Integrally forming mould of composite propeller and manufacture method thereof

A composite material and integral molding technology, which is applied in household appliances, other household appliances, household components, etc., can solve problems such as propeller shaft vibration, propeller blades are prone to fatigue damage, and connection is difficult to achieve matching, so as to achieve positioning balance and meet strength The design and use requirements, the effect of precise size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

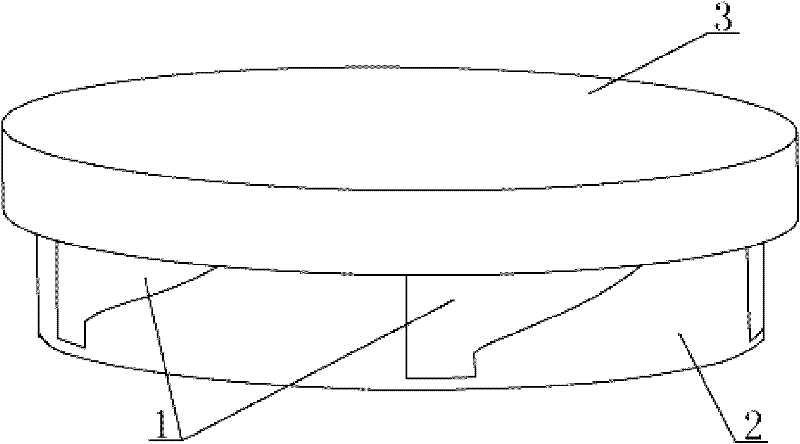

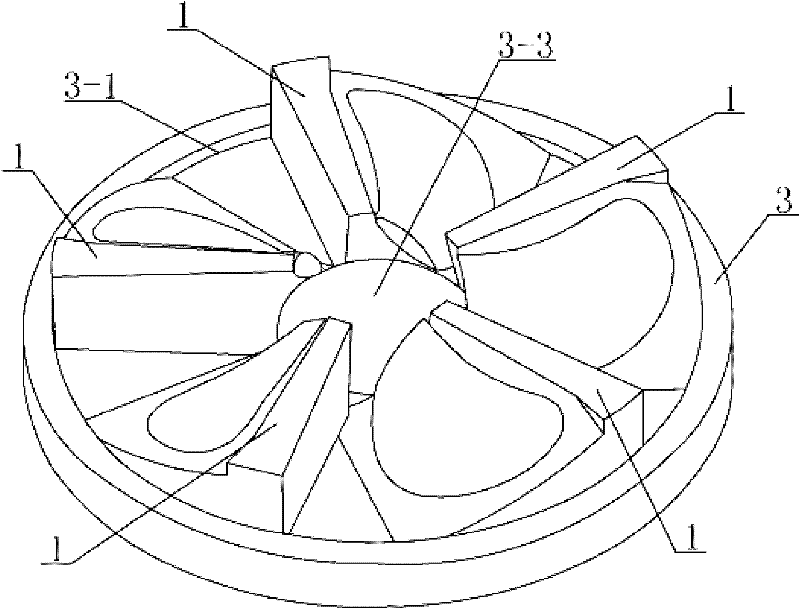

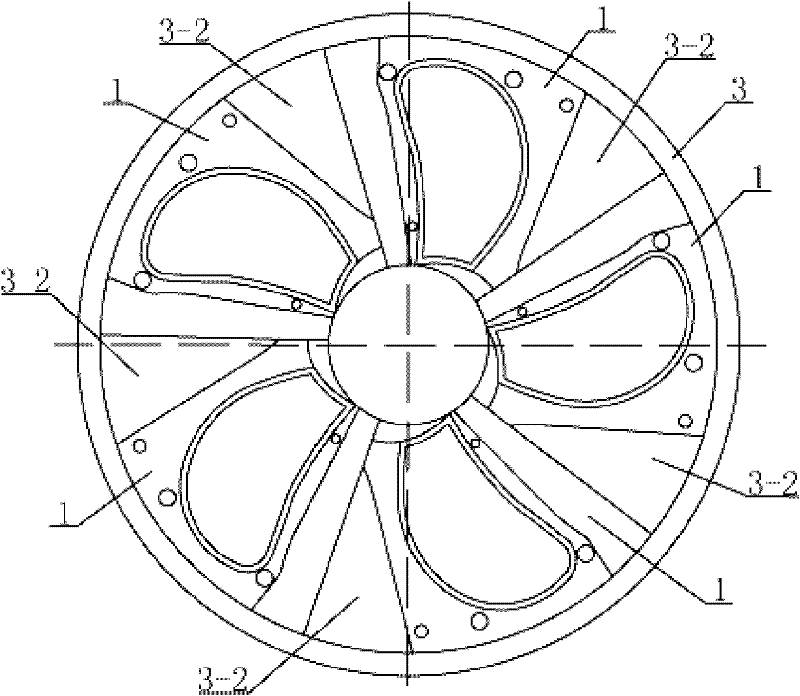

[0008] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, this embodiment is made up of at least three upper modules 1, lower mold 2 and cover plate 3, the lower end surface of cover plate 3 is provided with annular groove 3-1 along the circumference, and the inner top end surface of annular groove 3-1 At least three module slots 3-1-1 are evenly distributed on the top, the area between each module slot 3-1-1 is a positioning block 3-2, and the center of the lower end surface of the cover plate 3 is provided with a hub positioning flange 3 -3, the peripheral shape of each upper module 1 coincides with the peripheral shape of the module groove 3-1-1, and the upper mold parting surface 1 is sequentially provided on the lower end surface of each upper module 1 along the arc-shaped length direction -1 and sealing boss 1-2, upper mold parting surface 1-1 is provided with upper mold blade cavity 1-1-1, the top surface of upper mold blade cavity...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 The present embodiment is described. The upper module 1 , the cover plate 3 and the lower mold 2 of the present embodiment are all made of LY12 aluminum alloy. LY12 has good strength and compact structure, excellent processing and process performance, and is very suitable for processing components with complex surfaces such as propellers. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 6 ~ Figure 8 Describe this embodiment, this embodiment is realized by the following steps: Step 1, design aluminum sleeve 4-1: the outer diameter of aluminum sleeve 4-1 is smaller than the diameter of hub groove 2-3 on lower die 2 by 15~ 20mm; step 2, making the aluminum alloy propeller hub 4: wrap the unidirectional carbon fiber cloth on the outer diameter of the aluminum sleeve 4-1, and the diameter of the winding is the same as the diameter of the propeller hub slot 2-3; step 3, cutting multiple upper dies Fiber cloth and multiple lower mold fiber cloths: the fiber cloth is cut into multiple upper mold fiber cloths according to the shape of each layer in the upper mold blade cavity 1-1-1 laid on the upper module 1, and the fiber cloth is laid according to the The shape of each layer in the lower mold blade chamber 2-1-1-1 on the lower module 2-1 is cut into multiple pieces of lower mold fiber cloth; The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com