Snakeheaded fish feeding stuff and preparation method thereof

A feed, snakehead technology, applied in the direction of animal feed, animal feed, application, etc., to achieve the effect of balanced nutrition, scientific preparation, and sufficient raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

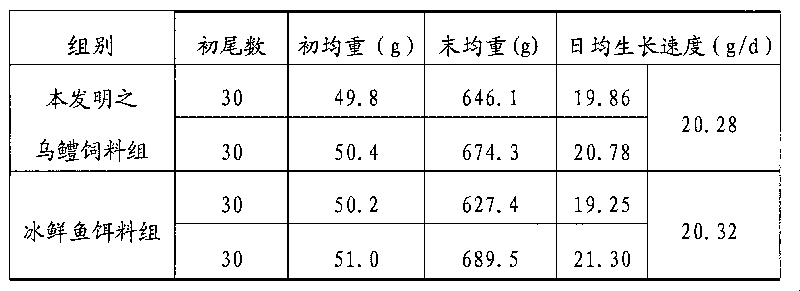

Image

Examples

Embodiment 1

[0033] Weigh 40 parts by weight of fish meal, 12 parts by weight of soybean meal, 2 parts by weight of shrimp powder, 4 parts by weight of meat meal, 3 parts by weight of molasses yeast, 7 parts by weight of fish oil, 1 part by weight of calcium dihydrogen phosphate, 2 parts by weight of premix, flour 20 parts by weight, and the premix is a commercially available freshwater fish premix produced by Beijing Tianyifeng Animal Husbandry Science and Technology Development Center.

[0034] The preparation method is to mix all raw materials except the premix and fish oil, and after mixing evenly, ultrafinely pulverize all the raw materials to pass through a 40-mesh sieve; then add the premix and fish oil, and mix evenly again; The raw material is sent into the biaxial differential speed modulator, and the water vapor of 95°C is passed through for 5 minutes; then the raw material is sent to the extruder extruder granulator at a temperature of 98°C; finally, at a temperature of 100°C,...

Embodiment 2

[0036] Weigh 50 parts by weight of fish meal, 8 parts by weight of soybean meal, 4 parts by weight of shrimp meal, 2 parts by weight of meat meal, 5 parts by weight of molasses yeast, 5 parts by weight of fish oil, 1 part by weight of calcium dihydrogen phosphate, 2.5 parts by weight of premix, flour 16 parts by weight, and the premix is a commercially available freshwater fish premix produced by Beijing Tianyifeng Animal Husbandry Science and Technology Development Center.

[0037] The preparation method is as follows: mix all raw materials except the premix and fish oil, and after mixing evenly, ultrafinely pulverize each raw material to pass through a 20-mesh sieve; then add the premix and fish oil, and mix evenly again; The material is sent into the biaxial differential speed modulator, and the steam at 90°C is passed through for 5 minutes; then the material is sent to the extrusion extruder granulator at a temperature of 90°C; finally, at a temperature of 93°C, the The ...

Embodiment 3

[0039] Weigh 45 parts by weight of fish meal, 10 parts by weight of soybean meal, 3 parts by weight of shrimp meal, 3 parts by weight of meat meal, 4 parts by weight of molasses yeast, 6 parts by weight of fish oil, 1 part by weight of calcium dihydrogen phosphate, 2.3 parts by weight of premix, flour 18 parts by weight, and the premixed material is a commercially available freshwater fish premixed material produced by Beijing Tianyifeng Animal Husbandry Science and Technology Development Center.

[0040] The preparation method is as follows: mix all raw materials except the premix and fish oil, and after mixing uniformly, ultrafinely pulverize each raw material to pass through a 50-mesh sieve; then add the premix and fish oil, and mix evenly again; The material is fed into the biaxial differential speed modulator, and 93°C steam is passed through for 6 minutes; then the material is sent to the extrusion extruder granulator at a temperature of 94°C; finally, at a temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com