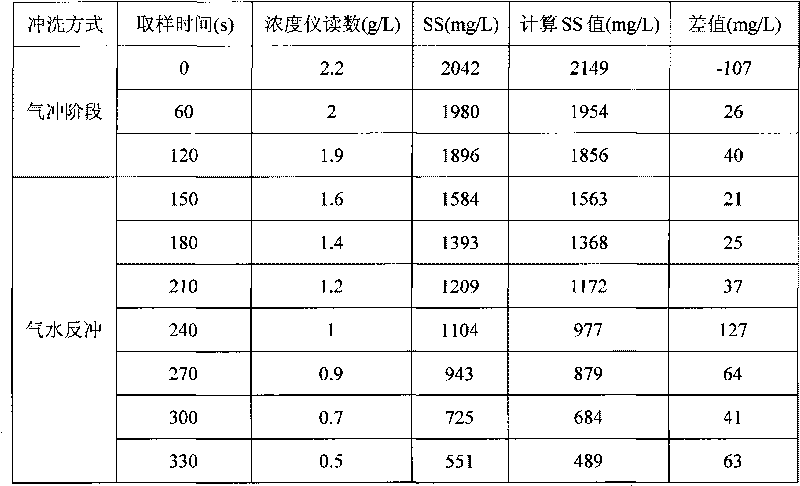

[0031] Take a small amount of sludge discharge water from the clarifier and V-shaped filter, stir to keep the water sample uniform, and measure the sludge concentration with a portable sludge concentration meter. The sludge concentration in the clarifier is about 16g / L > 2g / L is a high concentration range, The sludge concentration of the V-type filter air flushing and air wate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap