Anti-scalding pot lid handle

A pot lid and hand ring technology, which is applied to the lids of cooking utensils and other directions, can solve the problems of heat insulation, low heat dissipation, scalding people's hands by the handle of the pot lids, and scalding people's hands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

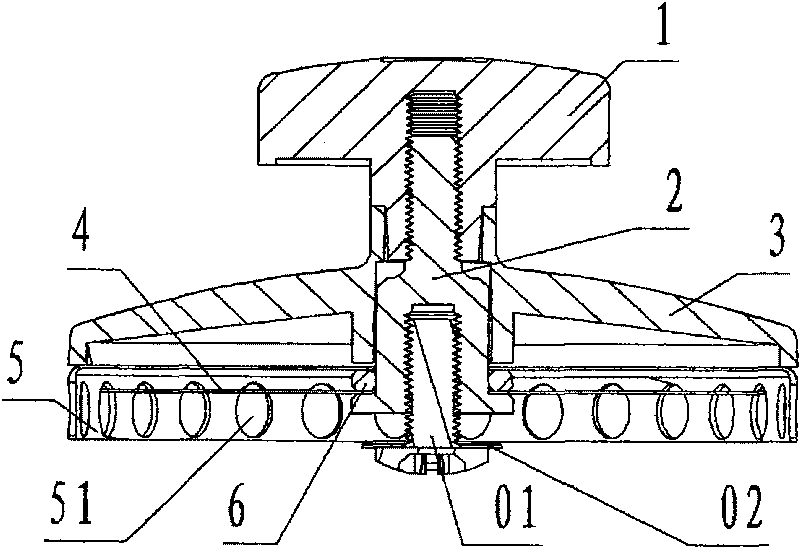

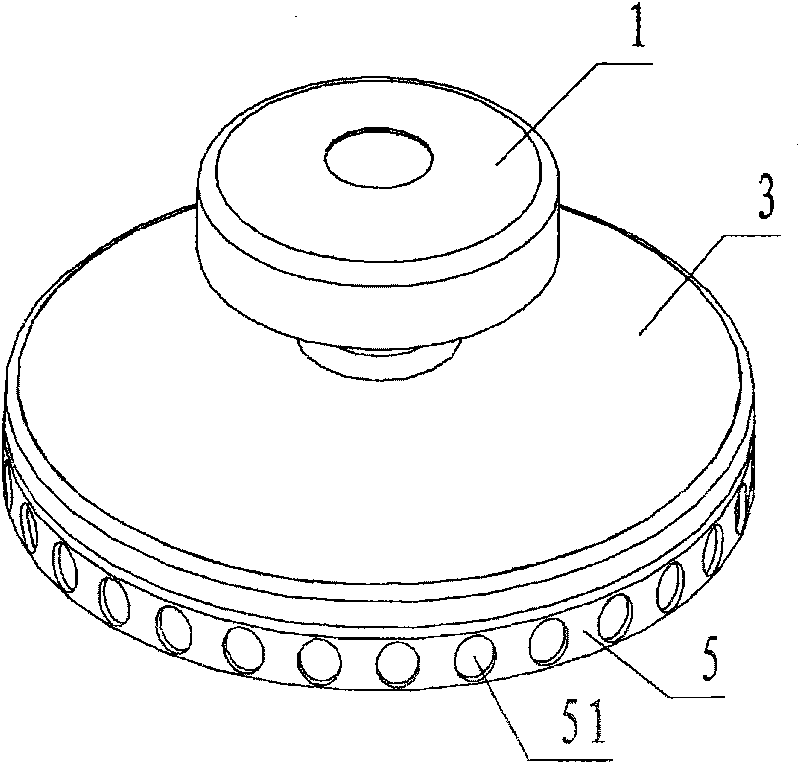

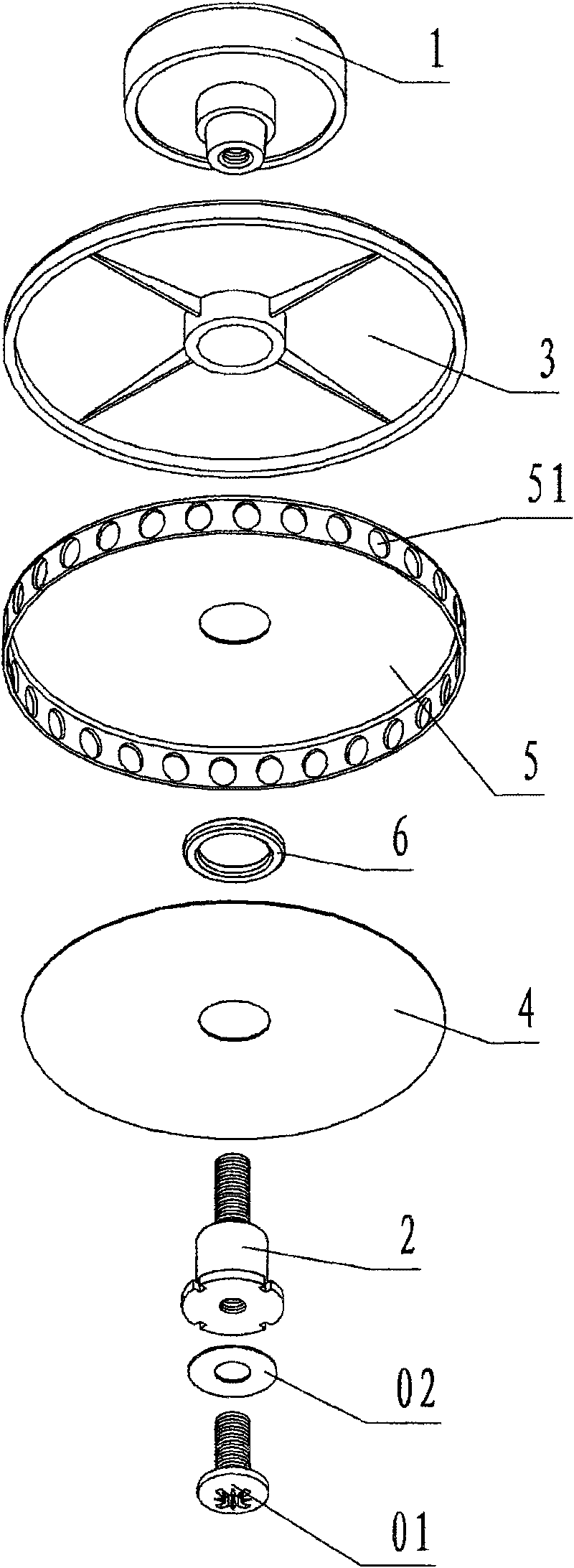

[0017] refer to Figure 1 ~ Figure 4 , a kind of anti-scalding pot lid handle of the present invention, comprises handle cap 1, heat-insulating serial screw core 2, heat-insulating hand ring 3, reflecting fin 4, heat-dissipating supporting ring 5, heat-insulating gasket 6, insulation Heat and cap 7, wherein: the handle cap 1 is a coaxial, upper, lower, and small three-step cylinder made of heat-resistant plastic, shaped like an umbrella-shaped mushroom-shaped handle; the small step at the lower end of the handle cap The center of the end face of the cylinder is provided with an internally threaded blind hole; the heat-insulating serial screw core 2 is a three-stage stepped cylinder made of heat-resistant plastic with a small upper part, a medium middle part, and a larger lower part of the coaxial line. The upper small step cylinder of the heat-insulating series screw core is provided with an external thread, and the external thread cooperates with the internal thread blind hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com