Method for modifying inorganic membrane by nano metal oxide

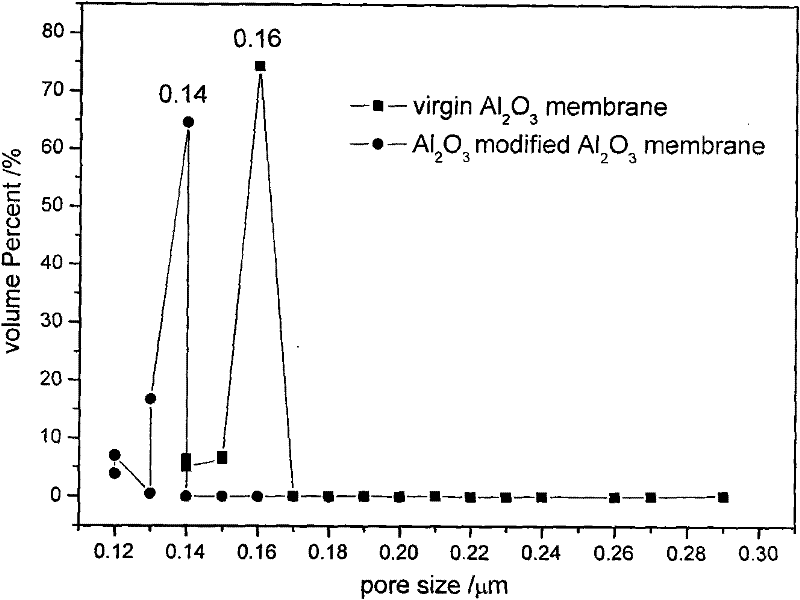

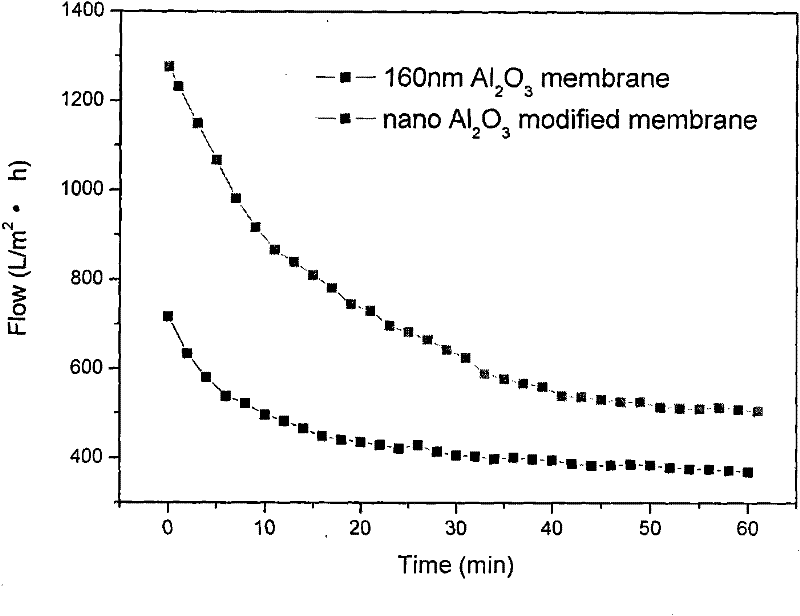

A nano-metal and inorganic membrane technology, applied in the field of inorganic membrane manufacturing, can solve the problems of easy blockage or reduction of membrane pores, reduced membrane permeation flux, uncontrollable particle size of sediment particles, etc. The effect of improving hydrophilicity and improving pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

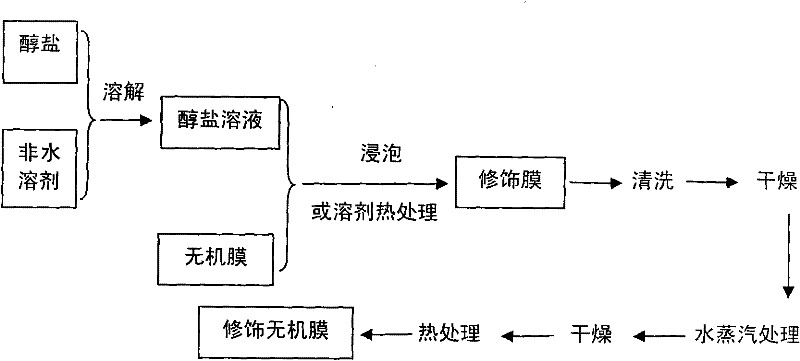

[0031] Dissolve 2g of P123 in 500ml of xylene, then add 10g of aluminum isopropoxide to the above solution under vigorous stirring, continue stirring for 30min after clarification, and immerse the alumina microfiltration membrane (average pore size of 0.16μm) in the The resulting solution was sealed and stored at 25°C for 4 hours. Take out the alumina microfiltration membrane, and wash the microfiltration membrane with xylene for 3 times under ventilated conditions. Also dry the microfiltration membrane under ventilated conditions until there is no xylene odor. The tap water is heated, and the opening of the water container is greater than the length of the microfiltration membrane tube. Control the heating rate to keep the water slightly boiling, place the microfiltration membrane tube at 15 cm above the water surface, and process for 2 hours. The alumina microfiltration membrane after the hydrolysis treatment was placed in a 100°C oven for drying for 4 hours, and then the ...

Embodiment 2

[0034] The other implementation process is the same as that of Embodiment 1, and 5 g of aluminum isopropoxide is added under vigorous stirring conditions.

Embodiment 3

[0036] Dissolve 2g of P123 in 500ml of xylene, then add 10g of aluminum isopropoxide to the above solution under vigorous stirring, continue stirring for 30min after clarification, and immerse the alumina microfiltration membrane (average pore size of 0.16μm) in the in the resulting solution. The aluminum oxide microfiltration membrane and the aluminum isopropoxide xylene solution were simultaneously transferred into a reaction kettle with a polytetrafluoroethylene liner, sealed, and subjected to solvent heat treatment at 120° C. for 2 hours. Take out the alumina microfiltration membrane, and wash the microfiltration membrane with xylene for 3 times under ventilated conditions. Also dry the microfiltration membrane under ventilated conditions until there is no xylene odor. The tap water is heated, and the opening of the water container is greater than the length of the microfiltration membrane tube. Control the heating rate to keep the water slightly boiling, place the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com