Method for manufacturing segmental box girder

A manufacturing method and segmental technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as large footprint, achieve high degree of streamlining, improve matching prefabrication quality, and intuitive linear control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

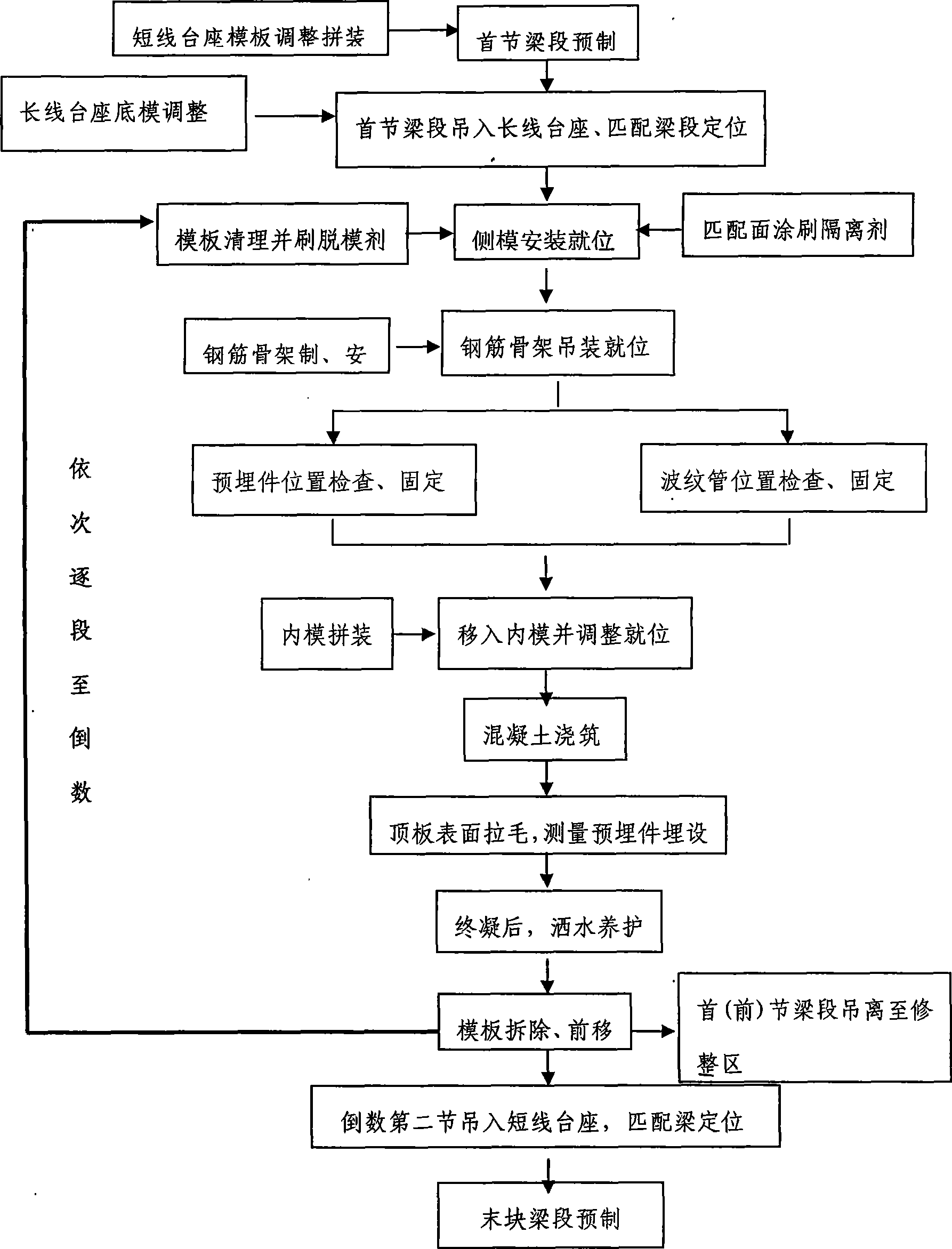

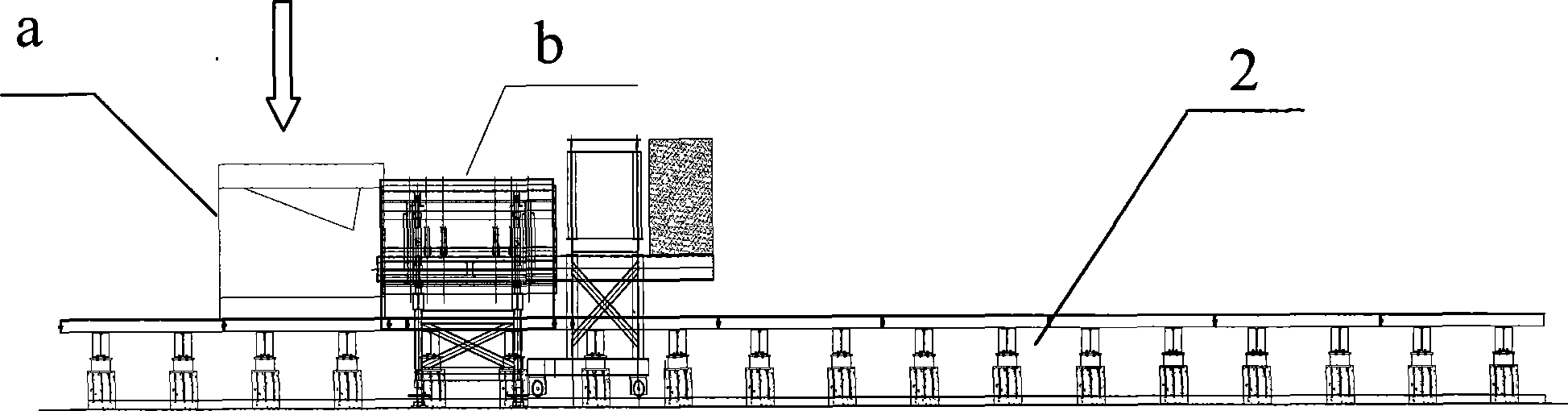

[0041] In order to achieve a good manufacturing process, a process flow provided by the present invention is as follows figure 1 and Figure 9 , and each process manufacturing process such as Figure 2-5 , the specific implementation is as follows:

[0042] A method for manufacturing a segmental box girder, the main steps are as follows:

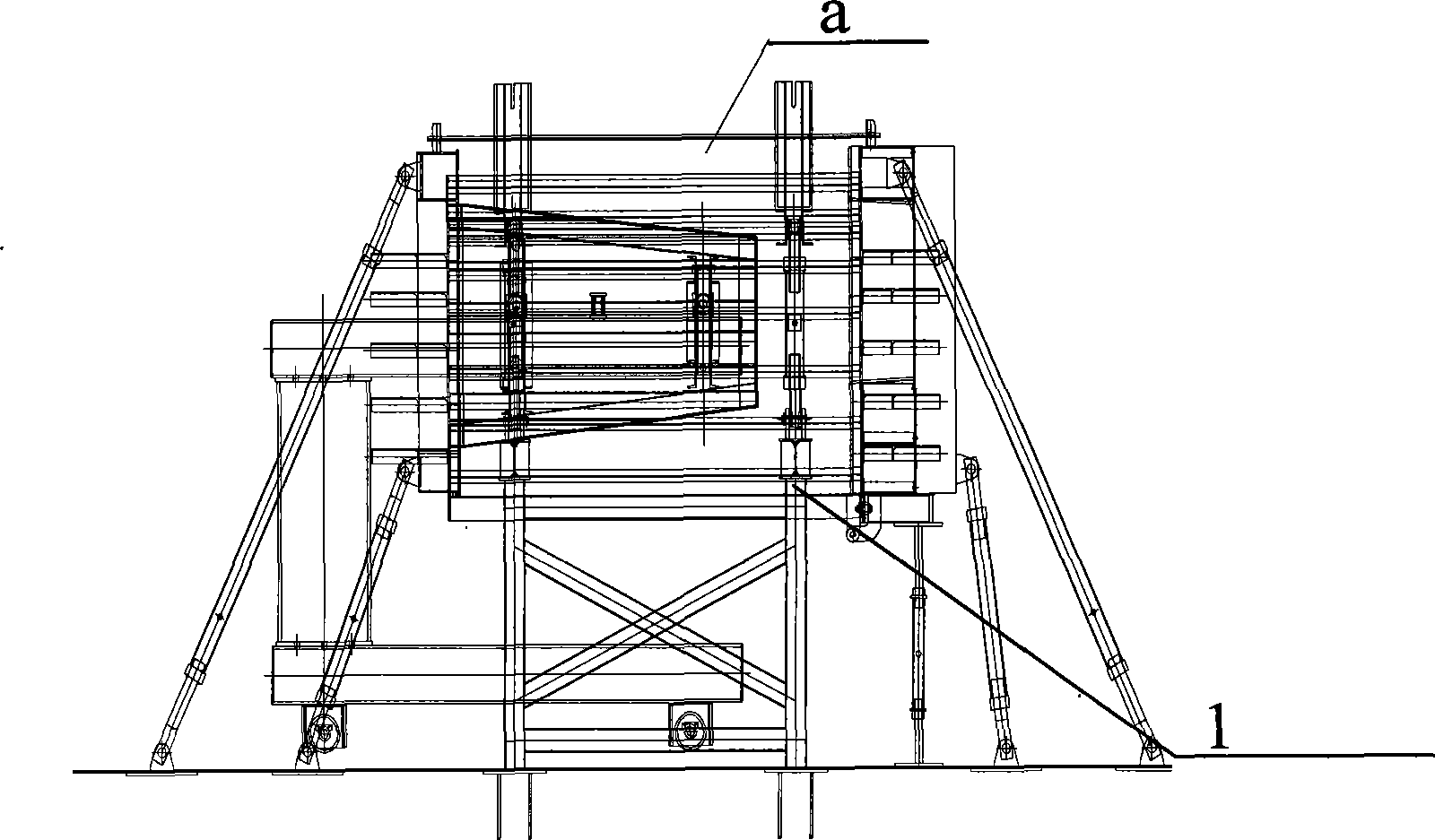

[0043] (A) In the prefabrication factory, according to the span combination requirements of the bridge, a number of prefabricated long-line pedestals 2 and short-line pedestals 1 are set up in the prefabricated factory. Considering various linear influence factors, the coordinate system conversion is carried out, and the long-line is adjusted according to the linear requirements of a certain span box girder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com