Method for inspecting element collision of power generation plant by three-dimensional model

A technology of 3D model and power plant, applied in the field of 3D design and 3D design of electric power engineering, to achieve the effect of saving time, improving work efficiency and avoiding secondary inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

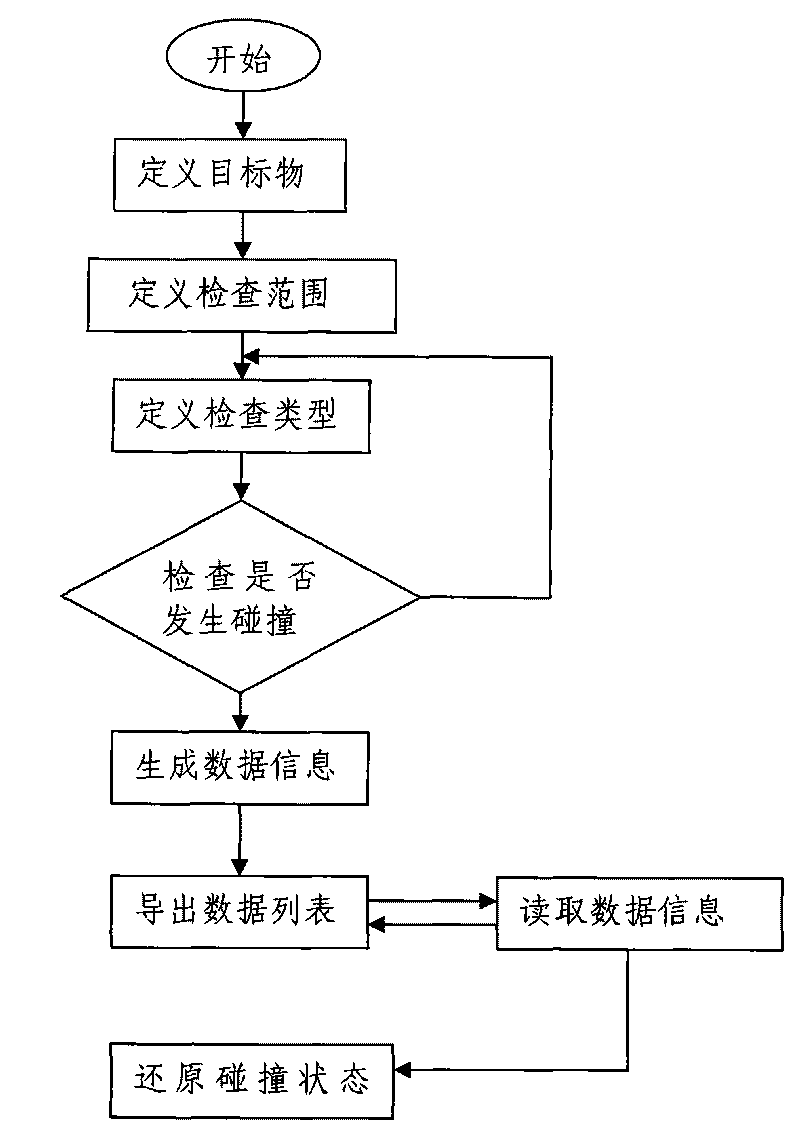

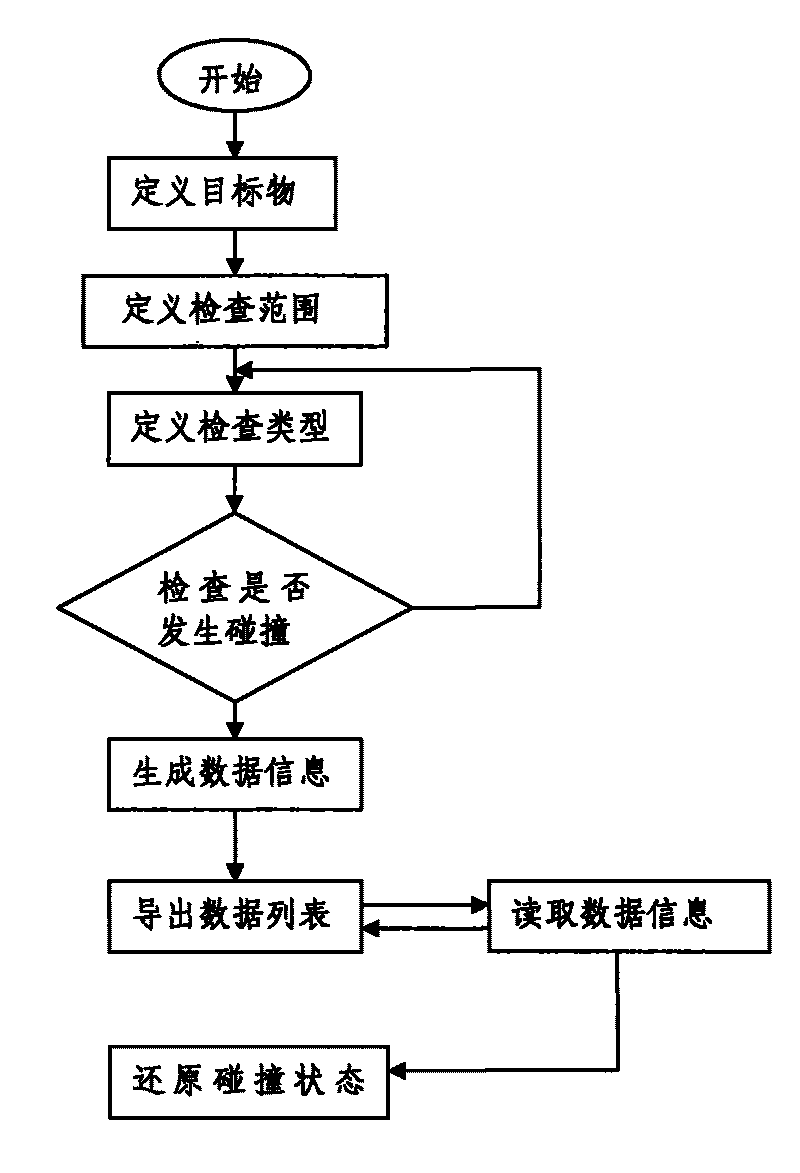

[0022] On the basis of the 3D design integration system, each solid model has its own spatial position, judge whether the target object collides with other models of the system in the 3D model space, and export the collision results, figure 1 It is a flow chart of a method for checking the collision of power plant components with a three-dimensional model, the method includes the following steps:

[0023] a. Select the target object in the three-dimensional model space of the system, and store the three-dimensional coordinate values of each point of the solid model of the target object; for example: the selected target object is "J0902-LBA-main steam pipeline installation drawing";

[0024] b. In the 3D model space of the system, select the range where the solid model that needs to be checked for collision is located, and store the 3D coordinate values of all poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com