Backlight module and display device using same

A technology for a backlight module and a display device, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of burning brightness, short circuit and deformation of light-emitting diodes 130, avoid abnormal display, and improve assembly yield. , the effect of preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are specifically cited below and described in detail with accompanying drawings.

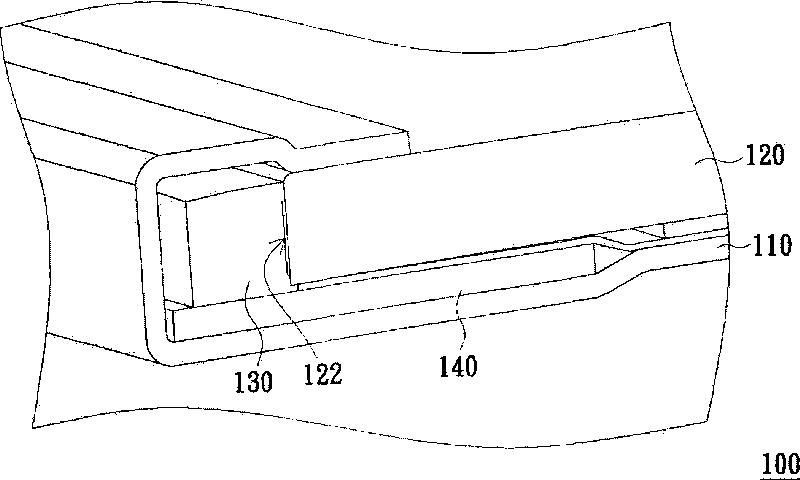

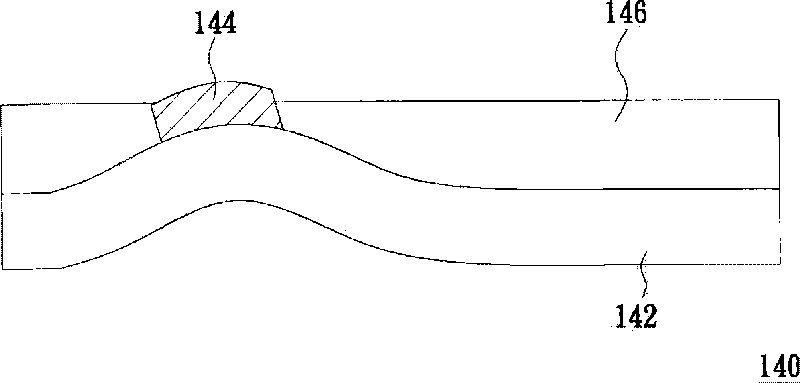

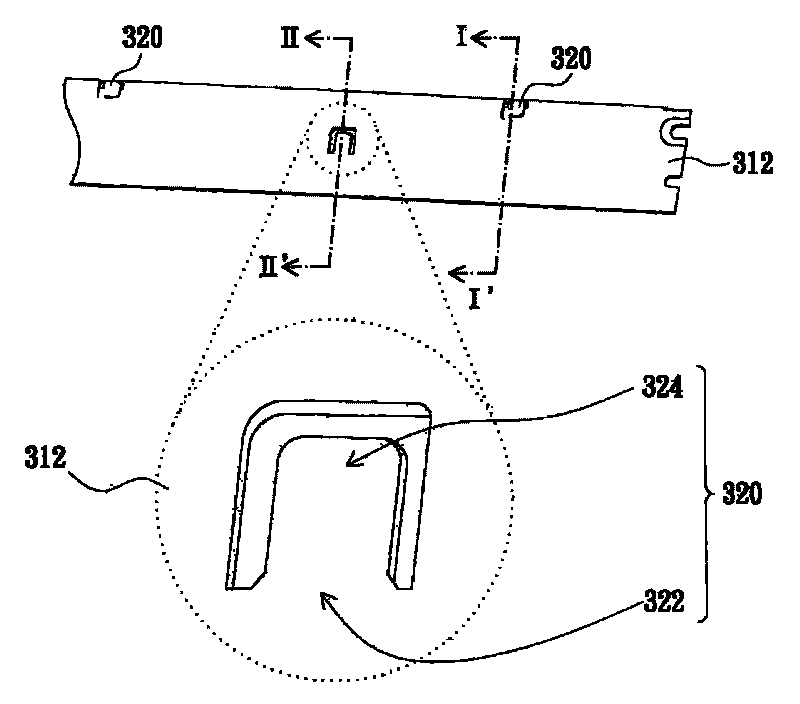

[0062] Figure 3A It is a schematic diagram of the back of the backlight module in an embodiment of the present invention, Figure 3B for Figure 3A The cross-sectional schematic diagram of the backlight module along the line I-I', Figure 3C then Figure 3A The schematic cross-sectional view of the backlight module along the line II-II'. Please refer to Figure 3A and Figure 3B, the backlight module 300 includes a frame 310 , a plurality of protrusion structures 320 , a light guide plate 330 , a circuit board 340 and a plurality of light emitting diodes 350 . The frame 310 is made of metal material, for example, and it includes a bottom 312, a connection portion 314 and an extension portion 316, wherein the bottom 312 has an upper surface 311, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com