Calibration method and device of embedded-type long-distance optical fiber sensor

A technology of long-distance optical fiber and calibration method, which is applied in the direction of using optical devices, measuring devices, instruments, etc., and can solve the problems of unusable parameter indicators and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

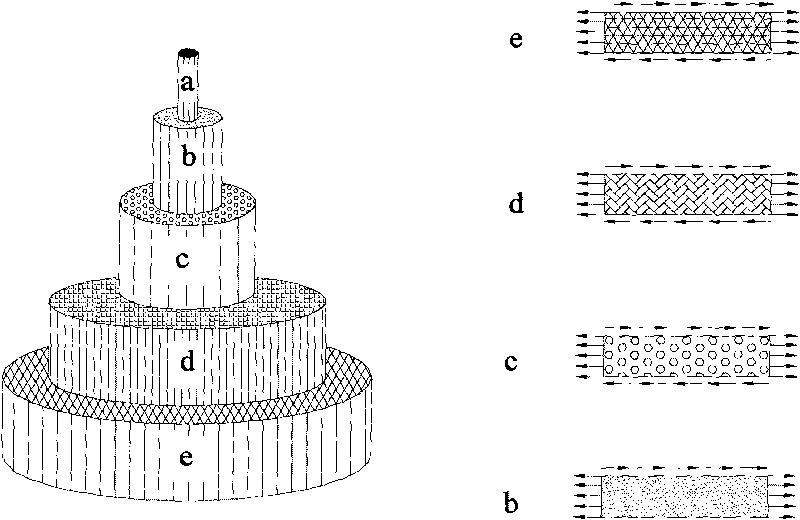

[0041] In this embodiment, the aluminum-plastic tube composite tube with a diameter of 16mm in the microtube, the sensing fiber is a 4mm tight-buffered fiber, and the embedded long-distance sensing fiber uses cement slurry poured into the microtube as a bonding layer to fix the sensing fiber. Structural and mechanical models such as figure 1 shown. The embedded optical fiber sensor is a multi-layer interface transfer model, but the elastic modulus of the cement slurry filling layer d in this model is similar to the elastic modulus of the fiber core a and the matrix material, so the optical fiber coating is required when the structural strain is transmitted to the fiber core Elastic modulus of layer b, cladding c and microtube e. The strain is transmitted between the layers through shear force. According to the common shear lag theory and assuming that the layers are deformed synchronously, the relationship between the optical fiber strain and the matrix strain can be obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com