Blazed grating external cavity semiconductor laser and collimating method thereof

A blazed grating and laser technology, which is applied to the device for controlling the output parameters of the laser, the structure of the optical resonator, etc., can solve the problems of complex manufacturing, low wavelength adjustment accuracy, low mechanical stability, etc., and achieve the effect of high-precision tuning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

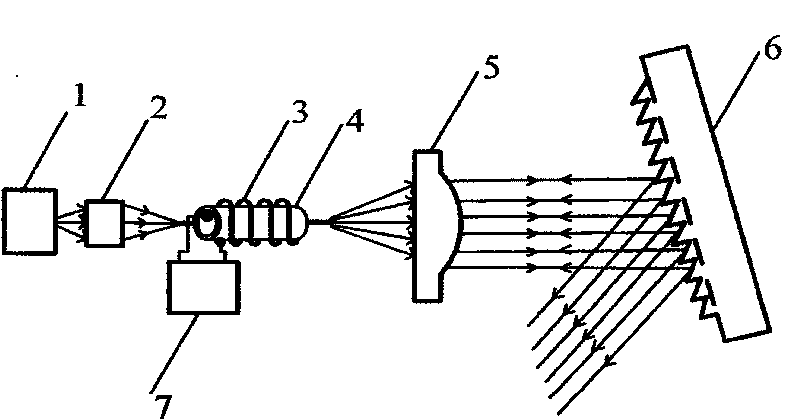

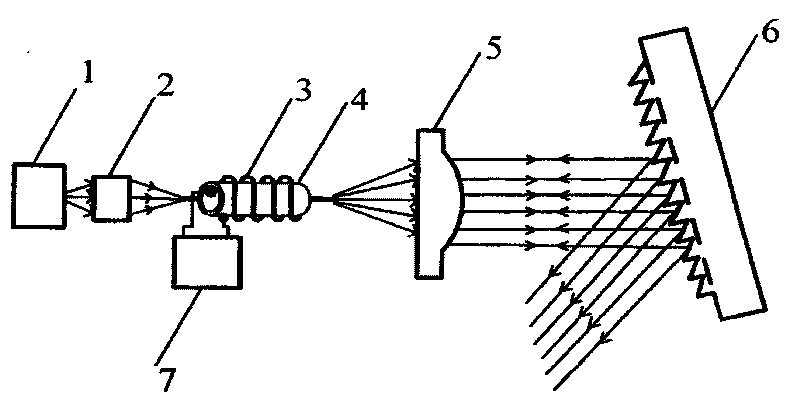

[0033] see figure 1 As shown, the present invention provides a blazed grating external cavity semiconductor laser, comprising:

[0034] A laser 1, the laser 1 is a semiconductor laser with single-ended output;

[0035] A self-focusing lens 2, the self-focusing lens 2 is located on the optical path of the laser 1;

[0036] A piezoelectric ceramic 4, the piezoelectric ceramic 4 is located on the optical path of the laser 1 behind the self-focusing lens 2, an optical fiber 3 is wound on the surface of the piezoelectric ceramic 4, the core diameter of the optical fiber 3 is greater than 50 microns, and the length is greater than 30 mm;

[0037] A collimating lens 5, which is located on the optical path of the laser 1 behind the piezoelectric ceramic 4;

[0038] The output end of the optical fiber 3 is at the object focal point of the aspheric collimator lens;

[0039] A blazed grating 6, the blazed grating 6 is located at a predetermined angle on the optical path of the laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com