Box shifting mechanism matched with row spacing adjustable transplanter

The technology of a box-moving mechanism and a rice transplanter is applied in the fields of agricultural machinery and rice transplanters, which can solve the problems of the adjustable stroke of the rice transplanter and the inability to meet actual needs, etc., and achieves the effects of simple structure, easy replacement and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

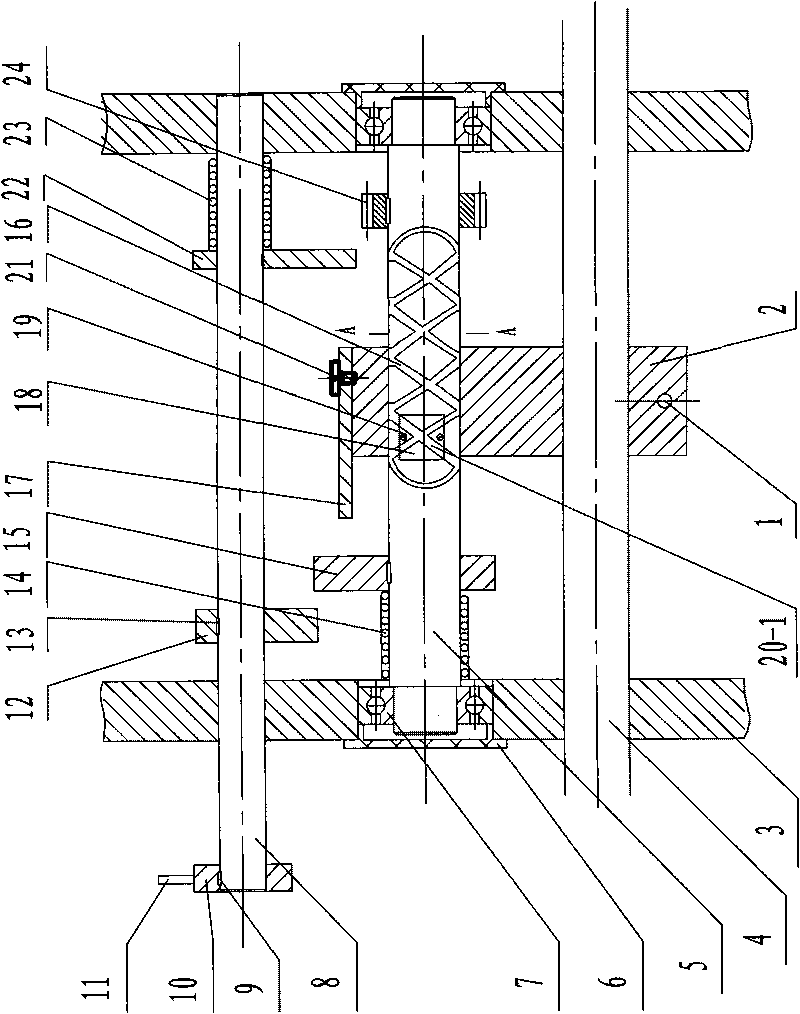

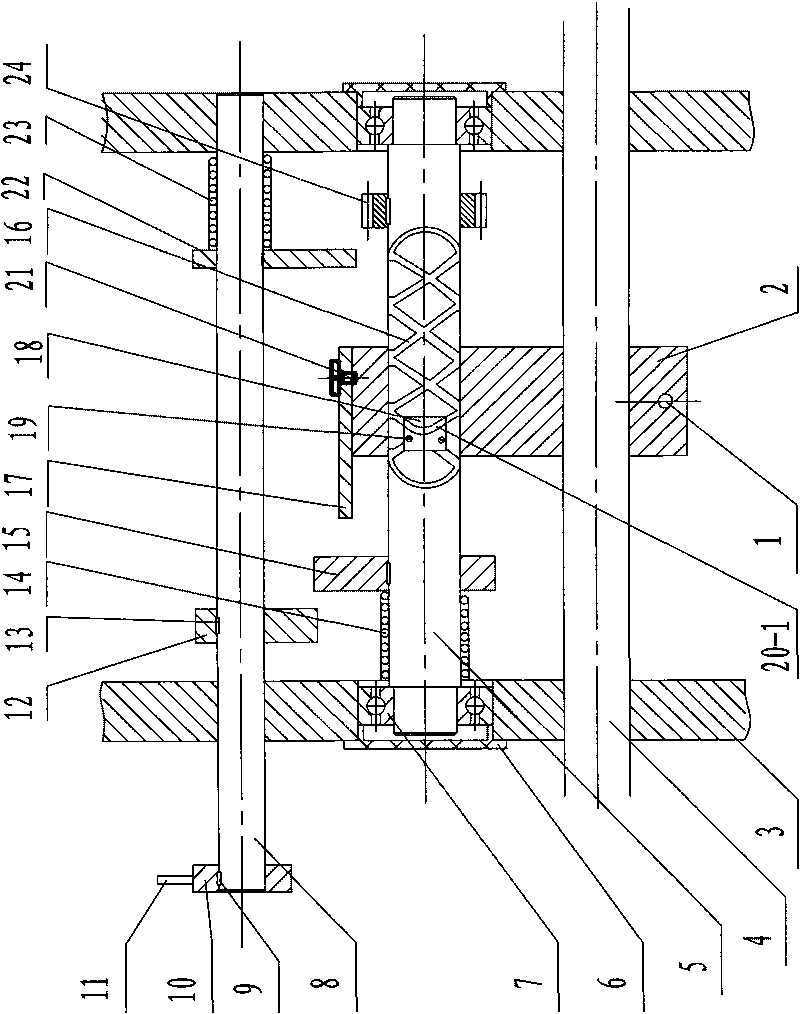

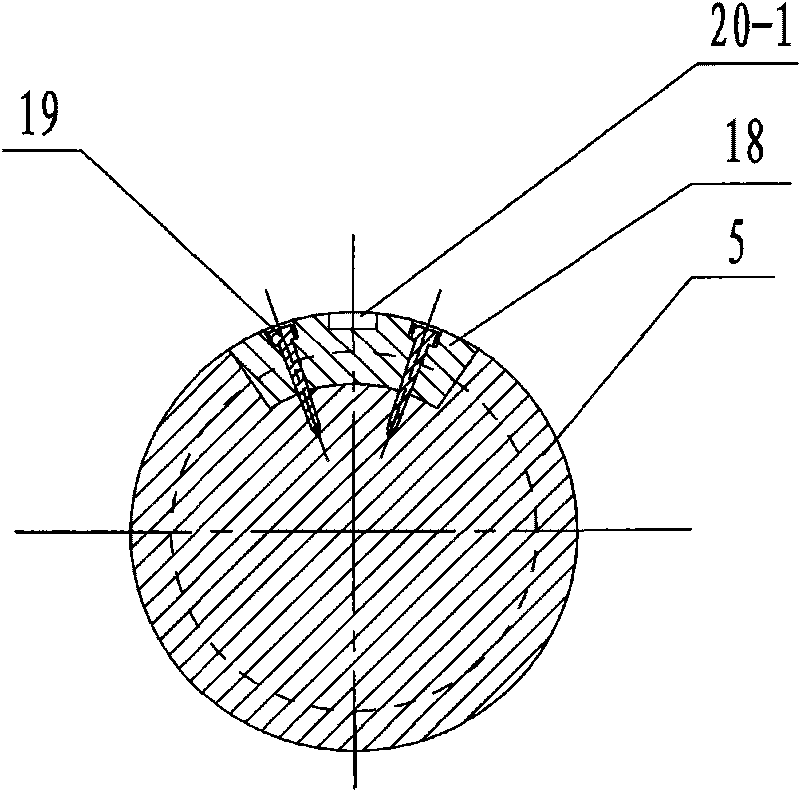

[0014] Such as figure 1 Shown, the present invention is by moving box bar pin 1, transmission nut 2, casing 3, box moving bar 4, transmission screw 5, bearing gland 6, bearing 7, vertically send seedling bar 8, vertically send seedling cover 10, Longitudinal seedling sending arm 11, longitudinal seedling sending passive cam 12, spring 14, longitudinal seedling sending active cam 15, extension plate 17, extension plate connecting screw 21, longitudinal seedling sending bar baffle plate 22, spring 23 power input gear 24 and other components.

[0015] On the box body 3, the box moving rod 4, the transmission screw rod 5 and the longitudinal seedling feeding rod 8 are respectively supported in parallel, and the transmission screw rod 5 in the box body 3 is provided with two sets of thread grooves 16 with opposite phases and continuous at both ends. , on the transmission screw 16, the transmission nut 2 that is threadedly connected with the two groups of thread grooves 16 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com