Blended composite modified asphalt and preparation method thereof

A composite modified asphalt and blending technology, which is applied to building components, building insulation materials, buildings, etc., can solve the problem of large amount of modified asphalt material polymer, complex equipment, high temperature rigidity, low temperature flexibility, etc. problem, to achieve the effect of improving the comprehensive waterproof performance of asphalt, lowering the price, and alleviating white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

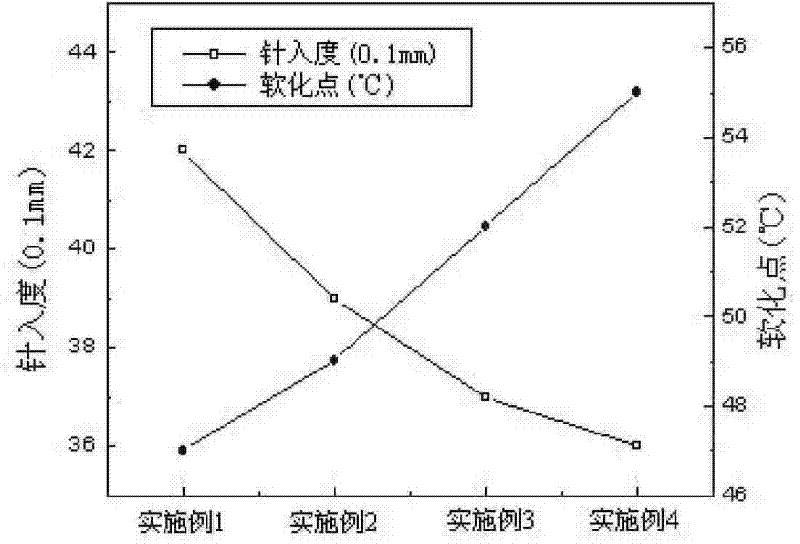

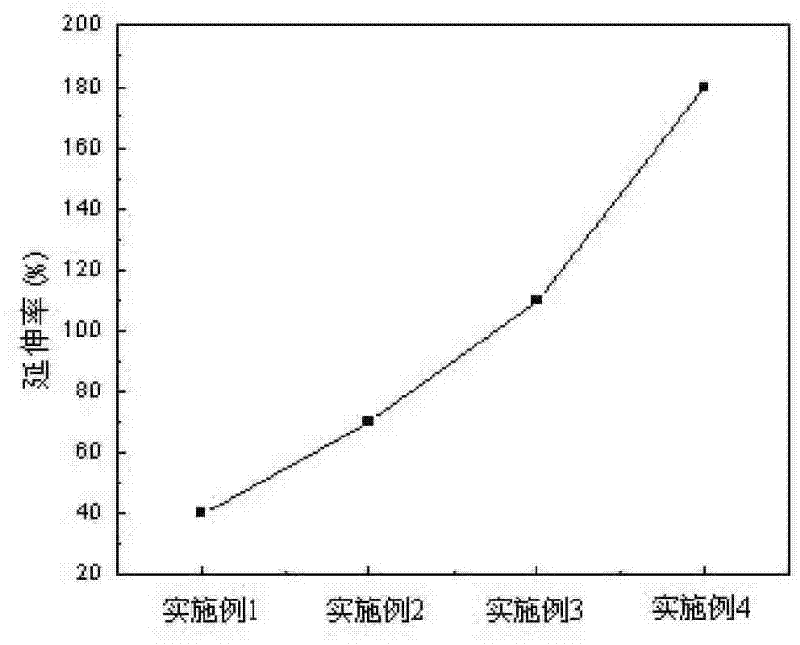

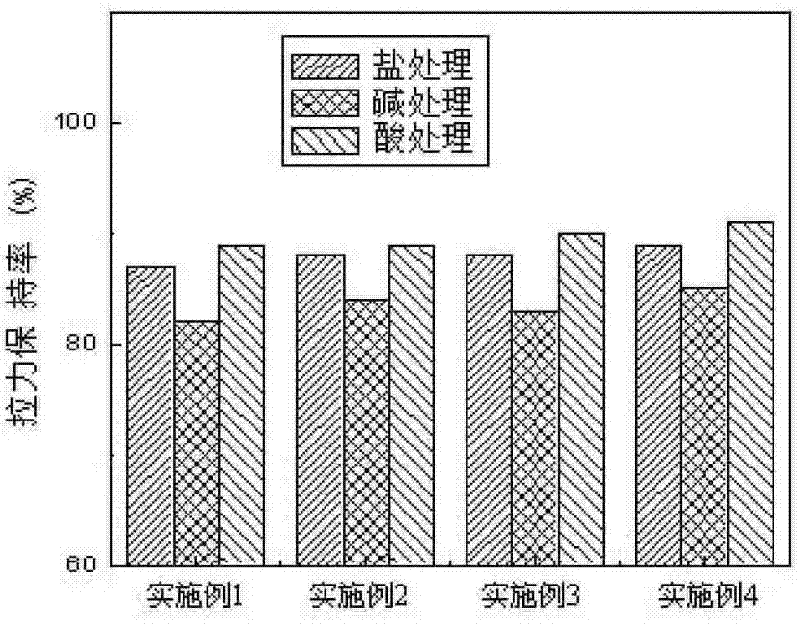

Embodiment 1

[0037]Take by weight 2% waste packaging polymer EVA, 5% waste tire powder, 90.5% matrix asphalt, 0.5% divinylbenzene, 2% p-toluenesulfonic acid at a temperature of 150 ° C. Melt the weighed base asphalt, add waste packaging polymer EVA and waste tire powder to the melted base asphalt, keep the temperature constant, manually stir for 20 minutes, add divinylbenzene and p-toluenesulfonic acid, and stir with shears 100min to obtain the blended composite modified asphalt.

Embodiment 2

[0039] Take by weighing 6% waste packaging polymer EVA, 15% waste tire powder, 77.98% matrix asphalt, 0.02% divinylbenzene, 1% p-toluenesulfonic acid according to mass percentage, and put The weighed base asphalt is melted, waste packaging polymer EVA and waste tire powder are added to the melted base asphalt, the temperature is kept constant, manual stirring is carried out for 40 minutes, divinylbenzene and p-toluenesulfonic acid are added, and shearing machine is stirred After 120 minutes, the blended composite modified asphalt was obtained.

Embodiment 3

[0041] Take by weighing 6% waste packaging polymer EVA, 2% waste tire powder, 89.5% matrix asphalt, 0.5% divinylbenzene, 2% p-toluenesulfonic acid according to mass percentage, and put them at a temperature of 160°C Melt the weighed base asphalt, add waste packaging polymer EVA and waste tire powder to the melted base asphalt, keep the temperature constant, manually stir for 30 minutes, add divinylbenzene and p-toluenesulfonic acid, and stir with shears After 120 minutes, the blended composite modified asphalt was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com