Method for oil extraction by means of air injection and low-temperature oxidation and experiment device

An experimental device and air injection technology, which is applied in the direction of fluid extraction, earthwork drilling, wellbore/well components, etc., can solve the problems of low recovery rate and high investment, and achieve the effect of simple structure and flexible disassembly of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

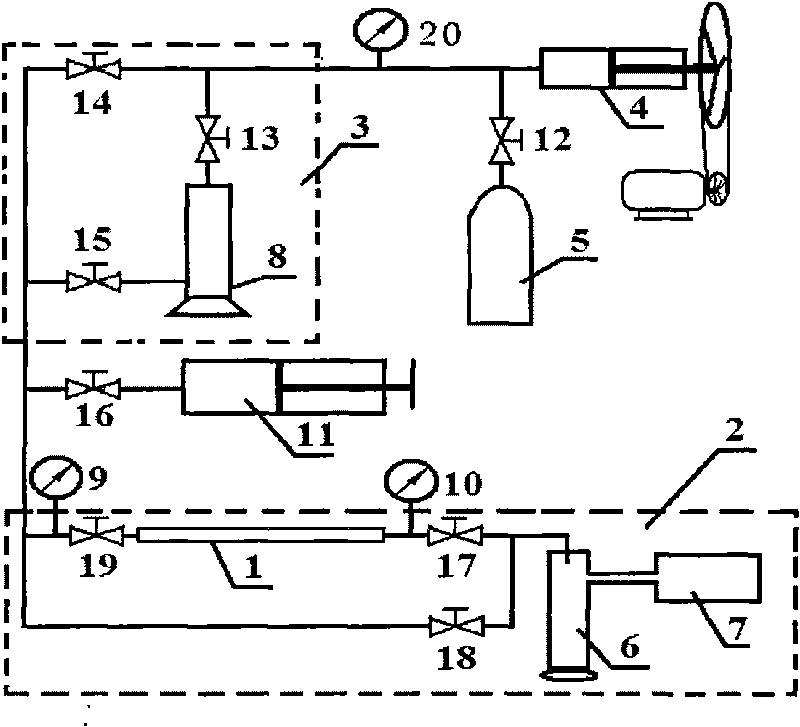

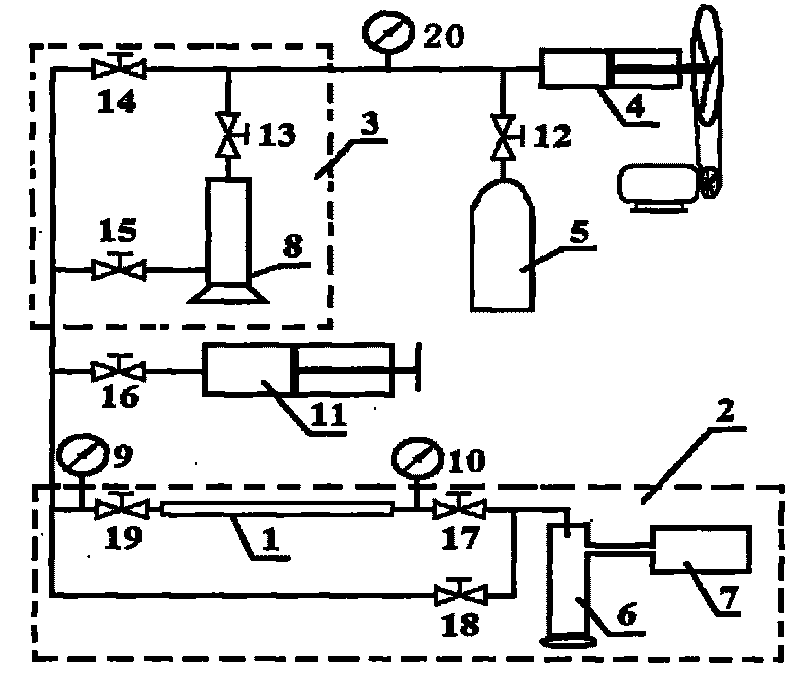

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] see figure 1 .

[0014] An experimental device used in the method of air injection low-temperature oxidation oil recovery, mainly composed of a core or sand filling model 1, a constant temperature air bath 2, 3, an intermediate container 8, a booster 4, a liquid sampler 11, an oil-gas separator 6 and The tail gas receiver 7 and other parts are characterized in that: the core or sand filling model 1 is connected to the supercharger 4, the intermediate container 8 and the liquid sampler 11 through different valves, and the other end of the intermediate container 8 is connected to the supercharger 4 , the two ends of the core or sand packing model 1 are connected with the oil-gas separator 6 at the same time.

[0015] The present invention is provided with valves at the connecting parts of the core or sand filling model 1, constant temperature air baths 2 and 3, inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com