Method for digesting total iron in water sample

A water sample and standard water sample technology, applied in the preparation of test samples, thermal stimulation analysis, material stimulation analysis, etc., can solve the problems of long digestion time, incomplete digestion of samples, cross-contamination, etc., and reach the pretreatment cycle Effects of shortening, health benefits, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

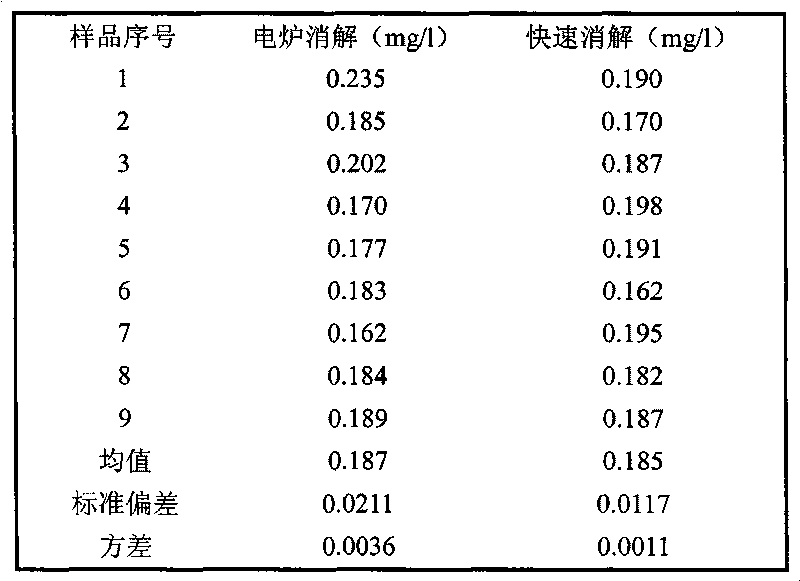

[0017] A water sample total iron digestion method, which uses a sealed, pressure-resistant, temperature-resistant glass reagent bottle, takes a certain volume of water sample, adds an appropriate amount of nitric acid, and the nitric acid does not exceed 5% of the total volume, at 130-150 Heat and digest at ℃, the digested water sample is in a sub-boiling state, and the digestion time is about 20-30 minutes, and the sample is free of turbidity. After standing and cooling, the supernatant is measured by a plasma emission spectrometer. The nitric acid in this embodiment is mixed with water in a ratio of 3:1, the digestion temperature is 138-142° C., and the digestion time is 27 minutes.

[0018] The invention has a wide range of applications and can be applied to drinking water, industrial circulating water, waste water and other water bodies.

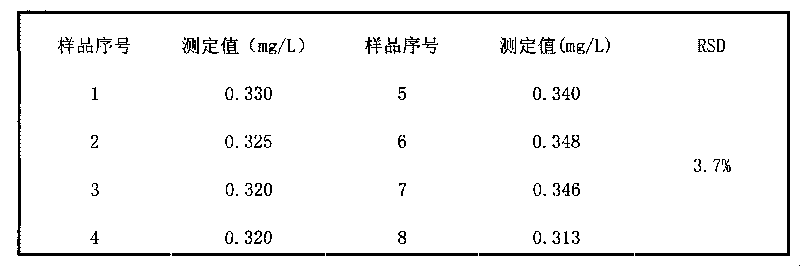

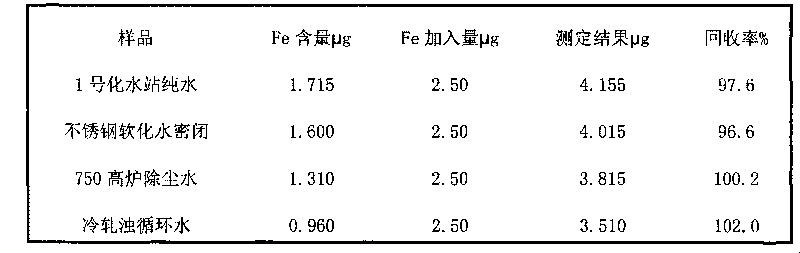

[0019] Precision measurement: take the same volume of water samples from the same sample, pretreat with the above method, and the analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com