Method for preparing aluminate green phosphor with low content of terbium

A technology of aluminate and content, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of reduced luminous performance of phosphor powder, increased cost of fluorescent lamps, and high price of rare earth terbium oxide, so as to reduce usage, reduce cost, The effect of improving cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

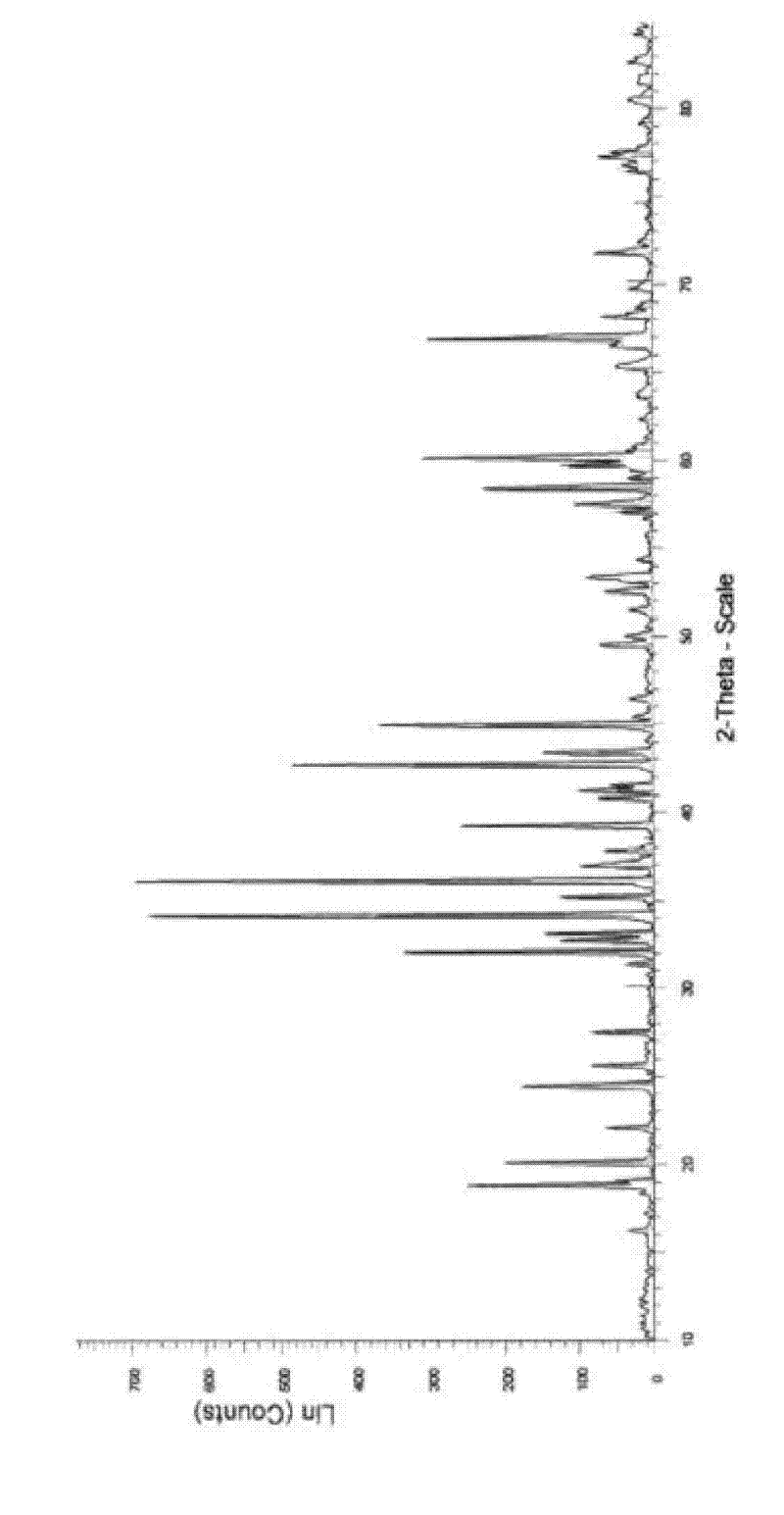

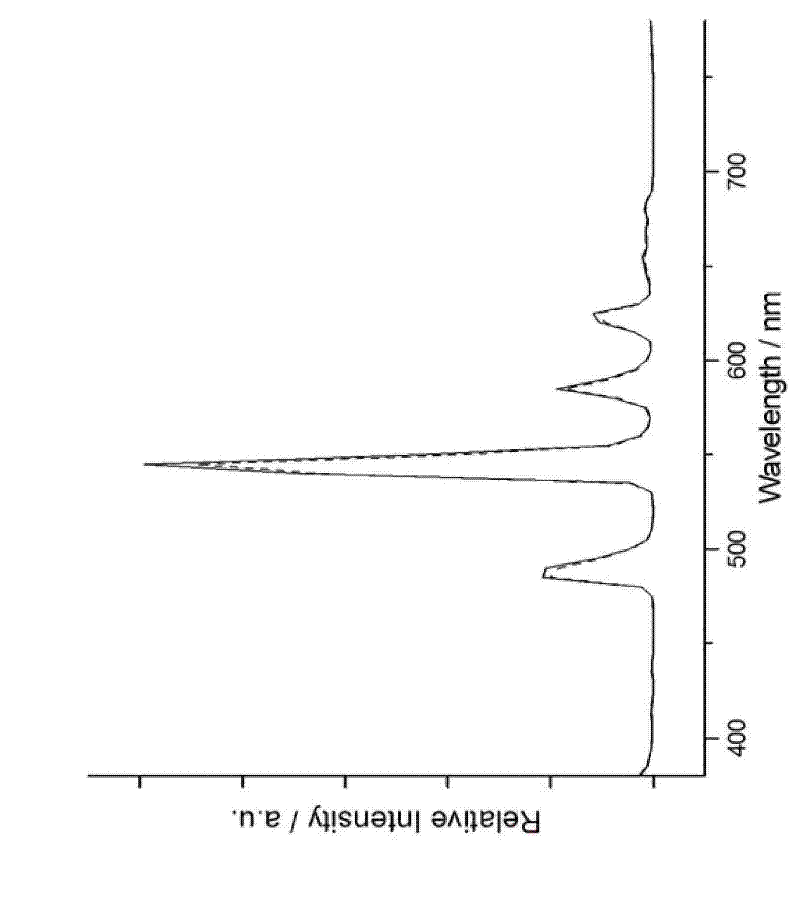

Image

Examples

Embodiment 1

[0016] Ce 0.80 MgAl 11 o 19 :Tb 0.20

[0017] 1) Take 3.581g of cerium oxide, 1.049g of magnesium oxide, 14.582g of aluminum oxide, and 0.096g of magnesium fluoride, grind them in a mortar for one hour, put them in a crucible, and calcinate them in a muffle furnace at 1600°C for 7 hours Afterwards, cool naturally, take out and grind for half an hour to obtain powder A without terbium;

[0018] 2) Take 0.972g of terbium oxide, dissolve it in hydrochloric acid, and make it into a 0.05mol / L Tb ion solution, pour the powder A into the Tb ion solution, and slowly add 2mol / L ammonia water under stirring to adjust the pH Adjust the value to 8.0 to make Tb ions precipitate on the surface of powder A;

[0019] 3) Then continue to stir for 30 minutes, and then stand still for 30 minutes to completely precipitate Tb ions, filter and dry to obtain loose powder B.

[0020] 4) put the powder into the crucible, under N 2 95% / H 2 After reacting at 1450° C. for 3 hours in a 5% reducing...

Embodiment 2

[0022] Ce 0.78 MgAl 11 o 19 :Tb 0.22

[0023] 1) Take 3.490g of cerium oxide, 1.048g of magnesia, 14.575g of aluminum oxide, and 0.191g of boric acid, grind them in a mortar for one hour, put them in a crucible, and calcinate them in a muffle furnace at 1500°C for 6 hours, Cool naturally, take it out and grind it for half an hour to obtain terbium-free powder A;

[0024] 2) Take 1.069g of terbium oxide, dissolve it in hydrochloric acid, and make a solution of 0.05mol / L, pour the powder A into the Tb ion solution, add 25ml of 1mol / L urea solution under stirring, and then dissolve the solution Heat to 90°C to precipitate Tb ions on the surface of powder A;

[0025] 3) Constant temperature for 2 hours, then continue to stir for 30 minutes, and then let it stand for 30 minutes to completely precipitate Tb ions, filter and dry to obtain loose powder B;

[0026] 4) put the powder B into the crucible, 2 90% / H 2 After reacting at 1300° C. for 4 hours in a 10% reducing atmosphe...

Embodiment 3

[0028] Ce 0.75 MgAl 11 o 19 :Tb 0.25

[0029] 1) Take 3.353g of cerium oxide, 1.047g of magnesium oxide, 14.565g of aluminum oxide, and 0.569g of aluminum fluoride, grind them in a mortar for one hour, put them into a crucible, and calcinate them in a muffle furnace at 1450°C for 5 hours Afterwards, cool naturally, take it out and grind for half an hour to obtain powder A without terbium.

[0030] 2) Take 1.214g of terbium oxide, dissolve it in nitric acid, and make it into a 0.20mol / L Tb ion solution, pour the powder A into the Tb ion solution, and slowly add 10mol / L of ammonia water under stirring to adjust the pH Adjust the value to 9.5 to make Tb ions precipitate on the surface of powder A;

[0031] 3) Continue to stir for 60 minutes, and then let stand for 45 minutes to completely precipitate Tb ions, filter and dry to obtain loose powder B;

[0032] 4) put the powder into the crucible, under N 2 95% / H 2 After reacting at 1525° C. for 5 hours in a 5% reducing atmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com