Combustible gas explosion experiment system

A gas explosion and experimental system technology, applied in the field of experimental systems, can solve the problems of complex operation procedures, high cost, and high airtightness requirements, and achieve the effects of simple operation, low cost, and favorable data acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

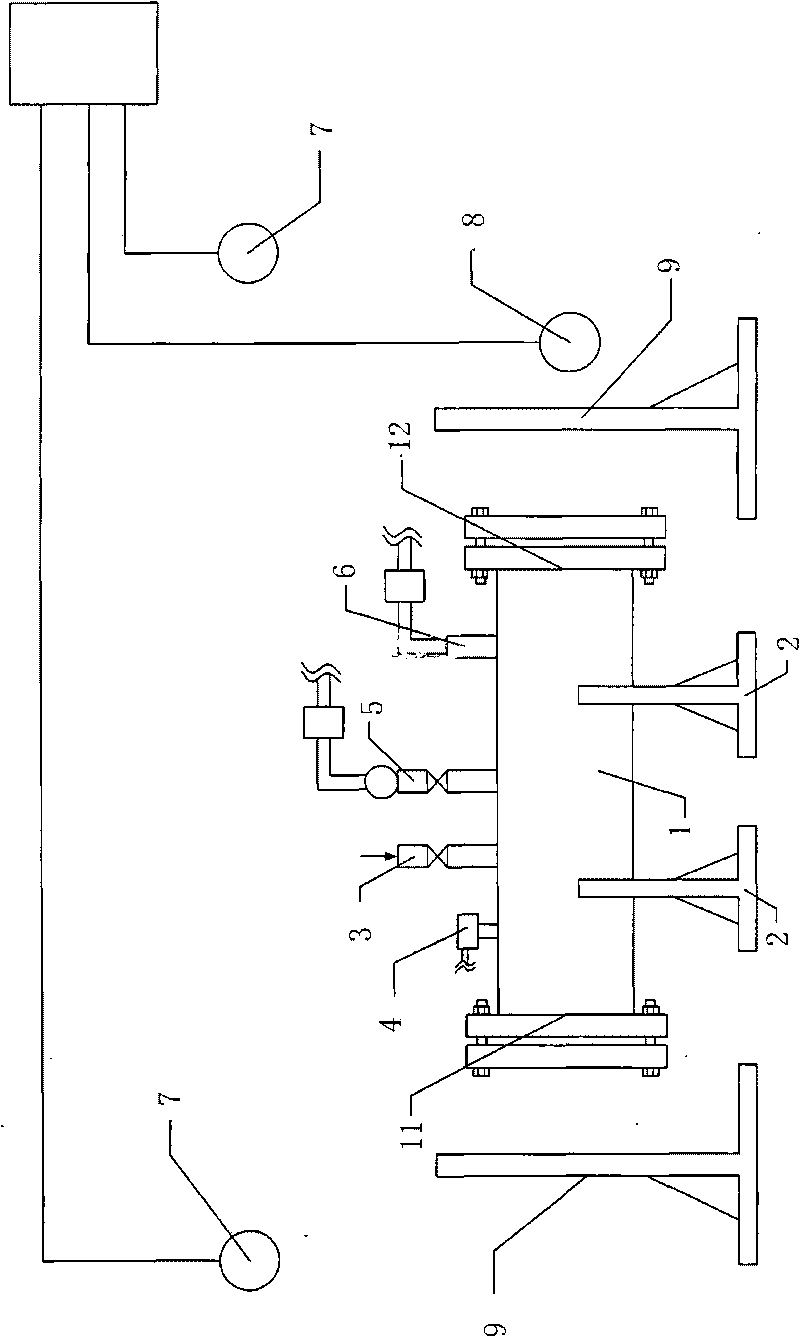

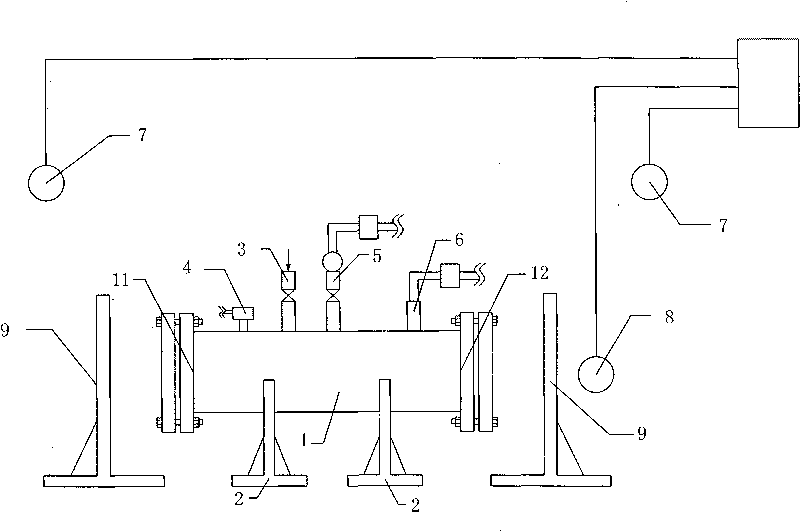

[0014] With reference to accompanying drawing, further illustrate the present invention:

[0015] The combustible gas explosion test system includes a tubular explosion test cylinder 1, the explosion test cylinder 1 is horizontally erected on a support 2, and the front opening 11 and the rear end opening 12 of the explosion test cylinder 1 are provided with openings Sealed explosion-proof membrane; the explosion test tube 1 is connected to a gas supply device 3 that injects combustible gas at normal temperature and pressure into the inner cavity of the tube, and the explosion test tube 1 is provided with a pressure sensor 4 for sensing the internal pressure of the tube. A monitor 5 for monitoring the concentration of combustible gas in the cylinder and an igniter 6 for igniting the gas in the cylinder, and the pressure sensor 4 is connected with a display module for displaying the pressure value in the cylinder.

[0016] A camera 7 for recording the explosion and a listener 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com