Construction method for sand filling type damping sound-absorbing wood floor ground

A construction method and technology for wooden floors, which are applied to floors, buildings, building structures, etc., can solve the problems of pre-embedding of ground pipelines affecting wooden floors, complicated construction procedures, and high maintenance costs, achieving obvious shock absorption effect and easy maintenance. The effect of using ground materials and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, the present invention is further described:

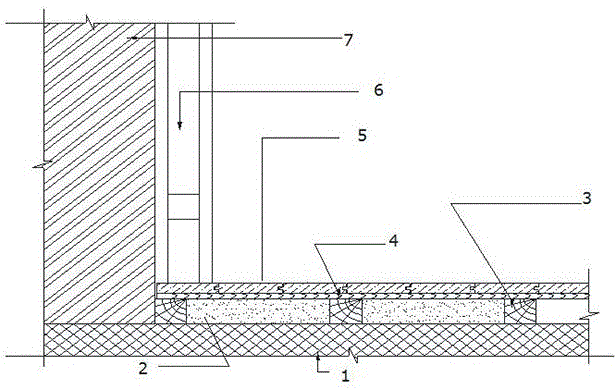

[0029] Such as figure 1 The construction method of the sand-filled shock-absorbing and sound-absorbing wooden floor shown in the construction sequence includes the following steps: structure base cleaning, leveling layer elevation and leveling layer cement fine stone concrete construction, wooden floor keel anti-corrosion treatment and wooden keel Laying and fixing, laying wiring pipelines in the wooden keel, filling dry medium-fine sand in the wooden keel, laying wooden slats, and laying the surface wooden floor.

[0030] The body steps of this embodiment are:

[0031] Structural base cleaning: Clean up the laitance, ground ash, garbage and other sundries on the concrete structure layer 1 and rinse with water.

[0032] Investing in leveling level and construction of cement fine stone concrete in leveling layer: use necessary measuring instruments and tools, mark the leveling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com