Turntable robot welding system

A robot welding and turntable technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor operation flexibility, endangering the health of employees, and affecting the working environment, etc. Small, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

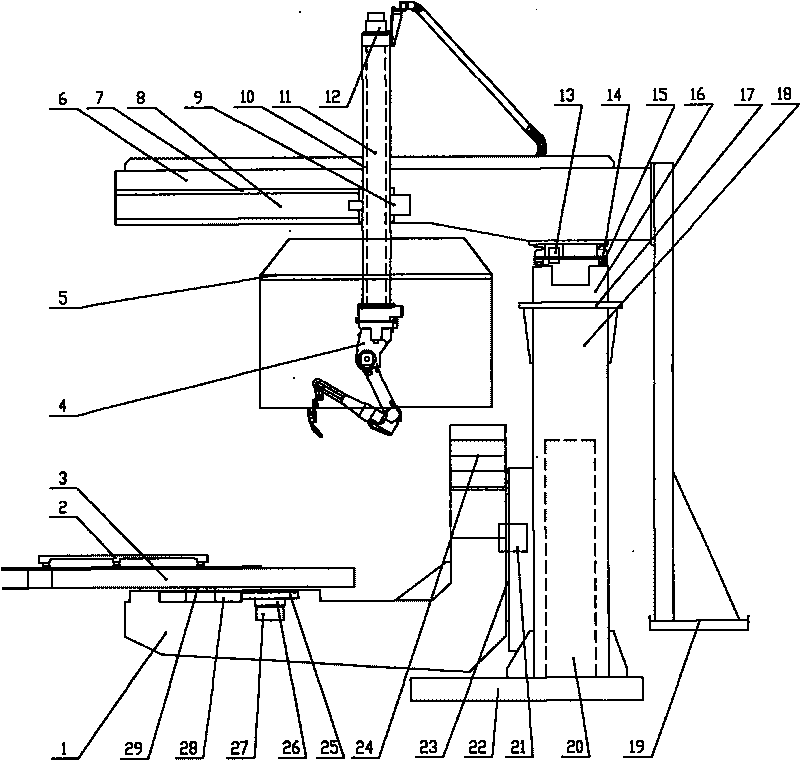

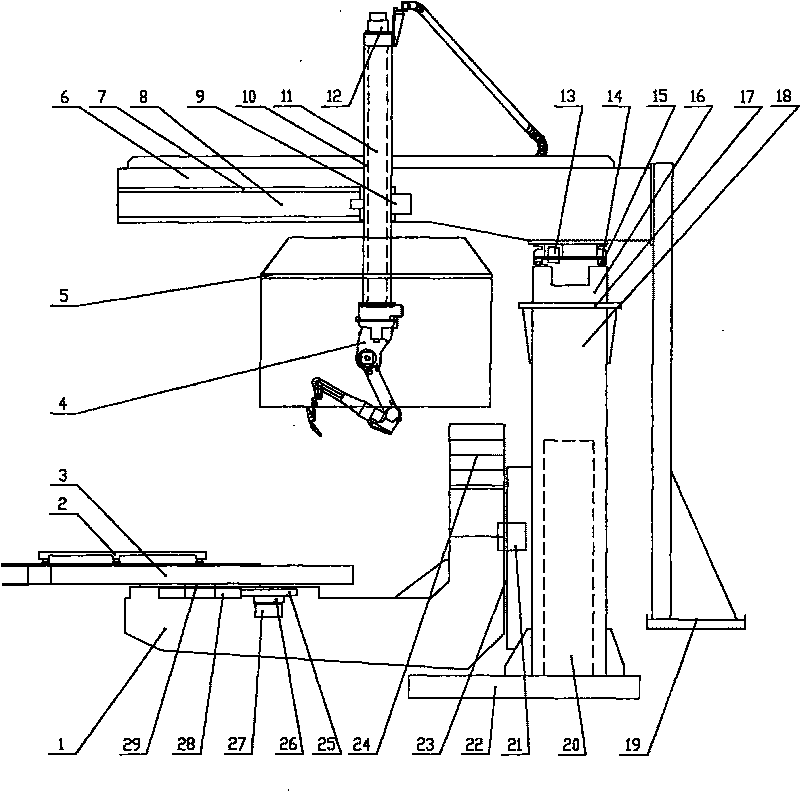

[0011] Referring to the accompanying drawings, the turntable robot welding system of the present invention is mainly composed of a three-axis moving device 6, a sky crane robot 4, a dust removal device 5, a two-axis positioner 1, a turntable fixture 3 and a central support.

[0012] The central support is composed of two columns 18 fixed on the base 22, a beam 16 fixedly connected to the top of the two columns 18 through a connecting plate 17, and the front and rear axle slide rails 15 of the three-axis moving device 6 are mounted on the beam 16.

[0013] The three-axis moving device 6 is slidably installed on the front and rear axle slide rails 15 through the front and rear axles 14 fixed to its main body, and the left and right axle slide rails 7 placed horizontally are installed on its main body, and the left and right axle slide rails 7 are slidabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com