Extrusion molded article

A technology of extrusion molding and extrusion direction, which is applied in the direction of catalyst carrier, dispersed particle separation, grinding/polishing equipment, etc., can solve the problems of easy cracking and cracking, and achieve the effects of cracking resistance, cracking reduction and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

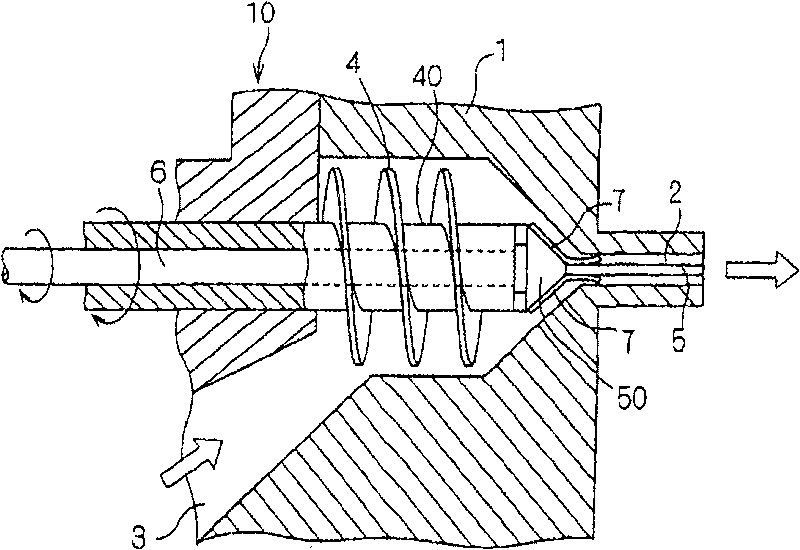

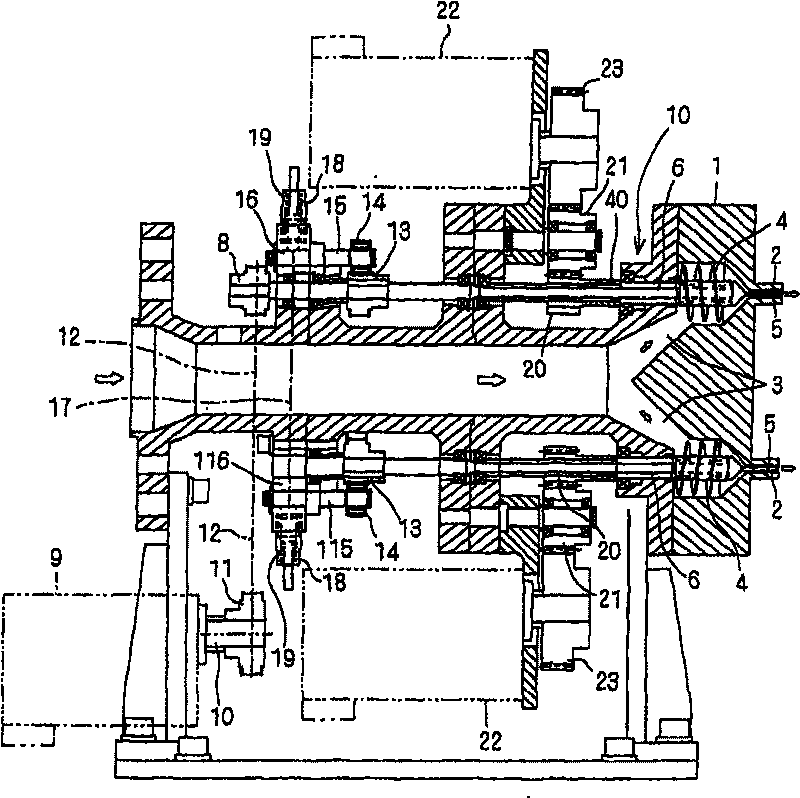

[0054] use figure 1 , figure 2 The extrusion molding apparatus shown extrudes a clay-like alumina catalyst molding material to manufacture its molded product. The alumina molding material contained 6 parts by weight of alumina fibers having an average fiber length of 0.4 mm and 38 parts by weight of water relative to 100 parts by weight of the catalyst.

[0055] The used die 1 has a chrome-plated surface and has a disc shape in which eight extrusion holes 2 are concentrically arranged. The inner diameter of the extrusion hole 2 is 6.6 mm, and the length is 10 mm.

[0056] A pin 5 with an inner diameter of 2.5 mm and a length of 22 mm is inserted into the extrusion hole 2 . like figure 1 As shown, the rear ends of the three metal wires are fixed on the pin 5, wound on the pin 5 obliquely, and the front ends are slightly tilted from the pin 5.

[0057] Using this extrusion molding apparatus, the above-mentioned alumina catalyst molding material was extrusion-molded at an e...

Embodiment 2

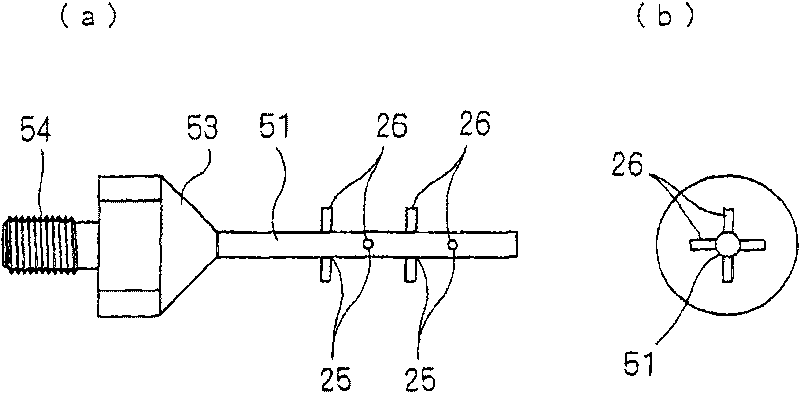

[0059] In addition to using image 3 pin 51 shown in place of the figure 1 Extrusion molding was carried out in the same manner as in Example 1 except for the pin 5 shown. However, the number of wires 26 fitted in the through holes of the pins 51 is two, and the intersection angle of the two wires 26 is 90°.

Embodiment 3

[0061] In addition to using Figure 4 pin 52 shown in place of the figure 1 Extrusion molding was carried out in the same manner as in Example 1 except for the pin 5 shown. However, the number of cross-shaped rings 28 is one.

[0062] [Comparative example]

[0063] Extrusion molding was carried out in the same manner as in Example 1, except that a pin without protrusions was used.

[0064] The strength of the molded articles obtained in the above-mentioned Examples and Comparative Examples was investigated by the following drop test and compressive strength test.

[0065] 〔Compressive strength test〕

[0066] When a pressure is applied along the thickness direction (radial direction) of a molded product with a cutting length of 6.6 mm, the pressure at which the molded product breaks is measured, and this value is taken as the compressive strength.

[0067] 〔Drop strength test〕

[0068] Put the molded product with a cut length of 6.6mm in an environment of 25°C and 80%RH, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com