Analysis method and device of geometric tolerance influencing control precision of track of machine tool

A technology of geometric tolerance and trajectory control, applied in the field of virtual design, can solve the problems of comprehensive analysis of geometric tolerance and trajectory control accuracy of machine tools, and achieve the effects of shortening design time, saving design cost, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The recommended embodiments of the geometrical tolerance analysis method and device that affect the trajectory control accuracy of the machine tool provided by the present invention are described below.

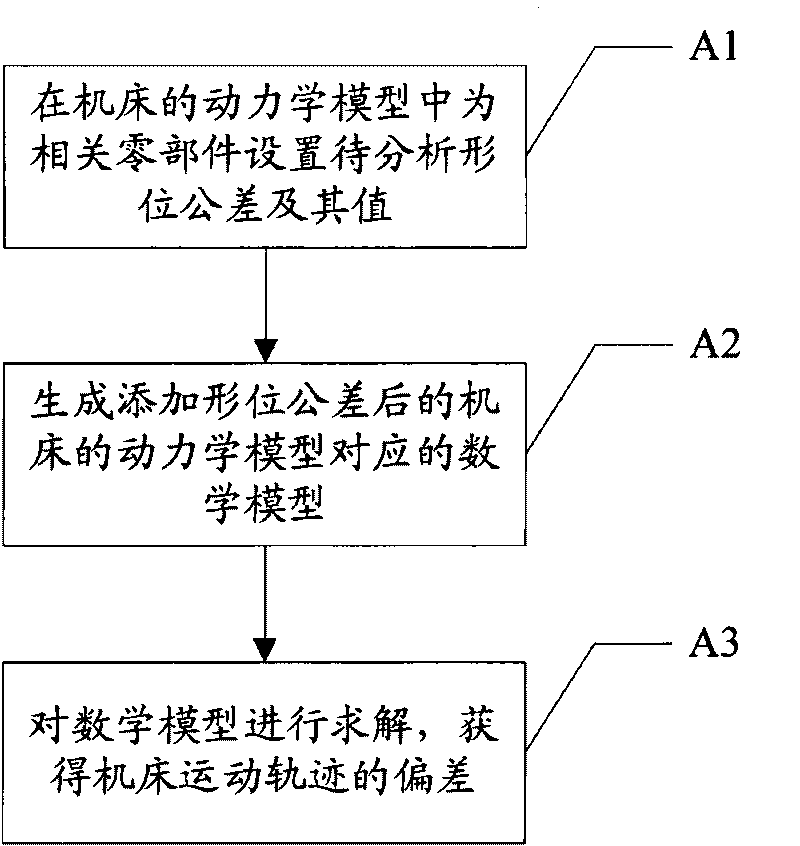

[0024] refer to figure 1 , the present invention affects the shape and position tolerance analysis method embodiment of the trajectory control accuracy of the machine tool comprising:

[0025] A1. In the dynamic model of the machine tool, set the geometric and position tolerances for the key components to be analyzed.

[0026] Shape and position tolerance has the characteristics of adjustable tolerance value and change of tolerance zone direction. In the embodiment of the present invention, it is possible to analyze different shape and position tolerances (such as straightness, non-parallelism, coaxiality, flatness, etc.) on different parts on the machine tool according to actual working conditions, and all shape and position tolerances A geometric tolerance group ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com