Method and system for cutting decorative adhesive film of digital product

A technology of digital products and cutting methods, which is applied in metal processing and other fields, can solve the problem that the film cannot be cut automatically, and achieve the effect of increasing the range of options, reducing costs, and reducing inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

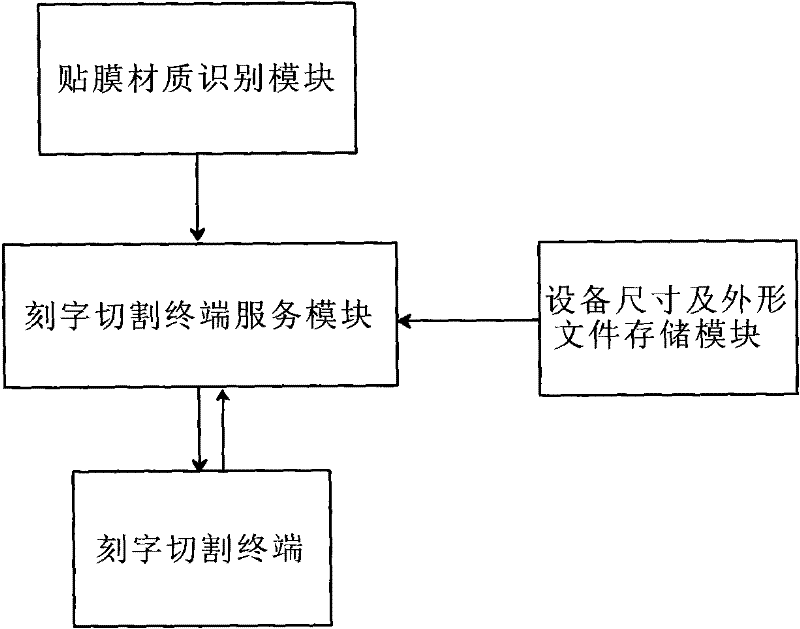

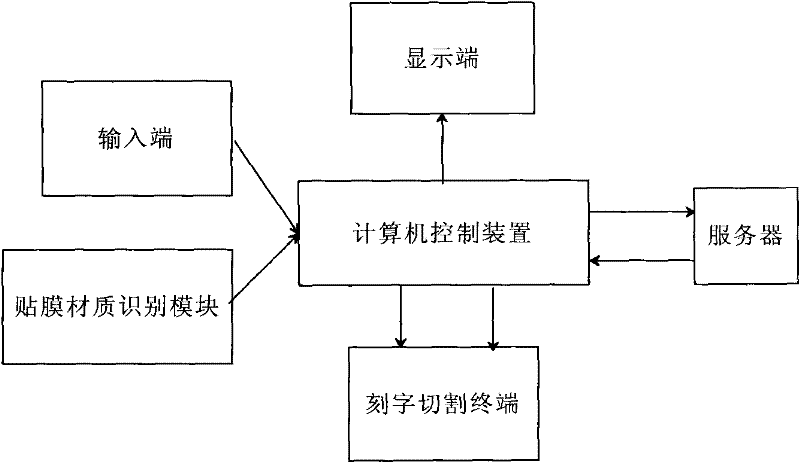

[0042] This embodiment is used for cutting a 14-inch Hewlett-Packard brand model is the sticking film of the notebook computer of CQ45-202. In the system of this embodiment, the lettering and cutting terminal is a numerical control cutting machine, and data transmission between modules is realized through the Internet. The surface of the film to be processed is affixed with an RFID label recording the material information of the film.

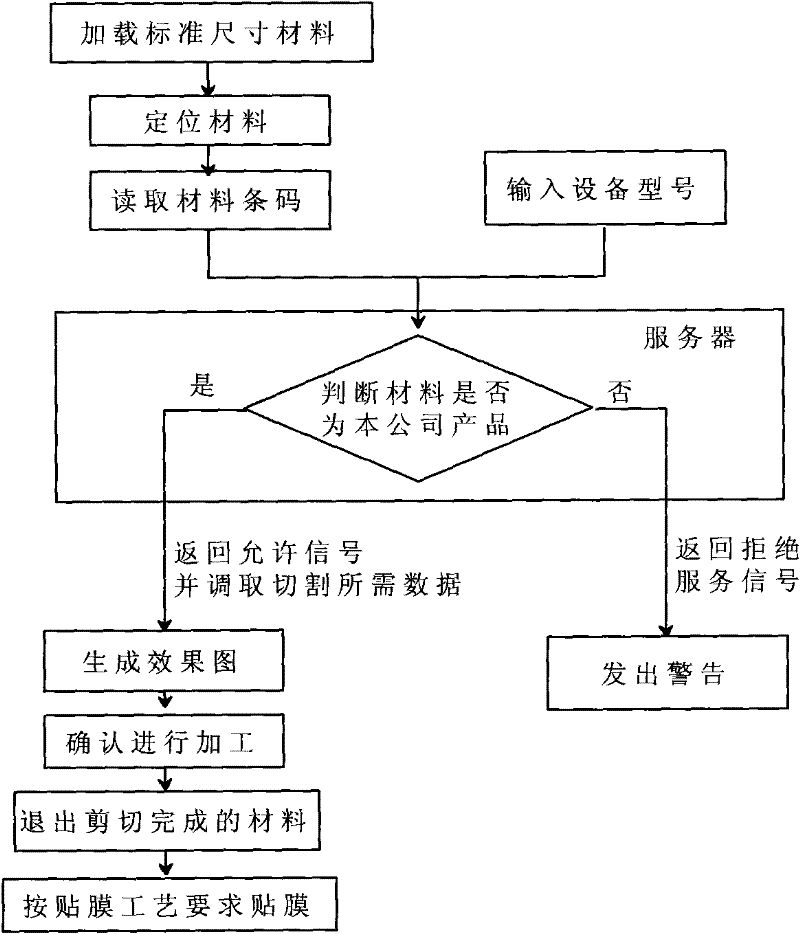

[0043] Such as figure 1 Shown, the embodiment of the inventive method comprises the steps:

[0044] Step 1, set the material code (RFID tag) on the surface of the film material, and the material code records the material information of the film;

[0045] Step 2, positioning the film material (14 inches) processed in step 1 on the designated position of the lettering cutting terminal, and the user inputs the brand and model (HP, CQ45-202) of the equipment that needs to process the film to the computer system;

[0046] Step 3, the computer s...

Embodiment 2

[0056] This embodiment is used to cut a 11-inch ASUS card model S6323F-DU notebook computer film.

[0057] In the system of this embodiment, the lettering cutting terminal is a numerical control cutting machine, and the method and system of this embodiment are generally the same as those of Embodiment 1, except that:

[0058] 1. The surface of the film to be processed is affixed with a barcode label recording the material information of the film;

[0059] 2. The system modules in this embodiment are all physically connected to realize data transmission, and the data information in the device size and shape file storage module is regularly updated through portable storage devices or intermittent networked UPDATEs according to the launch of new products ;

[0060] 3. Whether the authenticity judgment module in the server judges whether the film is available refers to judging whether the material characteristics of the material are suitable as a film for corresponding equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com