Induced metamagnetic generating method

A technology that induces current and the direction of magnetic lines of force, applied in the direction of electrical components, can solve problems such as low conversion efficiency, hazards to the power grid, and increased resistance, and achieve the effects of improving power generation efficiency, saving energy, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

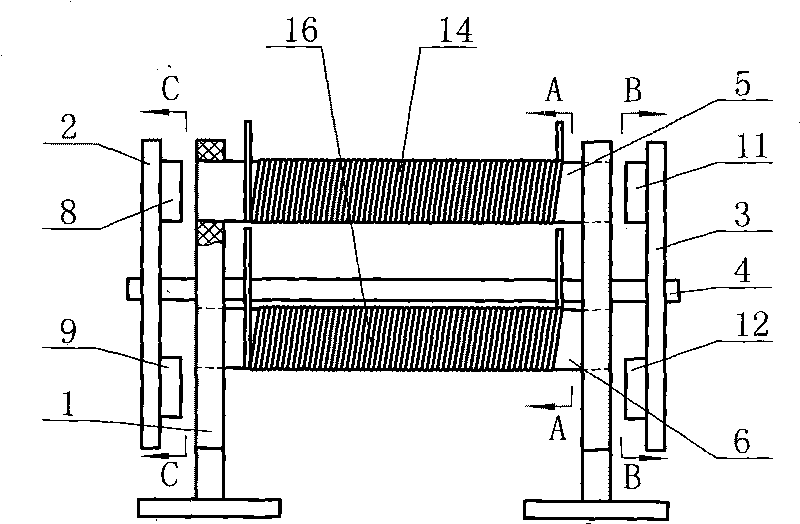

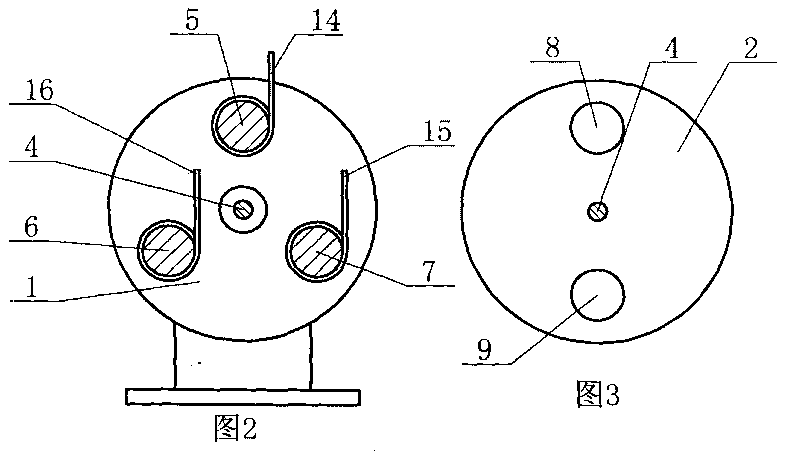

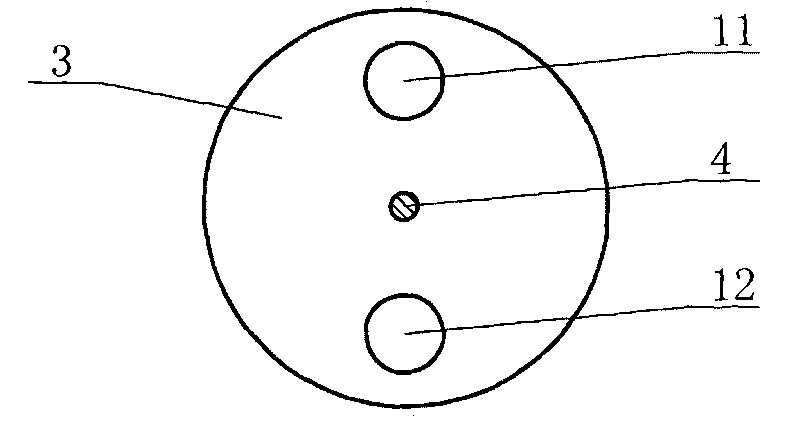

[0009] The induction variable magnetic power generation method described in the present invention uses at least one iron core and at least one magnet group, and a coil is installed on each iron core, and each group of magnets is composed of two magnets, and the two magnets of the same group are opposite to each other. Utilize the relative movement between the iron core and the magnet to change the magnitude of the magnetic flux in the iron core, so that the magnetic flux in the iron core gradually increases from zero to the maximum value, and then gradually decreases from the maximum value to zero. The induced current is generated in the coil, the specific steps are as follows:

[0010] First place the two magnets in each pair of magnets on the front and rear sides of the iron core respectively, and make the magnetic force lines between the two magnets in the same group parallel to the axis of the iron core;

[0011] Then make each magnet group rotate around the same circle ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com