Cantilever type overflow weir

An overflow weir and cantilever type technology, which is applied in the direction of distillation separation, fractionation, chemical instruments and methods, etc., can solve the problem of resonance between fluid and equipment, the influence of uniformity of flow field distribution on the tray, and the transformation of ordinary downcomers Inapplicable and other problems, to achieve the effect of improving the amplification effect, ensuring full contact mass transfer, efficient and stable mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

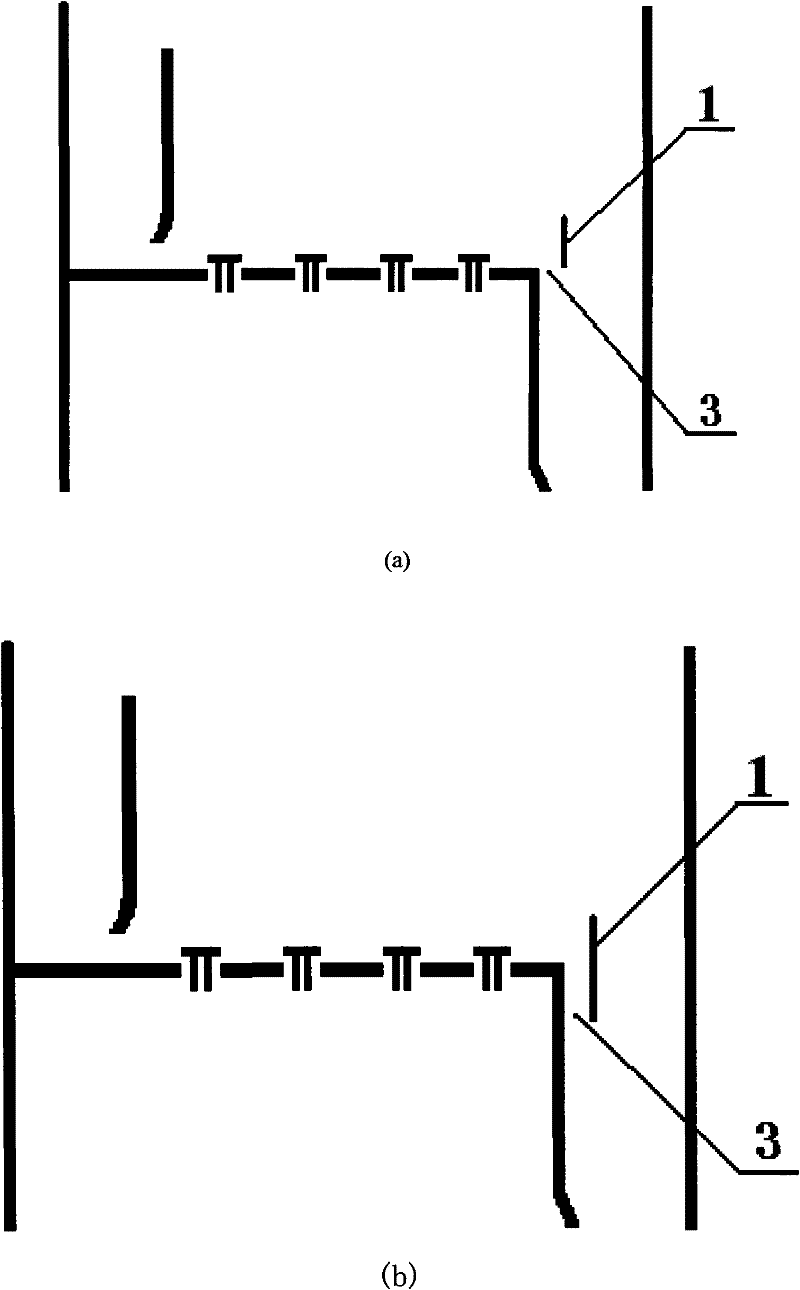

[0039] The invention relates to a cantilever overflow weir, refer to image 3 and Figure 4 As shown, it includes the weir plate 1, the cantilever 2, the tray overflow port 3 and the weir plate opening 4, and there is a strip tray overflow port 3 between the weir plate 1 and the tray outlet, and the weir plate 1 and the cantilever 2 Connected to extend into the downcomer, the weir plate 1 is provided with a weir plate opening 4 .

[0040] like image 3 As shown, the lower edge of the weir plate 1 is flush with or lower than the tray plate, and the height of the weir plate is related to the liquid flow intensity, operating pressure and upper limit of the processing capacity. The shape of the upper edge of the weir plate 1 can be straight, and can also be bow-shaped, trapezoidal, tooth-shaped or other non-straight structures, and the configuration is as follows Figure 5 shown. The weir itself of the weir plate 1 can be a straight plate, or it can be arc-shaped, bow-shaped o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com