Molding construction method of large-scale equipment foundation deep reserved foundation bolt hole

An anchor bolt and large-scale equipment technology, which is applied in the field of forming construction method of deep-type reserved anchor bolt holes for large-scale equipment foundations, can solve the problem of easy-to-scratch holes, difficult removal of deep-type reserved anchor bolt holes, and large holes. Inconvenience and other problems, to achieve the effect of saving costs and easy to obtain materials on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

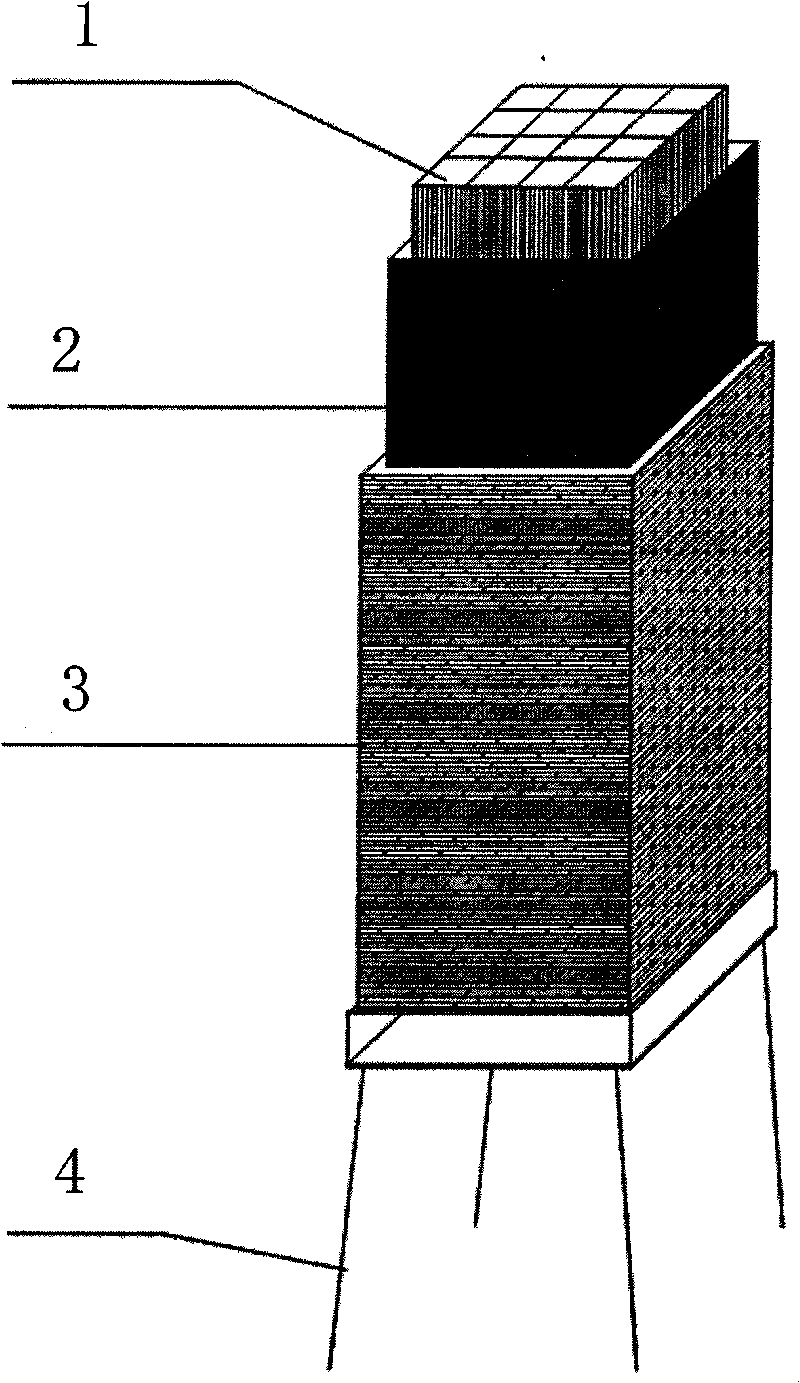

[0019] The technical scheme of the present embodiment comprises the following steps, as figure 1 shown

[0020] (1) To make the inner mandrel, select a plurality of dense square logs 1 as the material, plan the square logs to make the surface smooth and smooth, and use plastic binding ropes to bind the multiple square logs together into the shape required by the hole design The inner mandrel, the upper size of the hole is larger than the lower size, the length of the square wood on the outside of the inner mandrel should be 200-300mm longer than the designed hole depth, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com