Mobile lifting combined measuring point frame device

A measuring point and frame technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of lack of appearance quality of the frame, unstable suspension of the measuring point, waste of artificial materials, etc., so as to reduce the waste of labor and materials, meet the measurement requirements and operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

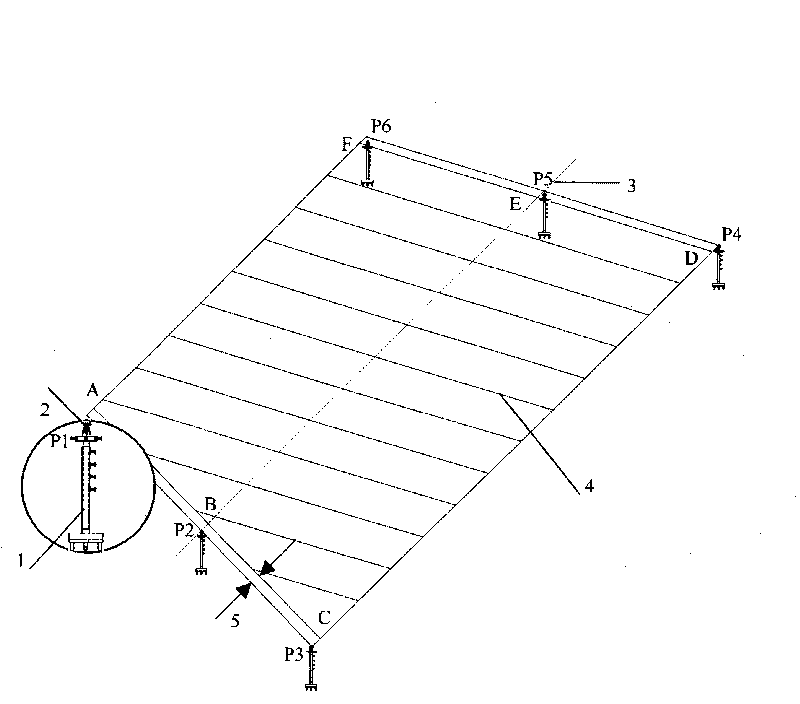

[0020] Such as figure 1 As shown, a measurement schematic diagram of a mobile elevating combined measuring point frame device, the described a kind of mobile elevating combined measuring point frame device includes 6 moving elevating frame 1 and 1 vertical measuring point frame 2, the vertical measuring point frame 2 are respectively placed on 6 mobile elevating frames 1.

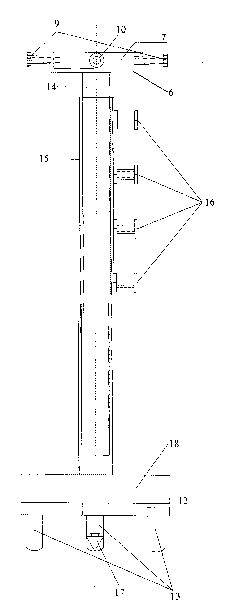

[0021] Such as figure 2 As shown, it is a schematic diagram of the front view of the mobile elevating frame structure. Three support columns 13 are arranged on the lower plane of the base circular plate 12; The inner sleeve 14 is adjusted and fastened by four lifting fastening screws 16 arranged on the outer sleeve 15 , and the lower plane of the concave tray 6 is connected with the upper top end of the inner sleeve 14 .

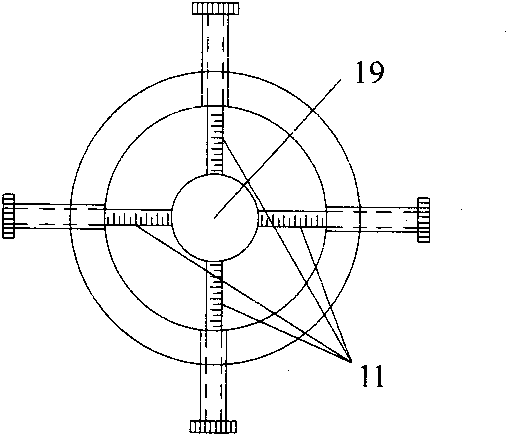

[0022] Such as image 3 As shown, it is a schematic diagram of a top view of the concave tray structure. The center of the concave tray 6 is provided with a central through hole 19 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com