Fiber grating monitoring system for power transmission line

A fiber grating and monitoring system technology, applied in the field of electric power, can solve the problems of transmission speed and image quality limitations, difficulty in guaranteeing the stability and service life of resistance strain gauges, and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

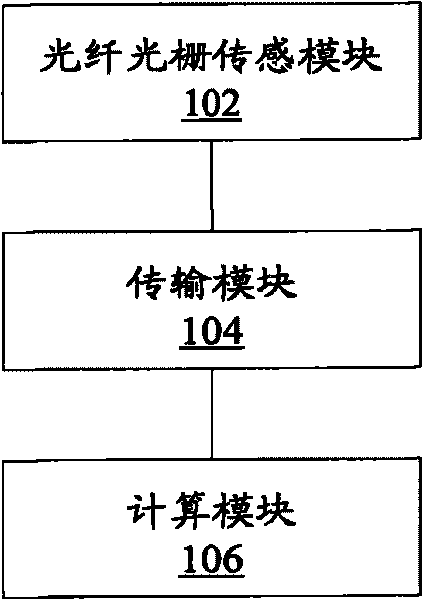

[0019] figure 1 A schematic diagram of a fiber grating monitoring system for power transmission lines according to an embodiment of the present invention is shown, including: a fiber grating sensing module 102, a transmission module 104 and a calculation module 106, wherein

[0020] The fiber grating sensing module 102 is configured to receive the first optical signal transmitted by the transmission module 104, and transmit the second optical signal reflected by the first optical signal to the calculation module 106 through the transmission module 104;

[0021] a transmission module 104, configured to transmit the first optical signal and the second optical signal;

[0022] The calculation module 106 is configured to obtain the tension and inclination angle borne by the transmission line according to the change of the center wavelen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com