Toughening ferromagnetic shape memory alloy and preparation method thereof

A memory alloy and ferromagnetic technology, applied in the field of shape memory alloy, can solve the problems of low strength and high brittleness of Ni-Mn-Ga, and achieve the effect of improving the toughness of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Take 50 parts of Ni, 30 parts of Mn, 18 parts of Ga and 2 parts of Cu in a vacuum non-consumable electrode arc furnace according to the molar ratio, and arc melting at 1600°C under the protection of inert gas After 13 minutes, clean the smelted metal block with acetone, and then put it into a vacuum with a degree of 10 -1 The Pa quartz tube was kept at 1000°C for 5 hours, and then quenched into water; the toughened magnetic shape memory alloy Ni was obtained. 50 mn 30 Ga 18 Cu 2 .

[0019] The vacuum non-consumable electrode electric arc furnace of this embodiment was purchased from Shenyang Science and Technology Instrument Co., Ltd.

[0020] The inert gas is helium, argon, neon or xenon. Others are the same as in the first embodiment.

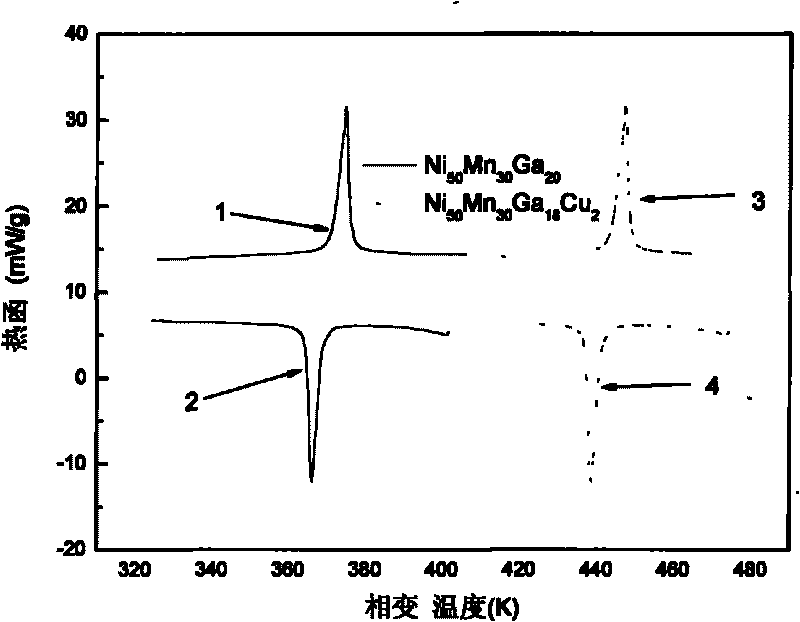

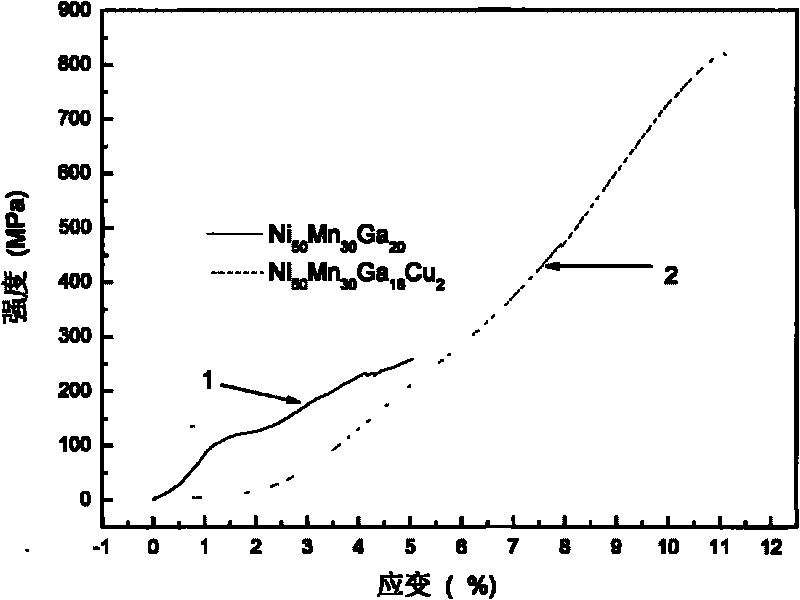

[0021] The prepared Ni 50 mn 30 Ga 18 Cu 2 The heating DSC curve 3 of the alloy was measured at a heating rate of 10K / min, and the cooling DSC curve 4 was measured at a cooling rate of 10K / min. Compared with the existing Ni ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com