Coating length measuring device

A length measurement and coating technology, applied in the field of coating length measurement devices, can solve the problems of measurement error, inaccurate measurement data, and the inability of optical fiber sensors to obtain accurate coating or interval edge information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

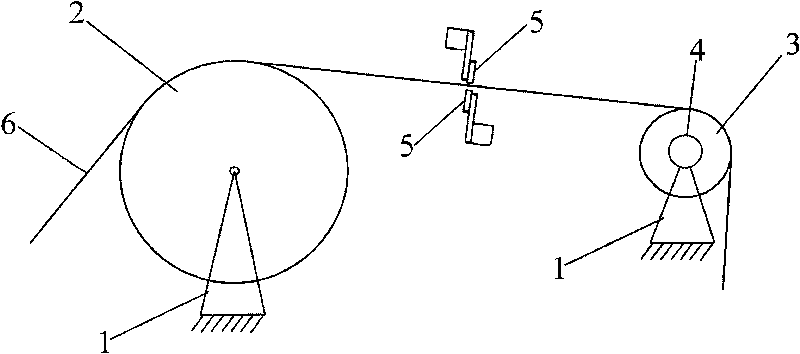

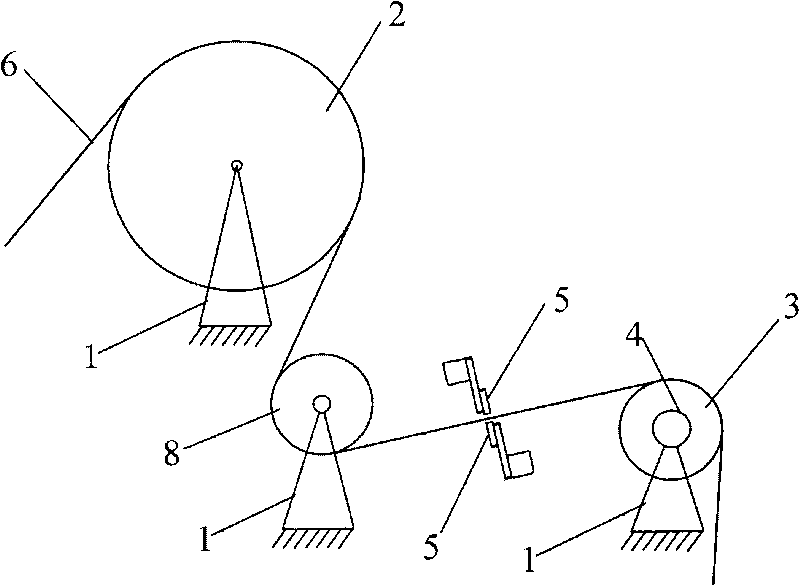

[0021] Such as figure 1 with figure 2 As shown, the present invention provides an embodiment of a coating length measuring device.

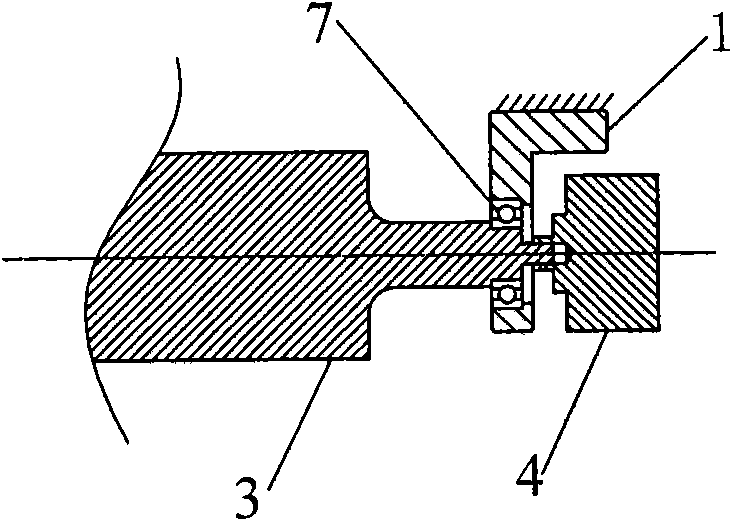

[0022] The coating length measurement device is used to measure the coating or / and interval of the pole piece 6 and the alignment length of the front and back sides, and it includes: a support 1 and discharge rubber rollers 2 that are rotatably connected with the support 1 and are parallel to each other, The first roller 3, two linear optical fiber sensors 5 are oppositely arranged between the discharge rubber roller 2 and the first roller 3, and the output end of the linear optical fiber sensor 5 is connected to the processor (not shown in the accompanying drawings) The signal input end of the described coating length measurement device also includes a rotary encoder 4 coaxially connected with the rotating shaft of the first roller 3, and the rotary encoder 4 is electrically connected to the signal input end of the processor. connect. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com