Method for accurately controlling viscosity of molten state glass in platinum channel

A precise control, molten state technology, applied in glass forming, glass forming, glass manufacturing equipment, etc., can solve the problems of equipment failure, heat dissipation deviation, and no consideration of current carrying capacity of electric heating circuit, etc., to reduce energy consumption , high degree of automation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

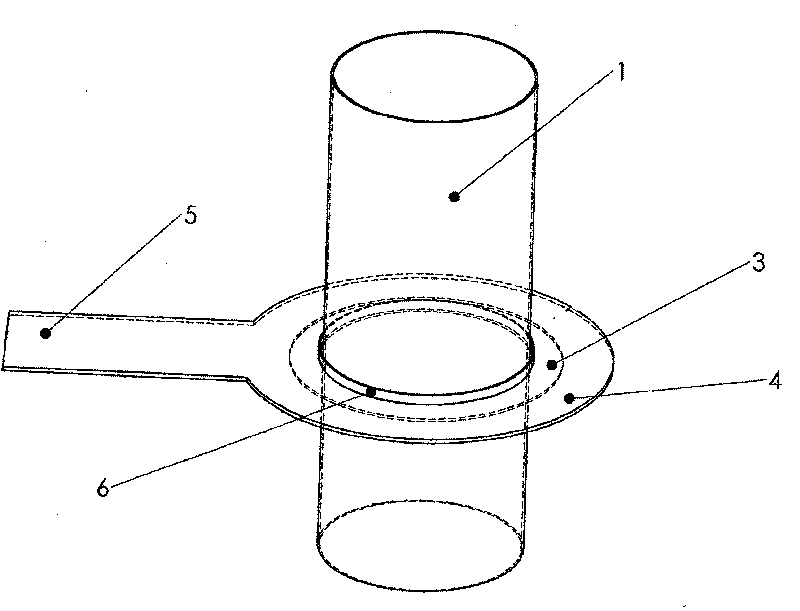

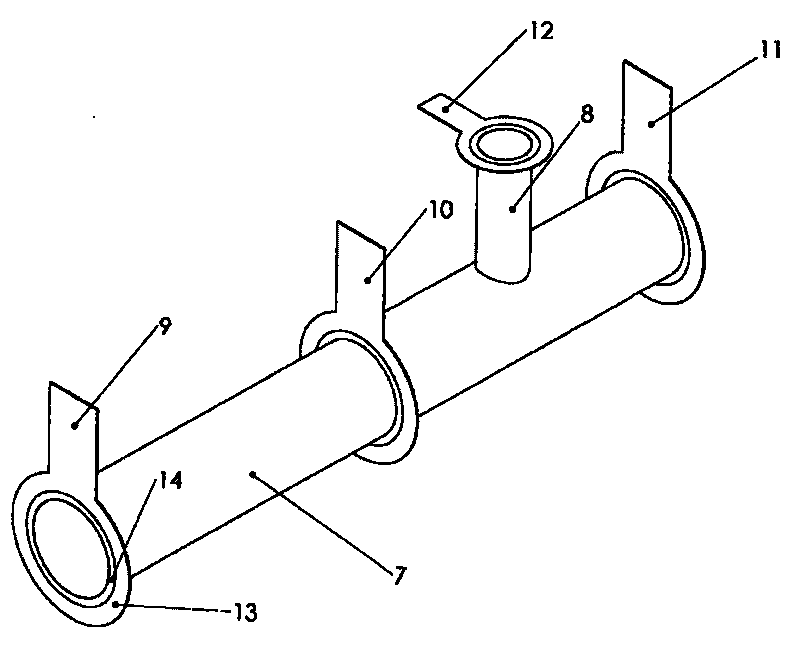

[0065] The platinum channel is divided into zones and sections according to the process conditions, and flanges for power supply are installed at the ends of each zone. For a segment, all non-end flanges and partly end flanges used for the segment are shared by at least two electric heating circuits with current flowing through at least two circuits at the same time.

[0066] The structure of the flange includes a current sharing outer ring 4 , a current leading inner ring 3 , a flanging structure 6 for welding positioning, and a current leading end 5 .

[0067] The flange structure also includes a cooling water channel, which is connected to a cooling water circulation system regulated by a management circuit.

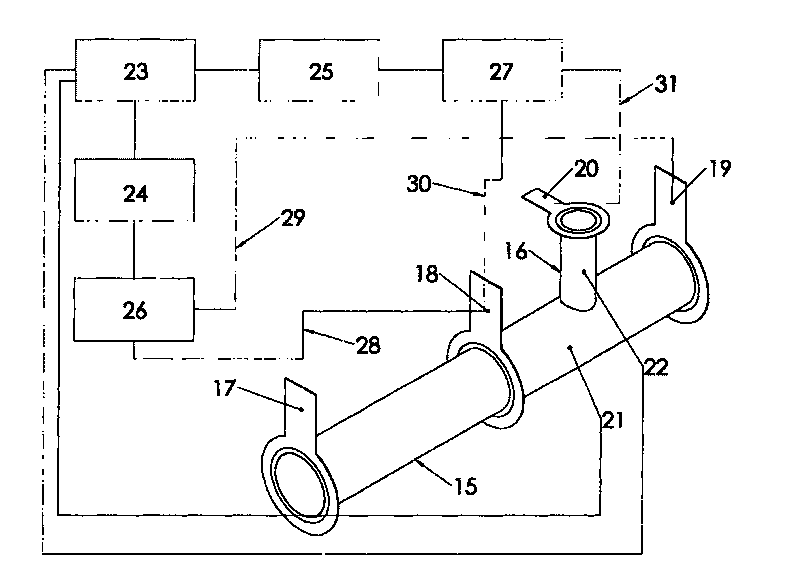

[0068] The above-mentioned management circuit includes a matching voltage-regulating power regulator, which applies the regulated voltage to the platinum channel of the corresponding area and section through the flange.

[0069] The above management circuit structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com