Semi-slit type gating system for use in aluminium alloy sand mould casting

A sand casting and pouring system technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of inability to fill the mold according to the design, high temperature of the lower part, unqualified surface quality, etc., and solve the problem of secondary slag. , improve mechanical properties, overcome the effect of complex modeling

Inactive Publication Date: 2010-06-09

王忠仁

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although my country's aluminum alloy castings are growing rapidly with an average annual growth rate of 10%, they still cannot meet the market demand.

[0006] In the prior art, in the pouring process of the slot-type pouring system, the water in the upper and lower inner runners cannot be filled according to the design, resulting in too much molten metal entering the bottom layer, forming an unideal temperature distribution state with high temperature in the lower part, and at the same time Since the molten metal enters through the runner, the drop of the gap vertical cylinder is large, and secondary slagging is easy to occur, and the filtering facilities in the gating system cannot completely remove the generated slag, so that the castings are on the outer surface of the upper box, lower A large number of slag inclusion holes are formed on the inner surface of the box, which makes the surface quality unqualified, and seriously causes pressure leakage of container castings

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

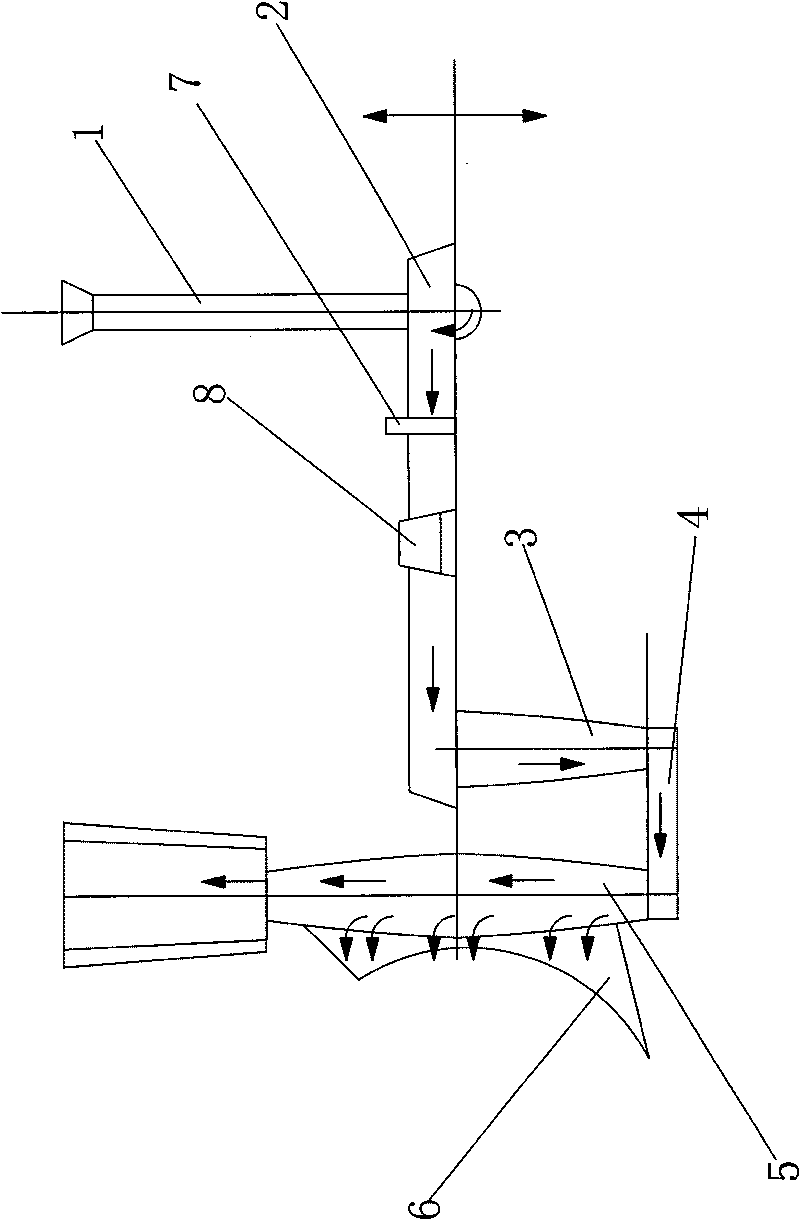

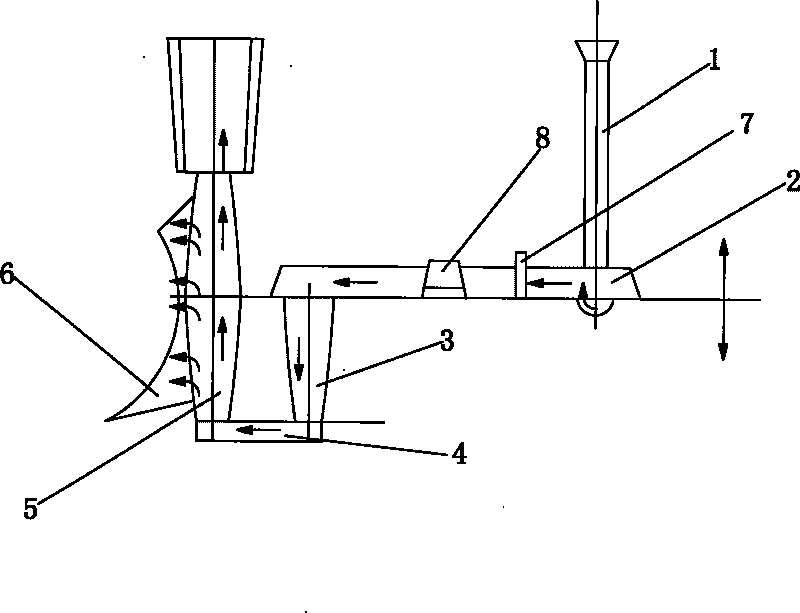

[0014] Aluminum alloy sand casting semi-slotted gating system, including sprue 1, upper runner 2, secondary sprue 3, lower runner 4, vertical tube 5, slot runner 6, upper runner 2 A filter 7 is provided at the inlet end of the molten aluminum, and an inner runner 8 is provided in the middle of the upper runner 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a semi-slit type gating system for use in aluminium alloy sand mould casting, which comprises a sprue, an upper runner, a secondary sprue, a lower runner vertical cylinder and a semi-slit type pouring gate. A smelted aluminium inlet end of the upper runner is provided with a filter and an ingate is arranged on the middle part of the upper runner. The casting system of the invention can effectively solve the problem of secondary slagging of the casting system, overcomes the shortcomings of complex shape, high labour intensity and the like, greatly improves the production efficiency, increases the casting yield to more than 97 percent from the original 70 percent in actual production and also obviously promotes the mechanical properties of upper components.

Description

technical field [0001] The invention relates to a metal casting gating system, in particular to an aluminum alloy sand casting semi-slotted gating system. Background technique [0002] Casting is a highly practical application technology combining science and practice. In many fields, such as high-end technical products such as aerospace, automobile industry, ships, vehicles and various machinery manufacturing, the development of advanced equipment is often hindered due to unqualified castings, which seriously restricts the development of society. [0003] Our ancestors had world-leading bronze casting technology (Simuwu Dafang Ding) as early as the Shang and Zhou Dynasties, which has become the pride of our Chinese descendants. The "Great Bell of Yongle" in the modern Ming Dynasty also amazed people all over the world! This is the immortal contribution made by our ancestors to the development of world civilization. So far, people have not been able to detect the mystery ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22C9/02

Inventor 王忠仁

Owner 王忠仁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com