Rotating guide tube spouted-bed grain dryer for removing resistance, adjusting distance and filling air

A technology of grain drying and spouted bed, which is applied in the drying field of rice, bulk grain barley, wheat, soybean and corn. Large air volume and other issues, to achieve the effect of ensuring the ring gap to supplement the hot air, optimizing the drying performance and operating performance, and eliminating the starting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A specific implementation manner of the present invention is provided below.

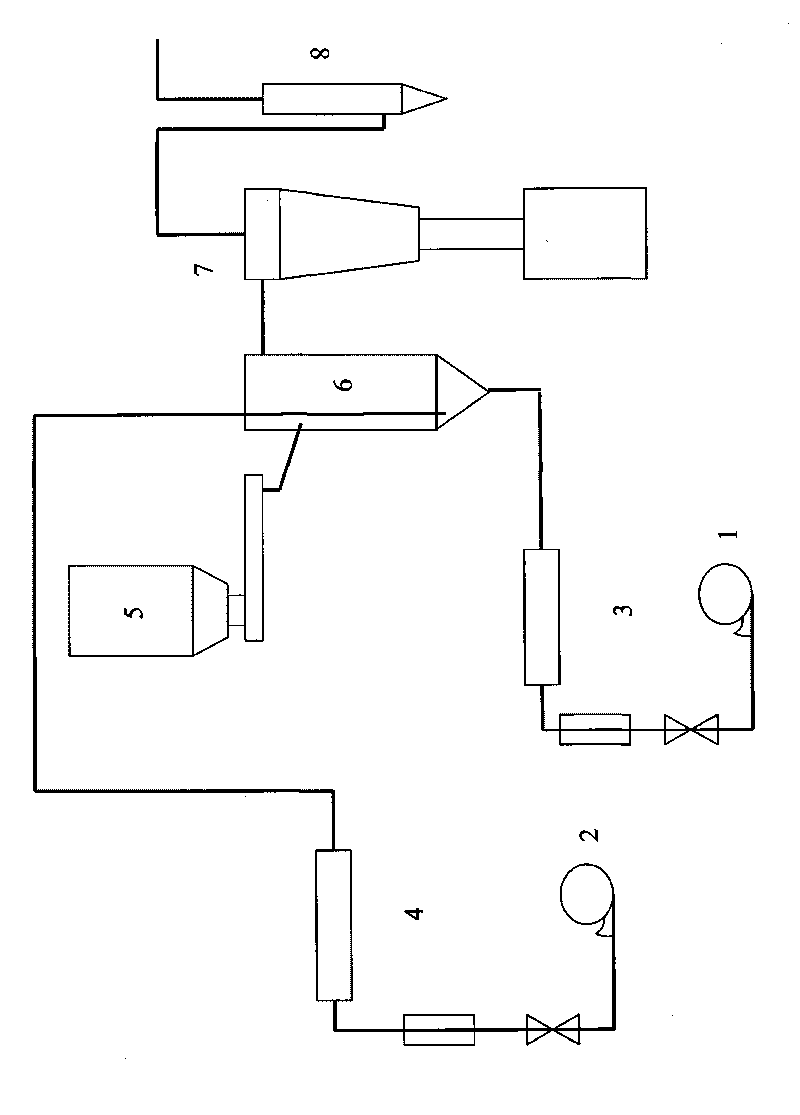

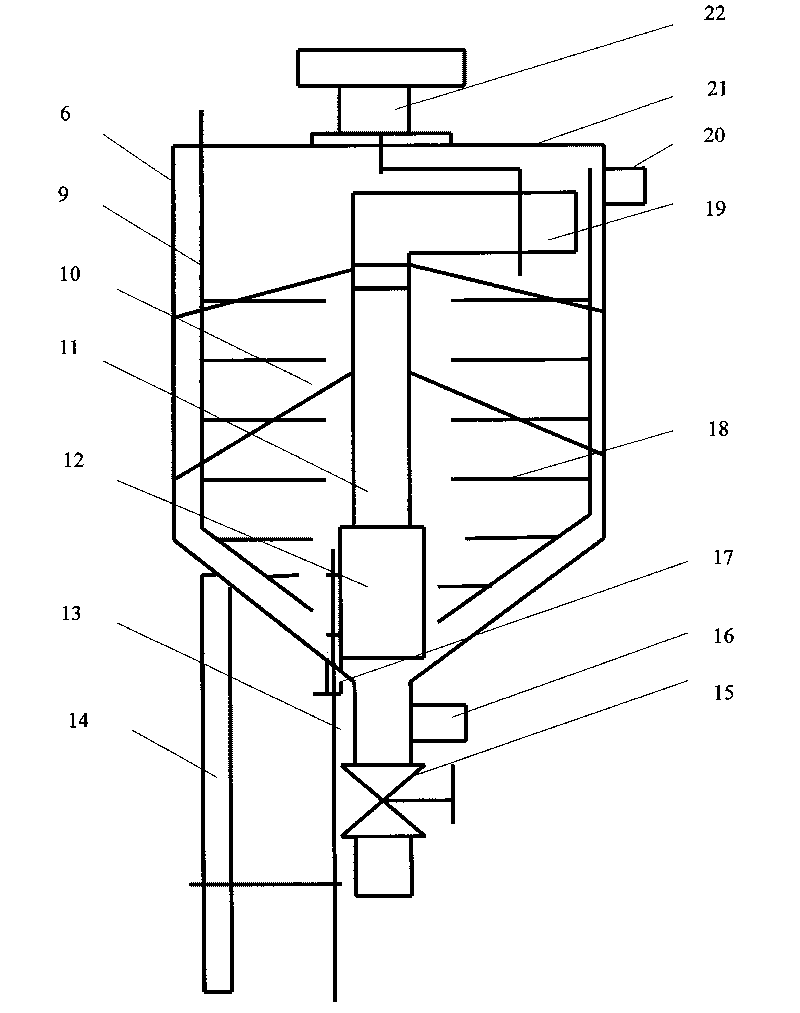

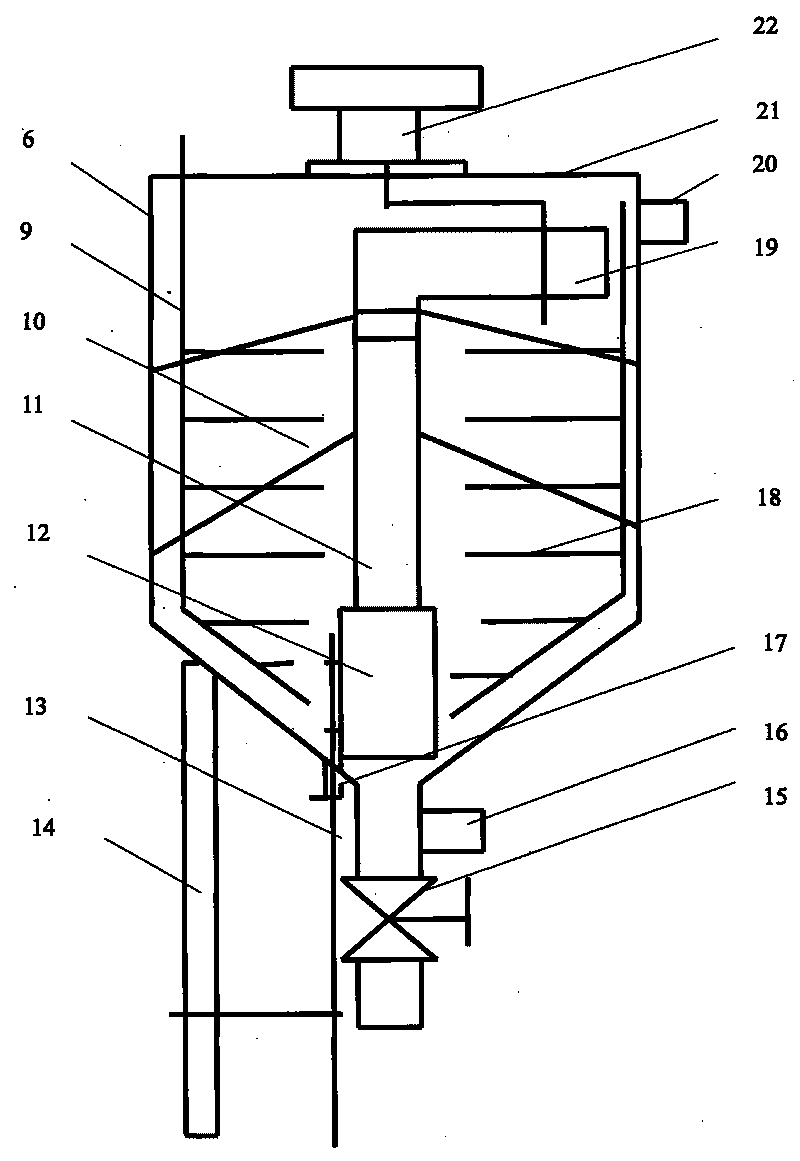

[0034] The whole device is composed of a spray fan 1, a supplementary air fan 2, a spray heater 3, a supplementary air heater 4, a hopper plus a screw feeder 5, a new spouted bed 6, a cyclone separator 7 and a bag filter 8. Such as figure 1 shown.

[0035] The connection relationship between the various parts of the whole device process is: the spray fan 1 is connected with the spray heater 3, and then connected with the new spouted bed 6; the exhaust gas outlet pipe 20 is separated from the cyclone above the top cover of the new spouted bed 6 The device 7 is connected, and the bag filter 8 is connected after the cyclone separator 7. The supplementary air fan 2 is connected with the supplementary air heater 4, and then connected to the supplementary air main pipe 9 of the novel spouted bed through a pipeline. The hopper plus screw feeder 5 is connected with the new spouted bed 6 to provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com