Flexible electric braking method of large-sized water turbine generator

A hydraulic generator and electric braking technology, which is applied in the direction of controlling generators, electrical components, control systems, etc., can solve problems such as braking failure, improve reliability, add new functions for braking and starting, and overcome braking Effects of Failure Defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention has been implemented on a certain large-scale hydroelectric unit, which solves the problem of long-term braking failure of some units.

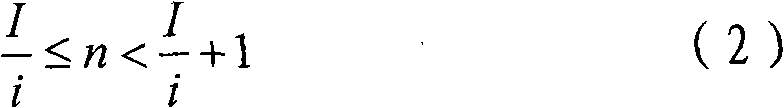

[0017] Example: A large hydroelectric unit with a rated excitation current of 4000A, the excitation design uses 5 rectifier bridges connected in parallel, and the rated output of a single bridge is 1800A. During electric braking, the setting value of excitation current is 1900A, and during electric braking, the number of input rectifier bridges can be selected as Substituting the values into n=2, 3, 4, the fewer the number of rectifier bridges participating in the output, the higher the rate of rise of the thyristor current, and the higher the success rate of braking. In this example, n is taken as 2 (the The smallest integer solution can also be used directly Solve the minimum integer solution), so when braking, the operation of 2 cabinets can be realized by cutting off the pulse of the other 3 bridges. After adopti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com