Vehicle seat slide device

A technology for sliding devices and vehicles, which is applied in the direction of vehicle seats, special positions of vehicles, movable seats, etc. It can solve problems such as dimensional tolerances and assembly errors, and achieve the effects of reducing sliding resistance, suppressing abnormal noise, and improving assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

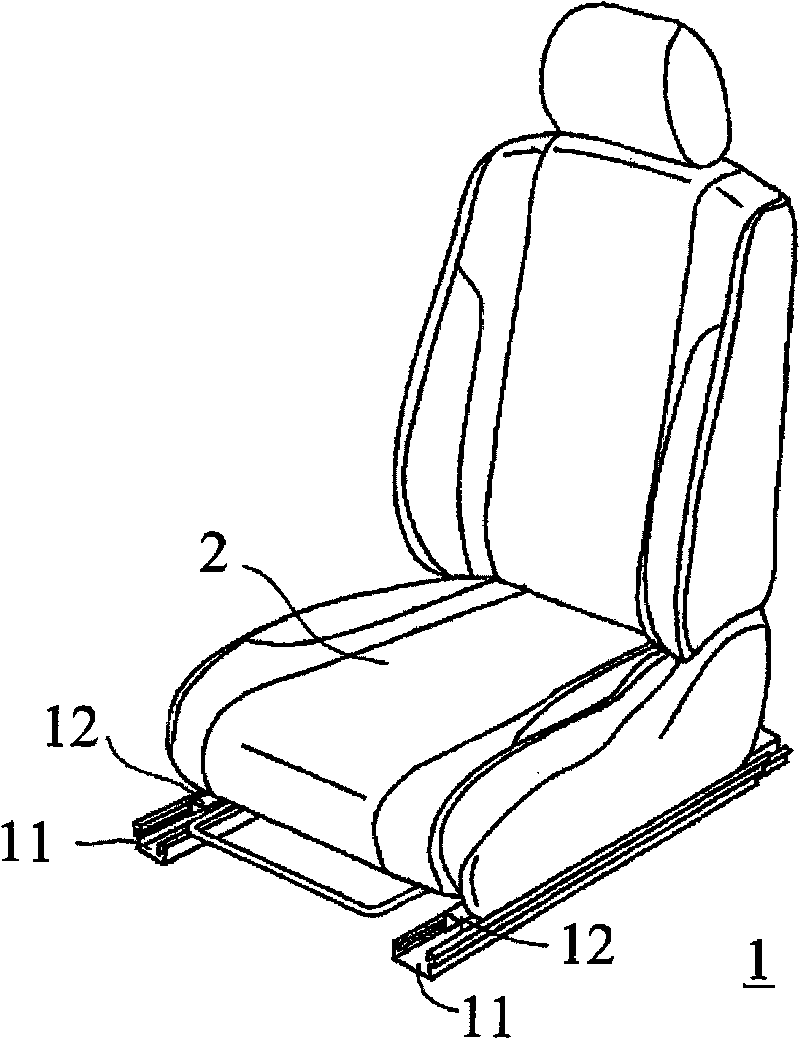

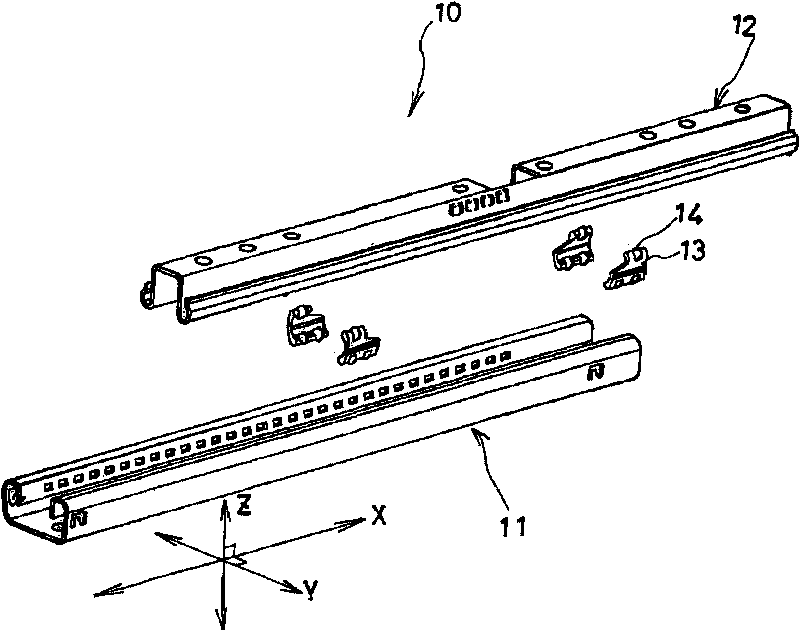

[0024] Next, a vehicle seat sliding device according to an embodiment of the present invention will be described with reference to the drawings.

[0025] Such as figure 1 , figure 2 , image 3 As shown, the seat sliding device 10 includes a pair of left and right lower side rails 11 fixed on the upper surface of the vehicle floor 1 and fixed on the lower surface of the vehicle seat 2 and respectively slidable relative to each lower side rail 11. A pair of left and right upper side rails 12 installed. The upper side track 12 can freely move towards the figure 2 The front-back direction X of the vehicle is shown moving by a predetermined amount.

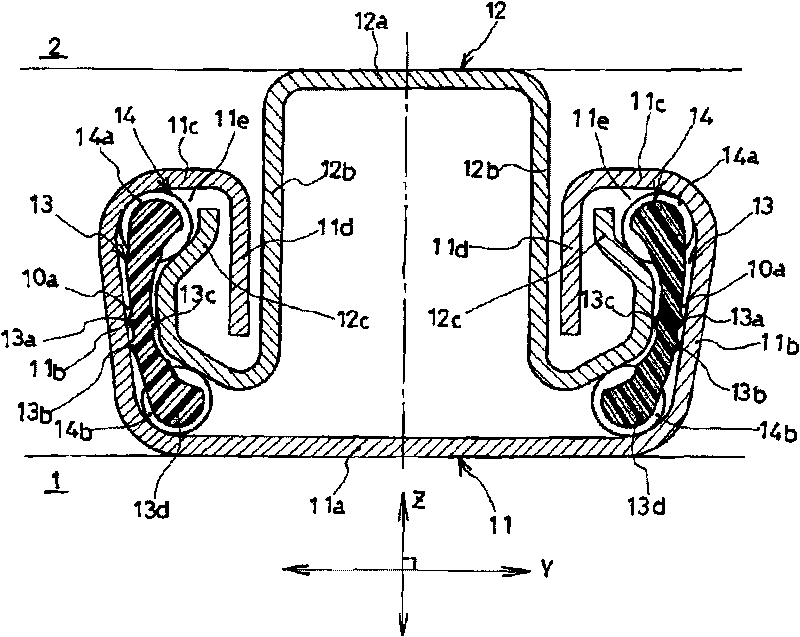

[0026] Next, a detailed structure of the seat slide device 10 will be described.

[0027] The lower rail 11 is formed by bending a sheet material. The lower rail 11 is extended long in the front-rear direction X of the vehicle, such as image 3 As shown, there is a planar bottom 11a and a pair of left and right upright walls 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com