Non-contraction tube expanding equipment

A non-shrinking, equipment technology, applied in heat exchange equipment, metal processing equipment, feeding devices, etc., can solve the problems of poor rigidity of copper pipes, low production efficiency, flanging of copper pipes, etc., and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

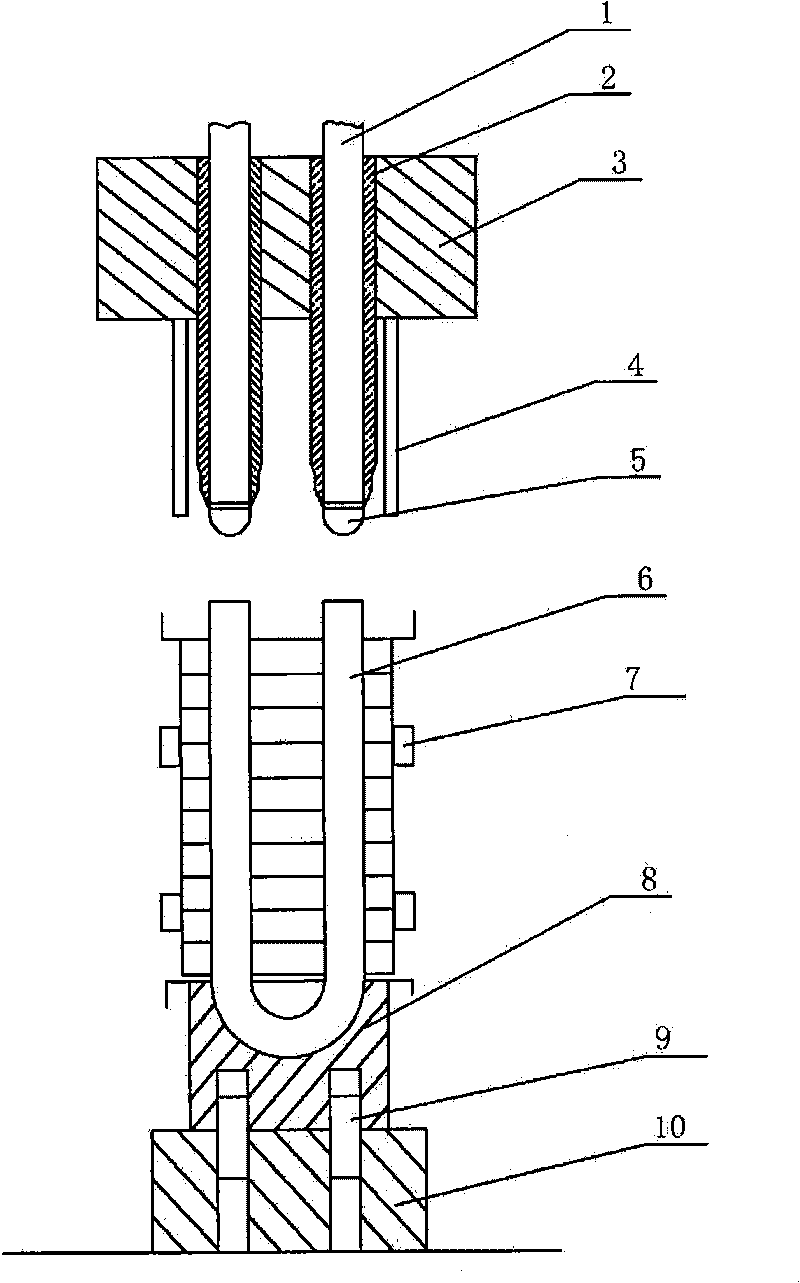

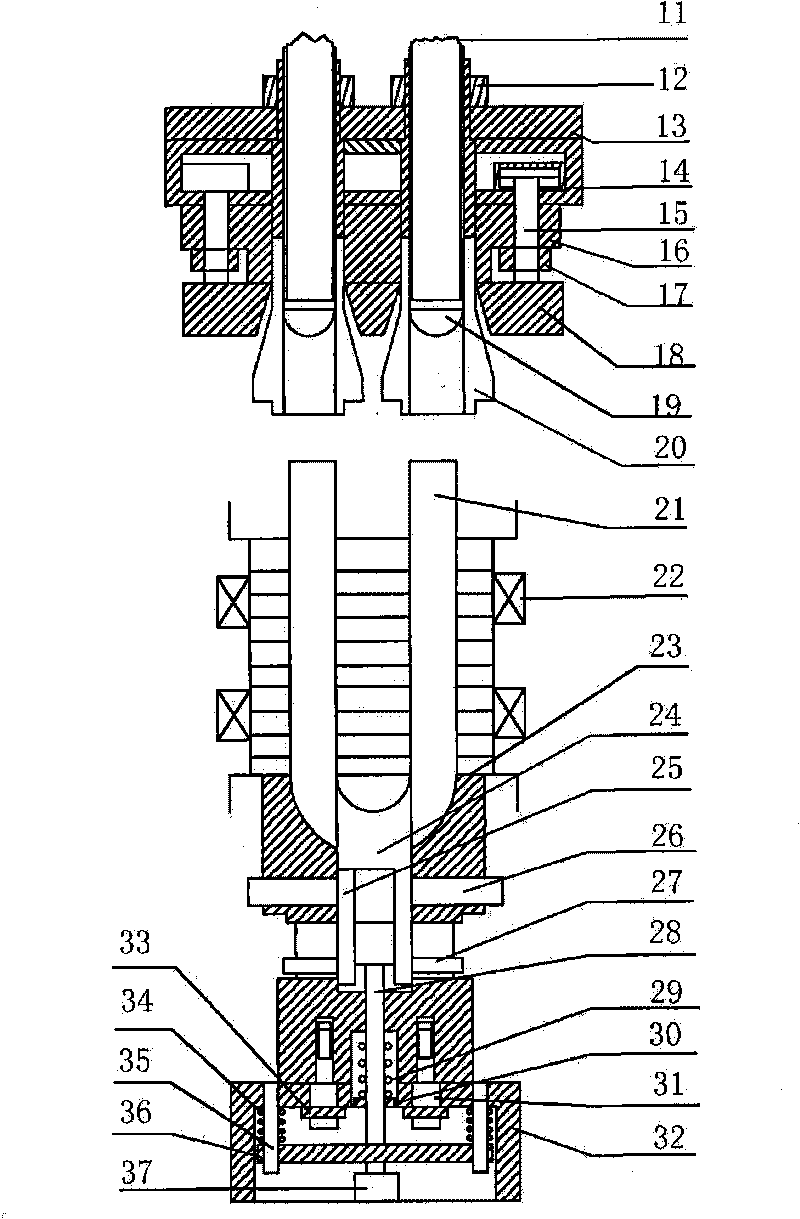

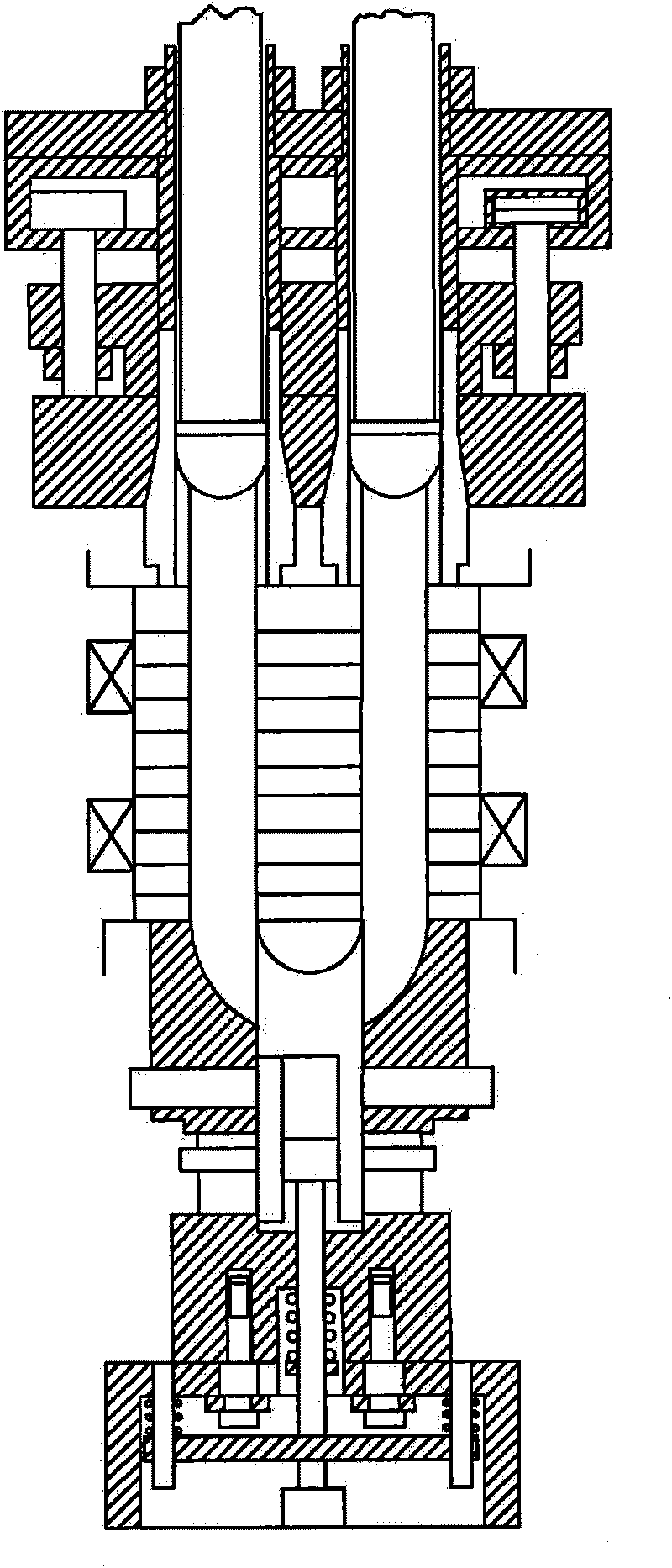

[0034] Such as figure 2 , Figure 5 As shown, a non-shrinkage tube expansion device includes a tube expander for expanding copper tubes and a belling machine for expanding copper tubes after expansion.

[0035] The tube expander of the present invention includes a lower frame for clamping workpieces and an upper frame for expanding tubes for workpieces. The upper frame includes a spring chuck 20, a taper sleeve plate 18, a movable beam 14, a fixed seat 13, a connecting seat 16, a double-acting oil cylinder 15, and an expansion rod 11, wherein the lower end of the expansion rod 11 is provided with an expansion head 19 , the outer surface of the expansion head 19 is provided with a collet 20 for clamping the two ends of the heat exchanger copper pipe workpiece 21, and the upper end of the collet 20 and the fixing seat 13 at the top of the upper frame pass through the nut 12 is fixed, the lower end is several lobes in the shape of a truncated cone, located below the vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com