Easily branched cable

An easy-branching, optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of optical cable structure damage, limited number of optical fiber cores, and difficulty in production, and achieve stable optical cable performance, small optical cable volume, and large optical fiber capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

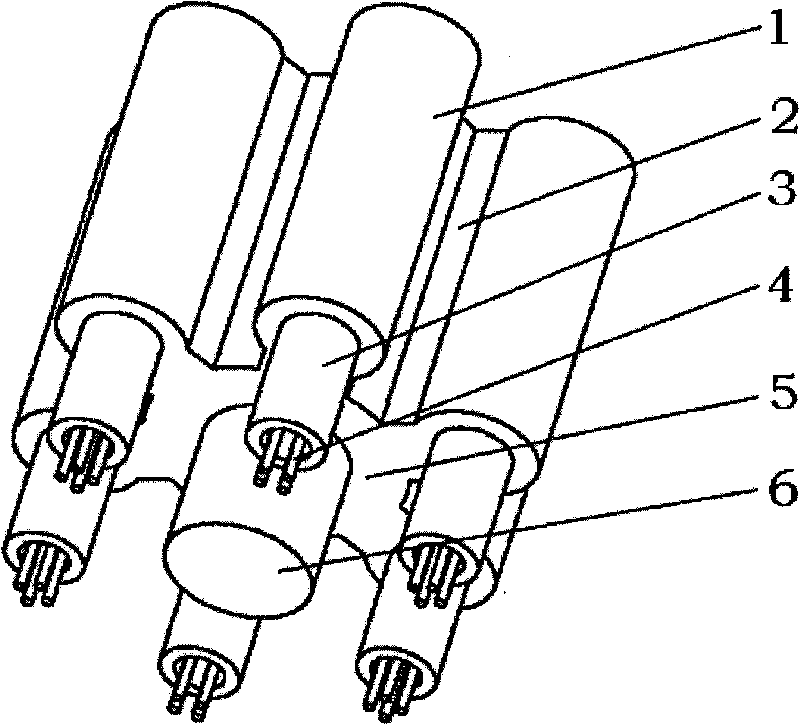

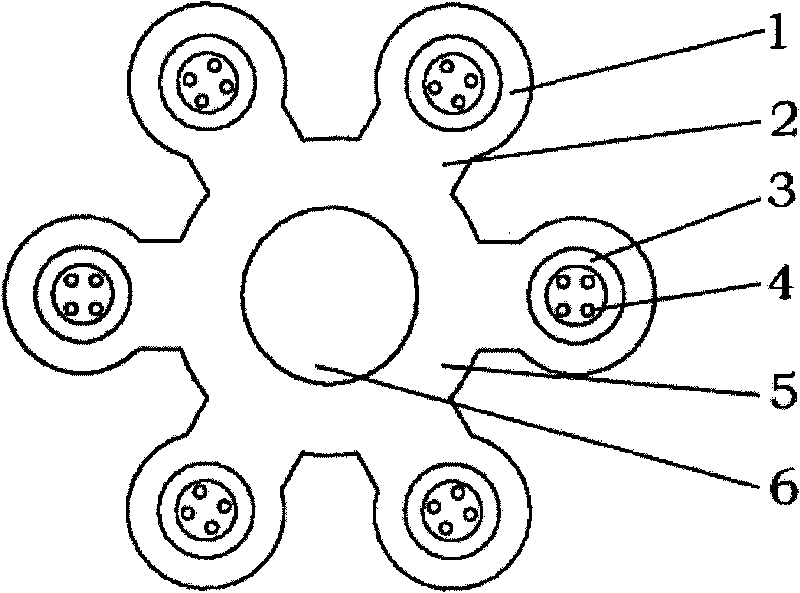

[0021] See figure 1 , figure 2 , a branchable optical cable, is characterized in that: it comprises six loose tubes 3, a central strength member 6 located in the center of the optical cable, an outer sheath 5 covering the central strength member as a whole, and coated on the loose tube 3 The outer suspension wire 1 and the rib 2 connecting the suspension wire 1 and the outer sheath 5; each of the loose tubes contains four optical fibers 4; the suspension wire 1 and the rib 2 are distributed around the outer sheath 5 and adjacent suspension wires There is a gap between the ribs; the suspension wire 1, the rib 2, and the outer sheath 5 are integrally formed and are of the same material; the central reinforcement is a metal wire; the material of the loose tube 3 is poly Butylene phthalate; the material of the suspension wire 1 or the rib 2 or the outer sheath 5 is medium-density polyethylene; the optical fiber 4 is a single-mode optical fiber.

Embodiment 2

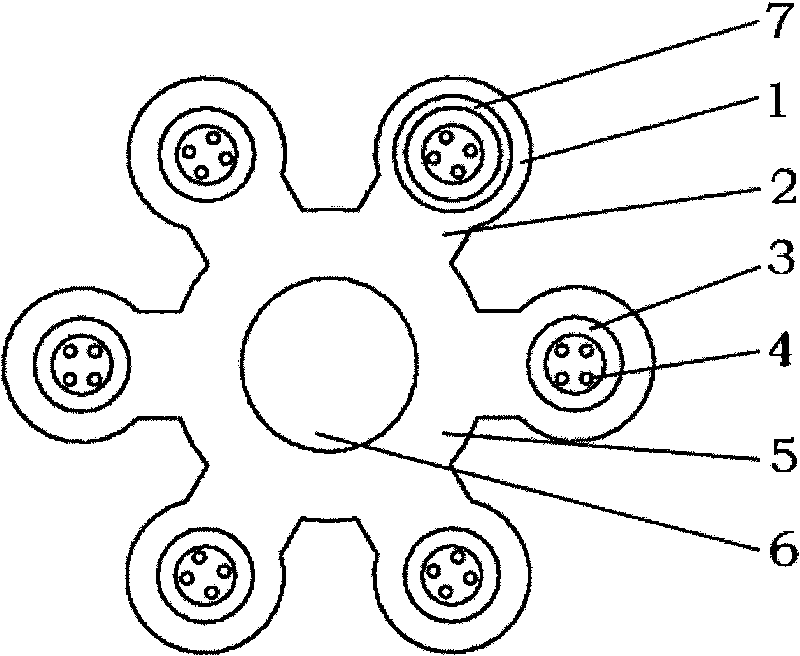

[0023] See image 3 , an optical cable that is easy to branch, basically the same as the implementation example 1, the difference is that: a loose tube 3 is covered with a protective layer 7; the protective layer 7 is located inside the suspension wire 1; the protective layer is water-blocking Tape or water blocking yarn or fiberglass tape or steel tape or aluminum tape or polyester tape.

Embodiment 3

[0025] See Figure 4 , a kind of easy-to-branch optical cable, which is basically the same as the implementation example 1, the difference is that there are four suspension wires and four ribs, there is a loose tube 3 in each of the two suspension lines, and there are two in each loose tube 3 Optical fiber 4; There is also a loose tube in another suspension line, four of which are located in the optical fiber ribbon 10; The loose tube in another suspension line is replaced by a single signal line, which is composed of conductor 9 and package It is composed of the sheath 8 covering the conductor; the conductor is a single metal.

[0026] Of course, the branchable optical cable described in any of the above embodiments is also characterized in that: when there are multiple optical fibers 4, they can be placed in the loose tube in the form of optical fiber ribbons.

[0027] Certainly, the branchable optical cable described in any of the above embodiments is characterized in that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com