M-shaped support system of derrick for sheave platform shaped like a Chinese character mu

A technology of a sky wheel platform and support system, which is applied in drilling equipment, support devices, earthwork drilling and mining, etc., can solve the problem of uneven stress on the derrick system, mismatch between the nodes of the sky wheel platform beam and the fulcrum of the support system, and problems with the sky wheel platform beam. Excessive internal force and other problems, to achieve the effect of reasonable force, reduced vertical inclination, and uniform distribution of internal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

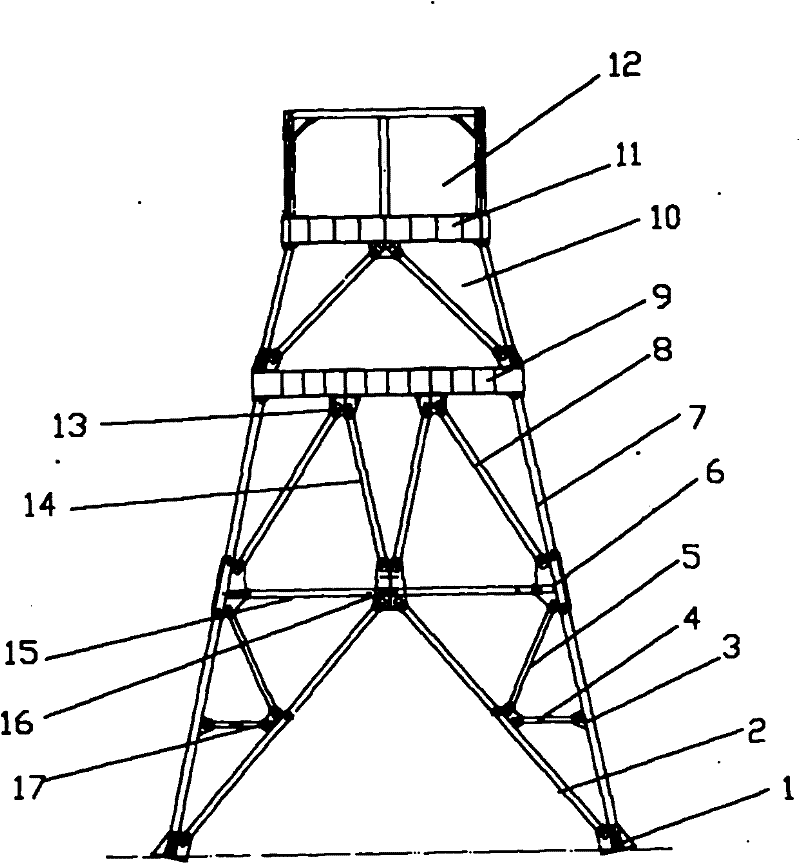

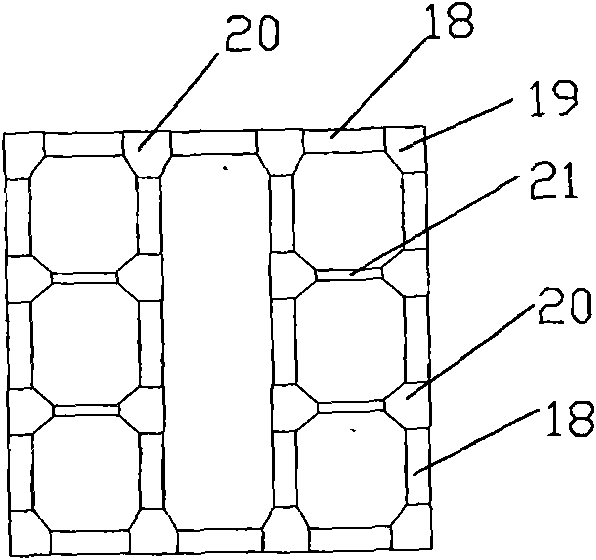

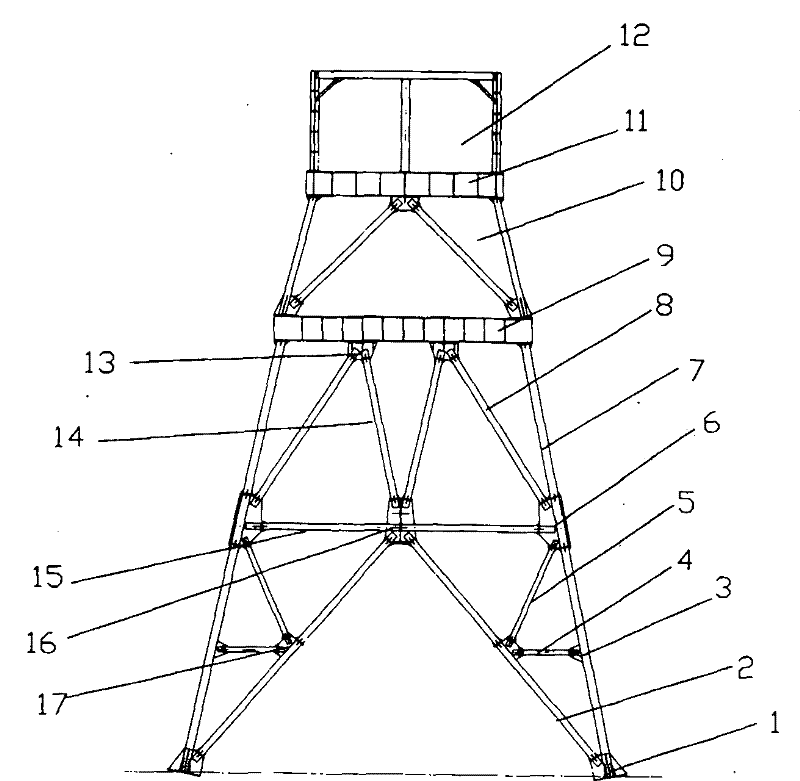

[0020] figure 1 Middle: The M-shaped derrick support system of the mesh-shaped sky wheel platform consists of node I1, herringbone support 2, node II3, small horizontal support 4, small vertical support 5, node III6, trapezoidal support 7, M-shaped support I8, mesh-shaped The sky wheel platform 9, the small trapezoidal support body 10, the Japanese-shaped sky wheel platform 11, the sky wheel house 12, the node IV13, the M-shaped support II14, the large beam 15, the node V16, and the node VI17. Its trapezoidal support 7, large crossbeam 15 and node III6 are connected to form a trapezoid, and the upper end of M-shaped support I8 on the large crossbeam 15 is connected to node III6. M-shaped support I8 and connected node III6 form an M-shaped support. Node I1 below the large beam 15 is connected to herringbone support 2, node V16, herringbone support 2, and node I1 in turn to form a herringbone. The lower end of node III6 is connected to node VI17, and then connected to small hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com