Double-channel grinding method of double-row ball bearing

A double-row ball bearing and double-channel technology, applied in the field of mechanical processing, can solve the problems of many reworked products, low matching rate and high production cost, and achieve high product matching rate, wide application range and good product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

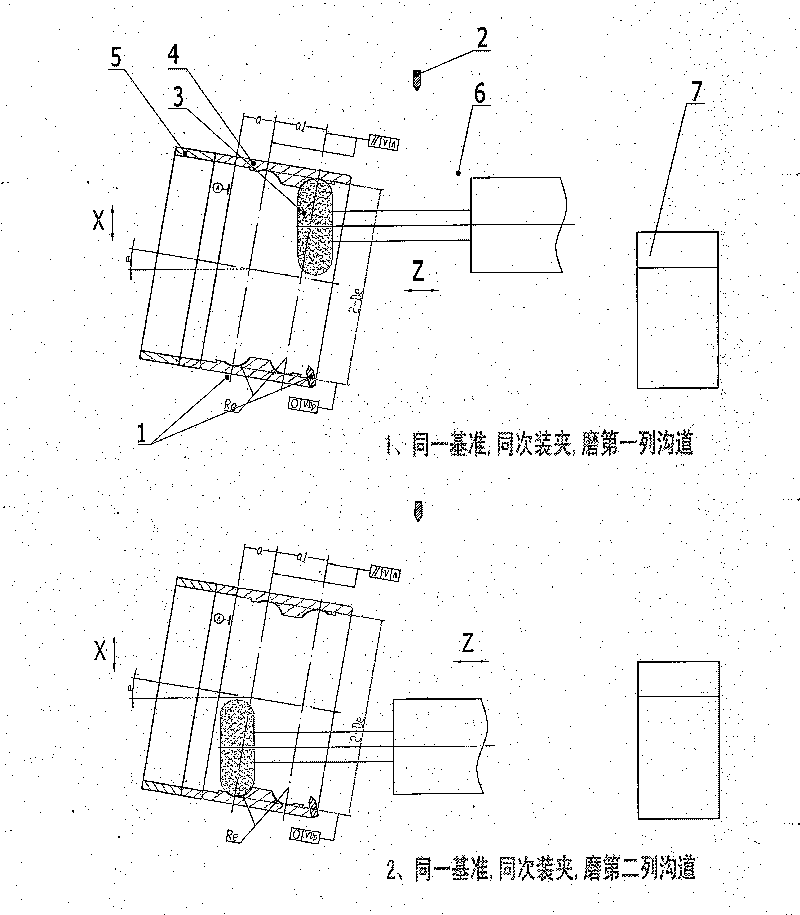

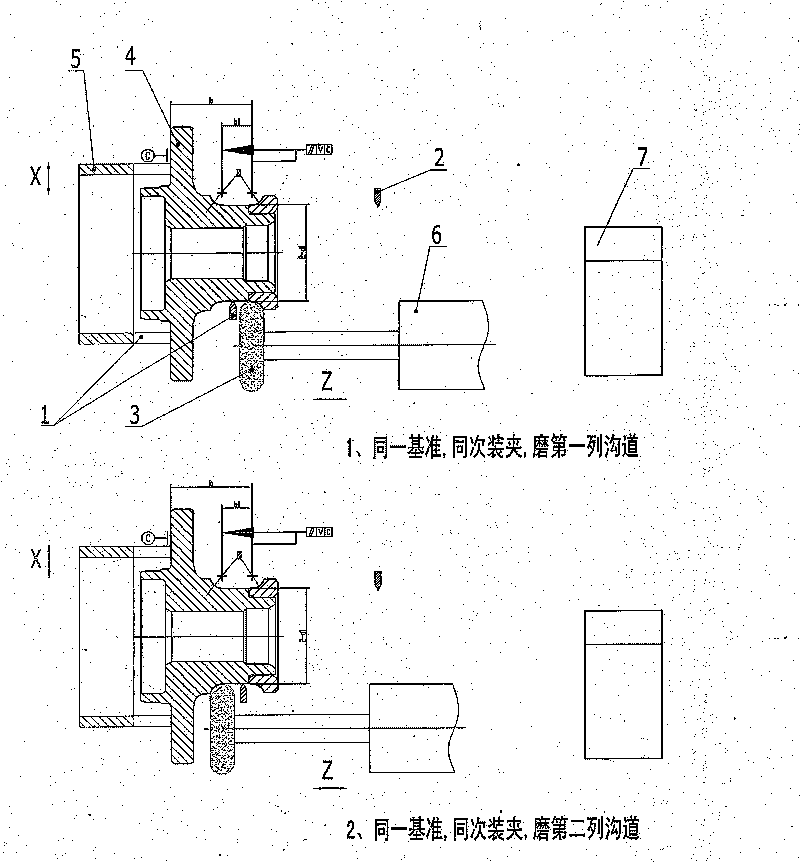

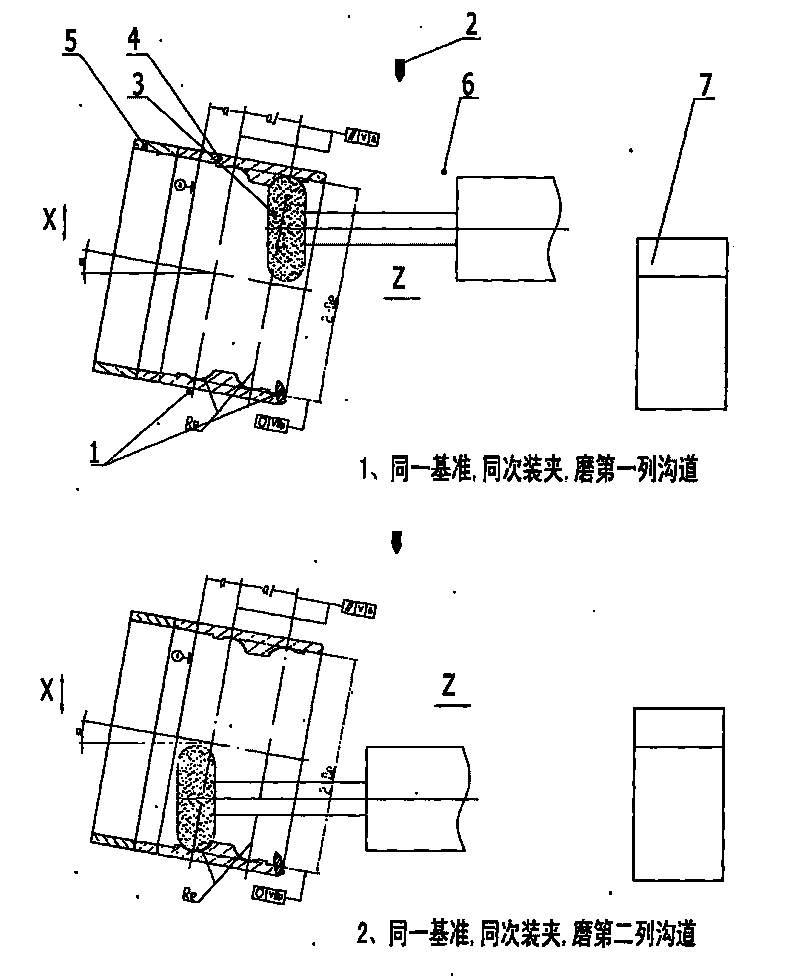

[0010] refer to figure 1 1. The method for grinding the groove of the inner ring of the automobile angular contact ball hub bearing in this embodiment includes a centerless fixture 1, an arc dresser 2, a grinding wheel 3, a double-channel ferrule to be ground 4, an equipment workpiece holder 5, and an electric spindle 6 and control cabinet 7.

[0011] The centerless fixture is composed of an axial positioning support and two radial supports. The runout of the end face of the axial positioning support is controlled within 2 μm.

[0012] The ground double-channel ferrule is the grinding process of the double-row angular contact ball bearing outer ring, the double-row deep groove ball bearing inner and outer ring double-channel grinding, and the third-generation automobile hub bearing inner ring and flange sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com