Self-adapted temperature sensor of gas range

A technology for temperature sensors and gas stoves, applied in thermometers, thermometer parts, thermometers with direct heat-sensitive electric/magnetic elements, etc., can solve the limitation of temperature measurement points, low temperature measurement accuracy, misoperation, etc. problems, to achieve the effects of strong fire and heat insulation capabilities, accurate temperature transmission, and high temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

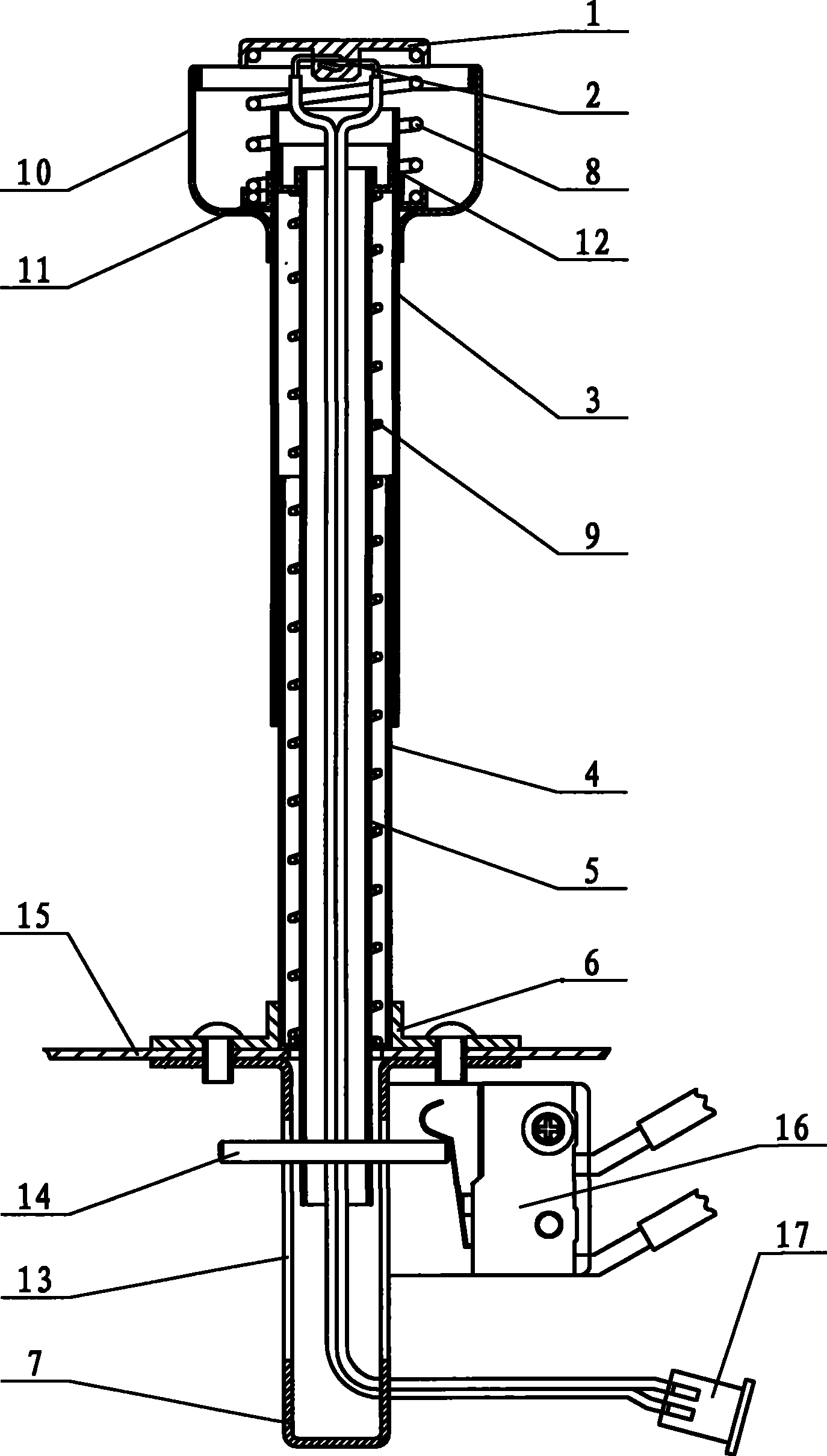

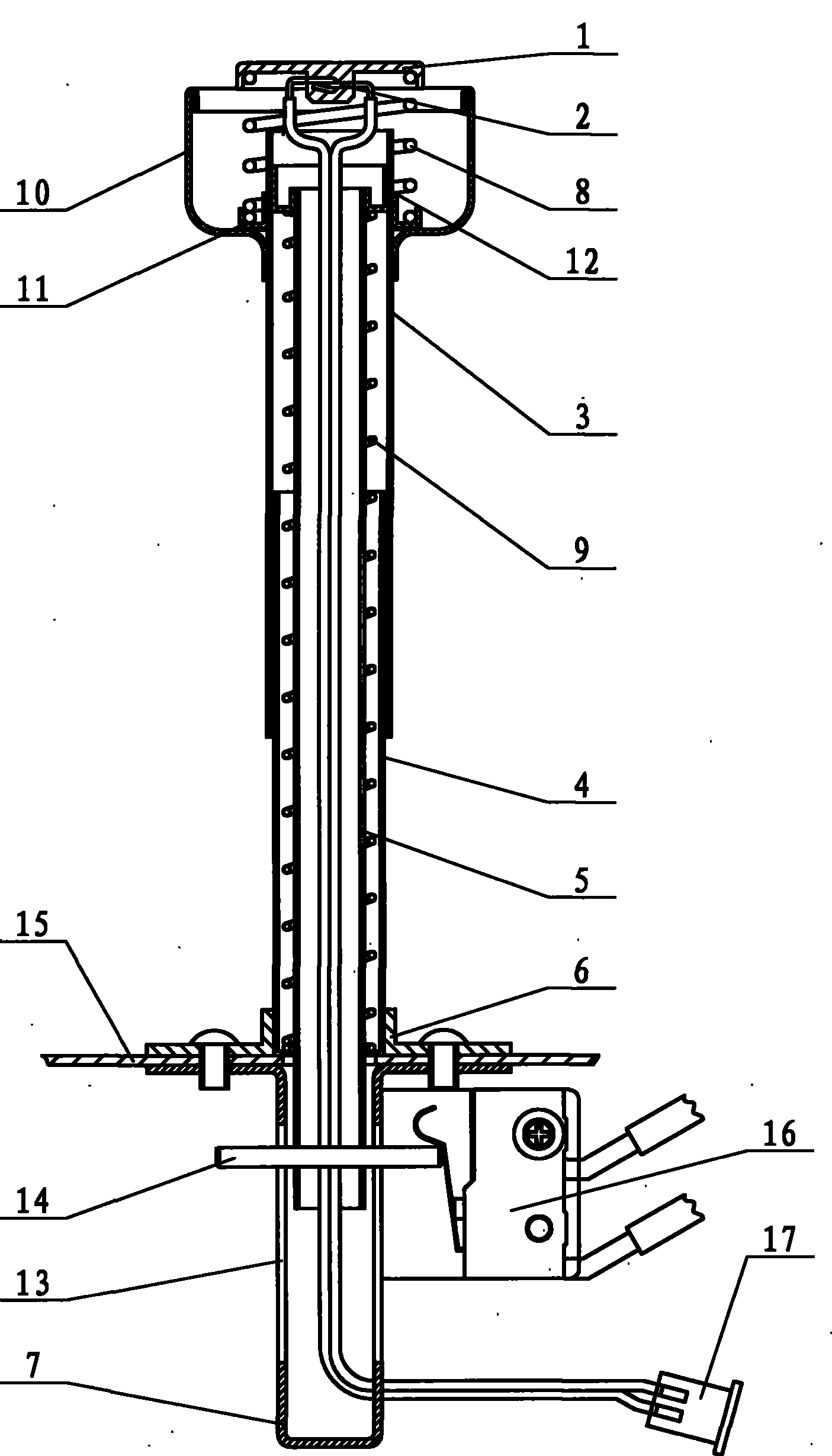

[0012] like figure 1 As shown, the adaptive temperature sensor of the gas cooker of the present invention includes a sensing cap 1, a thermocouple 2, a sliding sleeve 3, a guide sleeve 4, a guide rod 5, a positioning plate 6, a spring one 8, a spring two 9 and a guide frame 7 , the outer ring surface of the upper end of the sliding sleeve 3 is fixedly connected with a positioning ring 11 and a fireproof ring 10, the positioning ring 11 is installed in the fireproof ring 10, the inner ring surface of the upper end of the sliding sleeve 3 is fixedly connected with a positioning ring 2 12, and the guide rod 5 is A straight round pipe, the outer ring surface of its upper end is fixedly connected with the positioning ring 2 12, the lower end of the guide rod 5 is fixed with a shaft pin 14, the lower end of the guide sleeve 4 is fixedly connected with the positioning plate 6, and the spring 2 9 is installed in the guide sleeve 4 and set Hold the guide rod 5, its upper end is against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com