Expansion compensation device of solar evacuated collector tube and processing technology thereof

A vacuum heat collector tube and expansion compensation technology, applied in the field of expansion compensation devices, can solve the problems of complicated process, reduced connection strength and air tightness, affecting product performance, etc., and achieve the effects of simple operation, easy annealing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

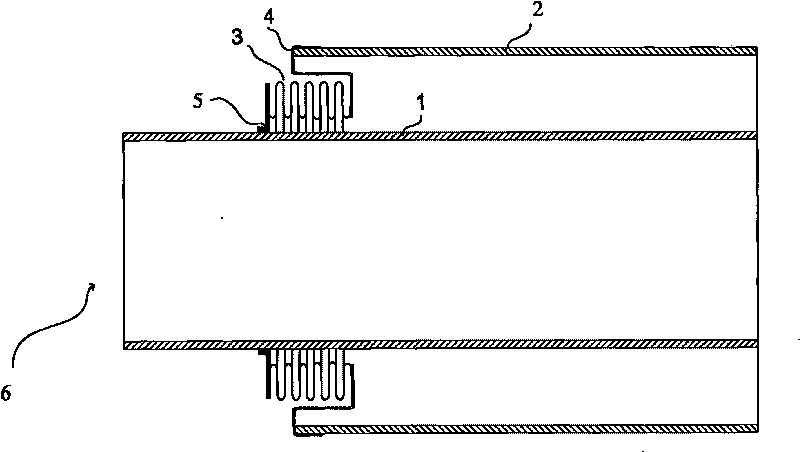

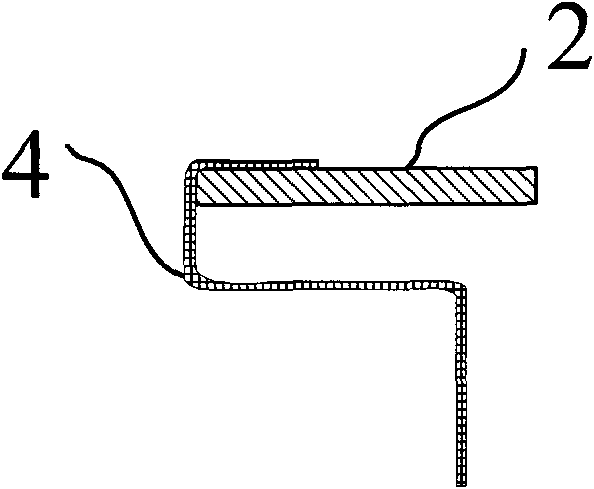

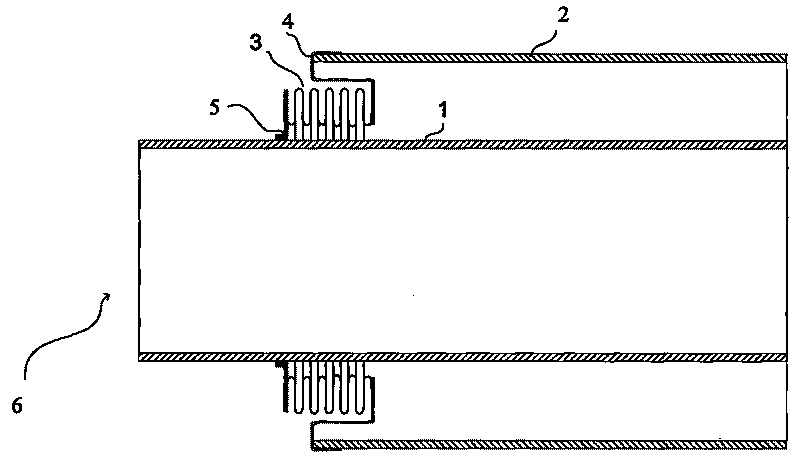

[0026] Such as Figure 1-2 As shown, a solar vacuum heat collecting tube 6 includes a metal inner tube 1 and a glass outer tube 2 coaxial therewith. The glass outer tube 2 is made of glass with high light transmittance, the metal inner tube 1 is made of stainless steel alloy, and the outer wall of the metal inner tube 1 is coated with a high-temperature selective absorption coating. The heat loss is reduced by vacuuming between the glass outer tube 2 and the metal inner tube 1, and the longitudinal thermal expansion stress is relieved by an expansion compensation device.

[0027] Specifically, such as Figure 1-2 As shown, the expansion compensation device described in the embodiment of the present invention adopts the bellows 3 with expansion compensation function. The bellows 3 is sleeved ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com