Drive circuit of light source

A light source driving circuit and current value technology, applied in the direction of instruments, static indicators, etc., can solve the problems of reducing the service life of the backlight module and increasing power consumption, and achieve the effects of reducing system cost, increasing maximum brightness, and increasing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Before describing the spirit of the present invention with the embodiments, it is first assumed that the light source driving circuit listed in each embodiment is applicable to a backlight module. In addition, the light source driving circuit described in each embodiment is further used to drive a plurality of light-emitting components (not shown) arranged in the backlight module, so that the light-emitting components generate light. Wherein, the light-emitting components may respectively be composed of a light-emitting diode. However, the above assumptions are not intended to limit the present invention, and those skilled in the art can also change the application type of the light source driving circuit according to the spirit of the present invention.

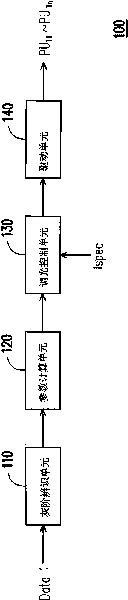

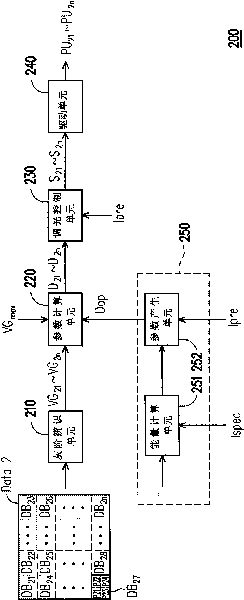

[0029] Figure 2A It is a circuit structure diagram of a light source driving circuit according to an embodiment of the present invention. refer to Figure 2A The light source driving circuit 200 includes a graysca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com