Die-pressing membrane filter plate and molding method thereof

A diaphragm filter plate and filter plate technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as shortened life, broken diaphragm filter plate core, and insufficient diaphragm density to achieve increased service life , Reliable sealing performance, good effect on tympanic membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

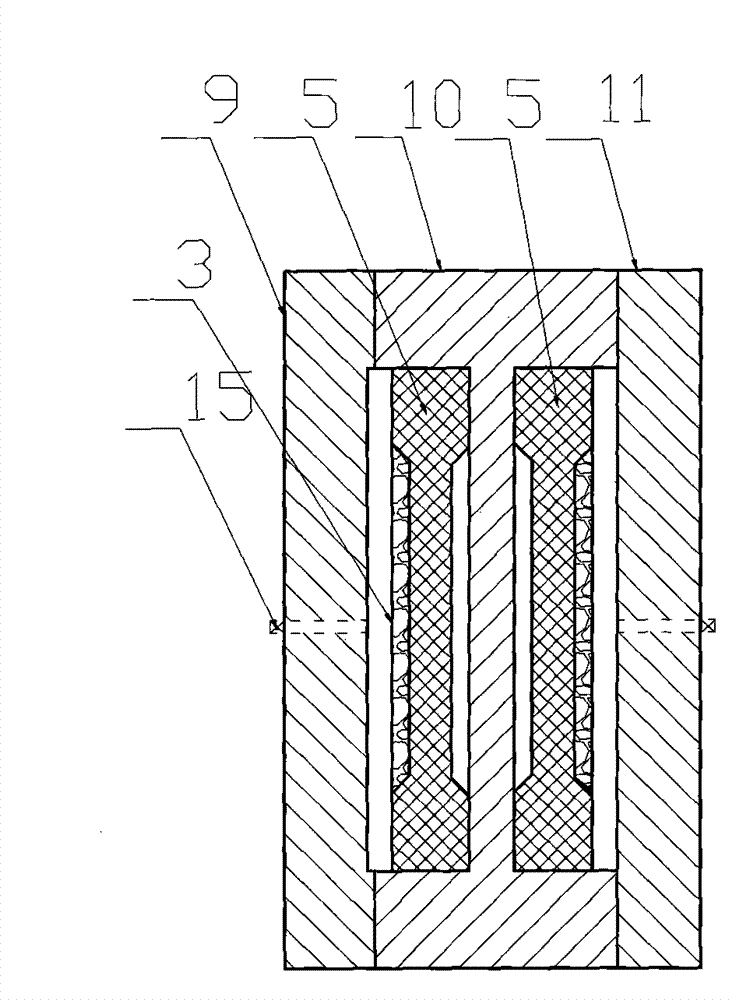

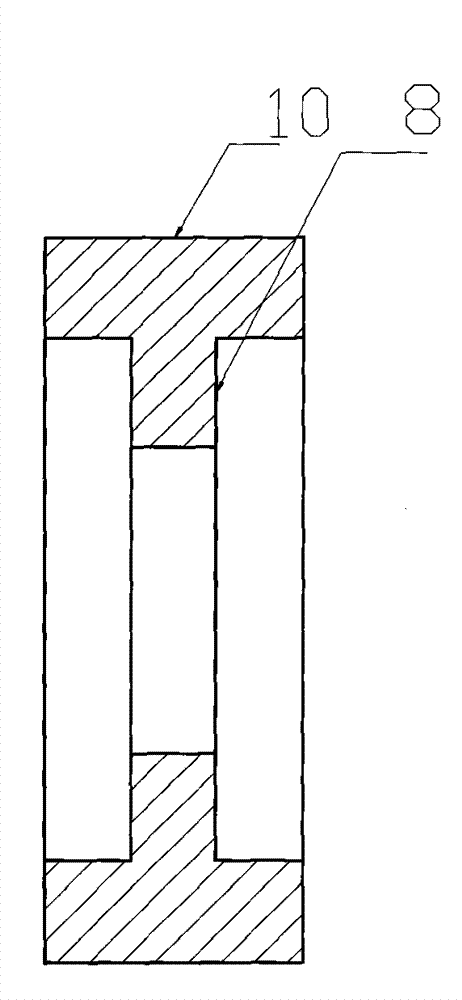

[0010] Embodiment 1: with reference to attached figure 1 and 2 . Molded diaphragm filter plate molding die is made of left mold 9 and middle mold 10 and right mold 11, and the making of left mold 9 and right mold 11 (two upper molds) is prior art, is not described here. The middle mold 10 is a double mold frame structure, and its manufacturing technology and process are prior art, and will not be described here. Two filter plate cores 5 are respectively located in the double mold frame of the middle mold 10 and can be taken out. The faces of the two filter plate cores 5 are respectively the mold surfaces of the left and right molds 8 and 11, and the mold faces of the left and right molds 8 and 11. The cavity is a diaphragm forming cavity 3 . The left and right molds 9 and 11 are provided with one or two or more feeding ports 2, and the feeding ports are provided with extrusion plates 4 that match the feeding ports. Two or more extrusion plates 4 are placed in the extrusion ...

Embodiment 2

[0011] Embodiment 2: on the basis of embodiment 1, the left and right molds 9 and 11 are not provided with feeding ports and adopt extruding equipment (mechanism), such as oil press or hydraulic press directly left, mold and middle mold clamping, thereby will The plasticized (molten) plastic located in the cavity is extruded to various parts of the cavity.

Embodiment 3

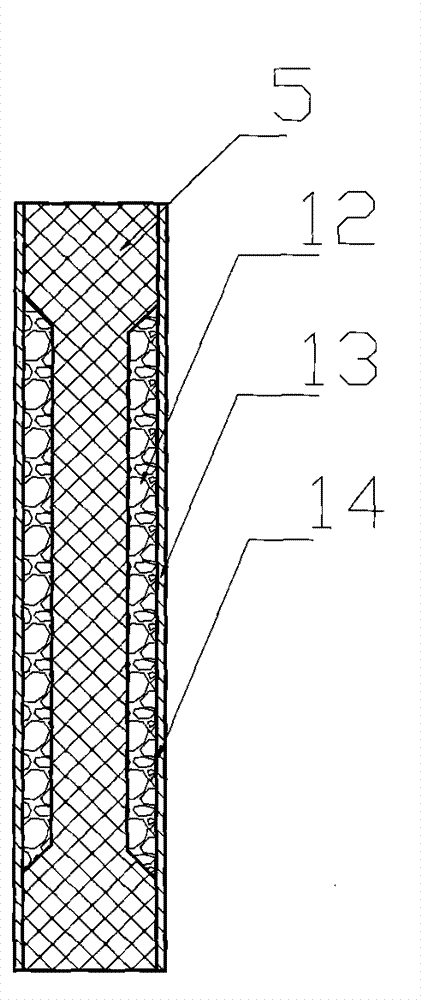

[0012] Embodiment 3: on the basis of embodiment 1 or 2, or on the basis of 1 and 2, the compression molding method of molded diaphragm filter plate, it comprises filter plate core, two filter plate cores are put into the double mold frame, The tympanic surface of the filter plate core is equipped with a degradable mold core, put the plastic mass on the tympanic surface of the two filter plate cores, then close the two left and right molds with the middle mold, and form two pieces after cooling Single-sided plastic diaphragm filter plates, then turn the two single-sided plastic diaphragm filter plates over and put them into the double mold frame. There is a degradable mold core on the tympanic membrane surface of the filter plate core, and put the plasticized plastic group into the On the surface of the tympanic membrane of the filter plate core, the left and right molds are molded with the middle mold, and after cooling, two double-sided plastic diaphragm filter plates are form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com