Wheel diameter jumpiness and run-out tolerance detection method

A poor detection and wheel technology, which is applied in the field of mechanical product detection, can solve the problems that the positioning reference cannot be reasonably unified, lack of objectivity, and large differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

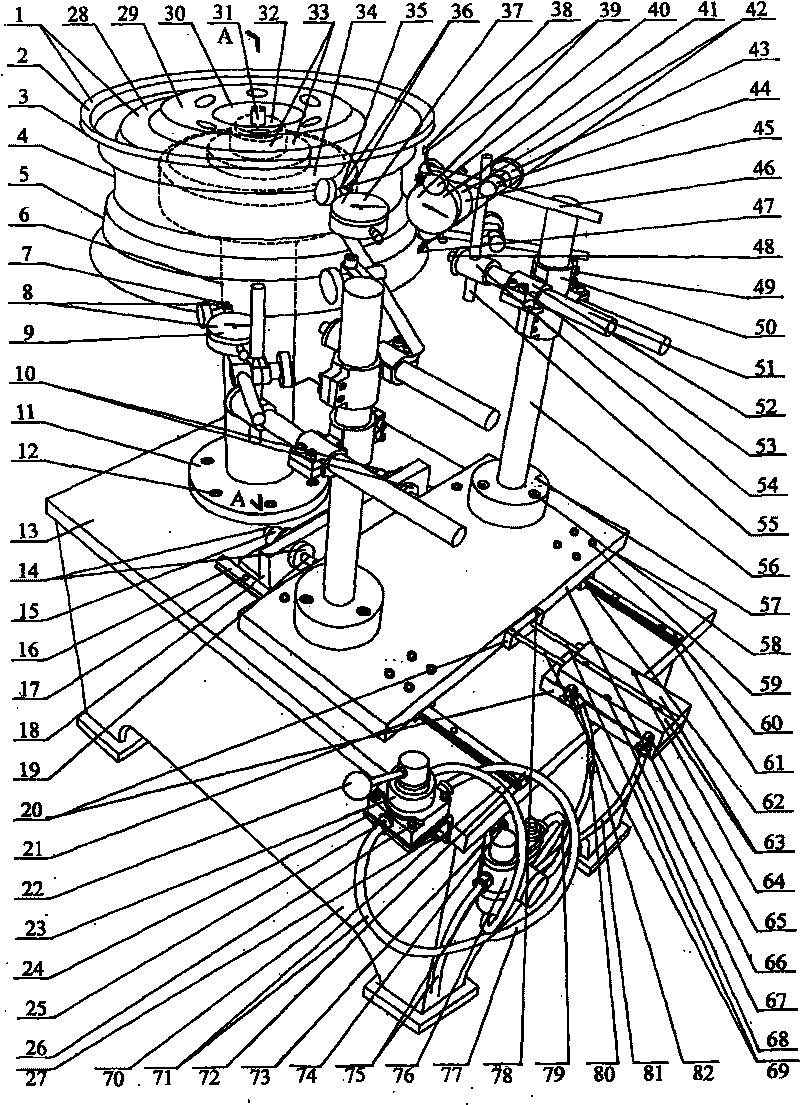

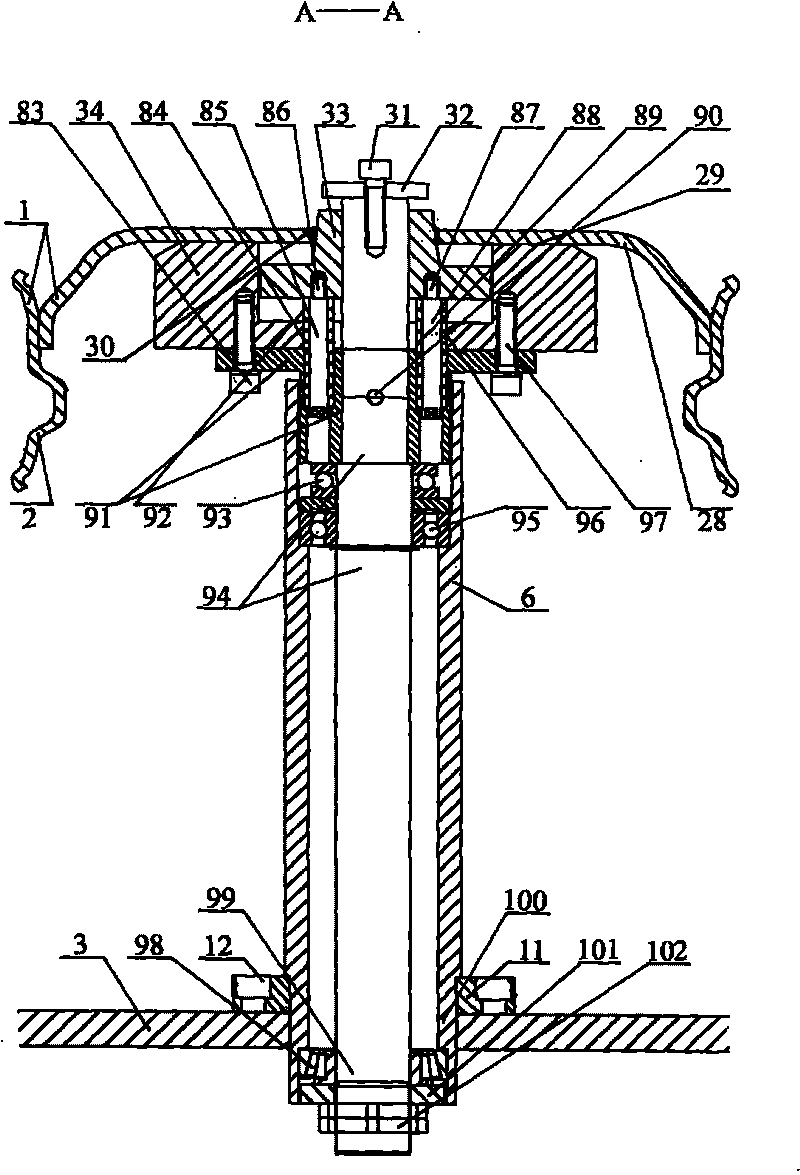

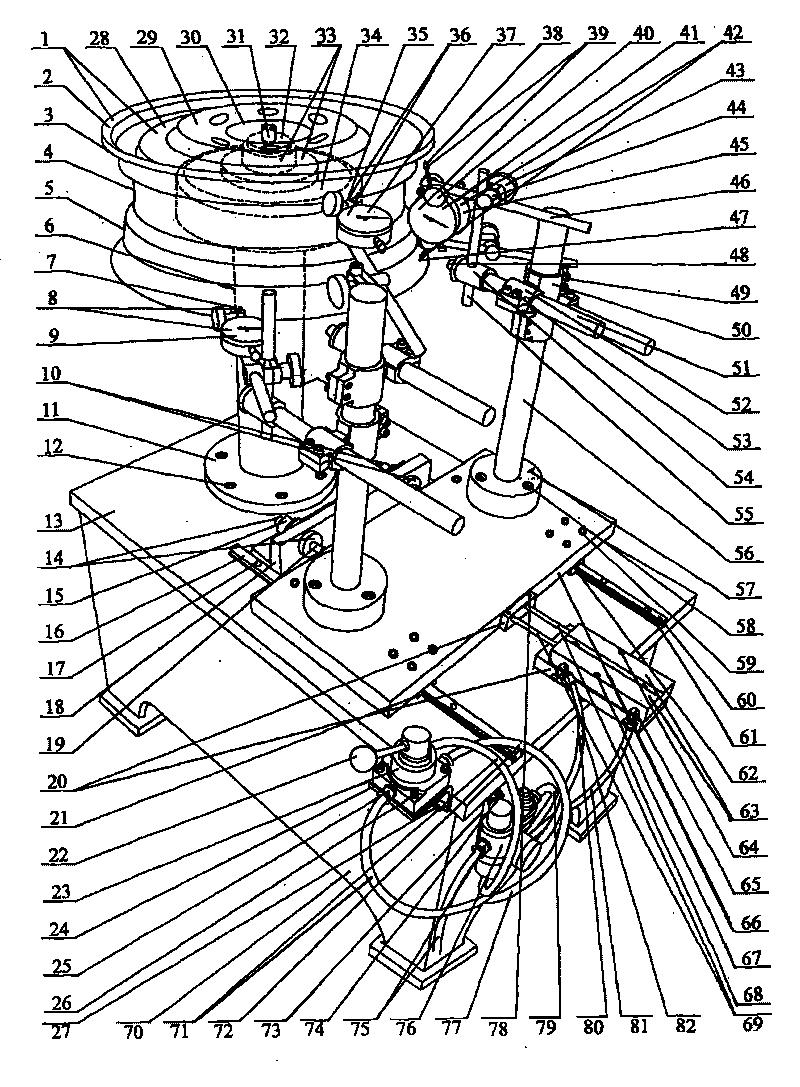

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] Wheel radial runout detection method, such as figure 1 and figure 2 As shown, the scheme is the detection process of wheel run-out and run-out, which includes the following specific operation steps for detecting wheel run-out and run-out with a wheel run-out and run-out detection machine and divided into three operation stages:

[0014] The pre-use inspection and preparation stage of testing equipment,

[0015] The first step is to check the ventilation of the air cylinder 63 and the air valves 23 and 76. Through the air guide tube 75 and the joint 75, connect the air valves 23 and 76 and the air cylinder 63 to the air pressure source outside the machine, and turn the air valve 23 up and down in turn. The handle 22 to the cylinder 63 is kept in the positive working state and the reverse working state in turn, so that the moving platen 66 will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com